35

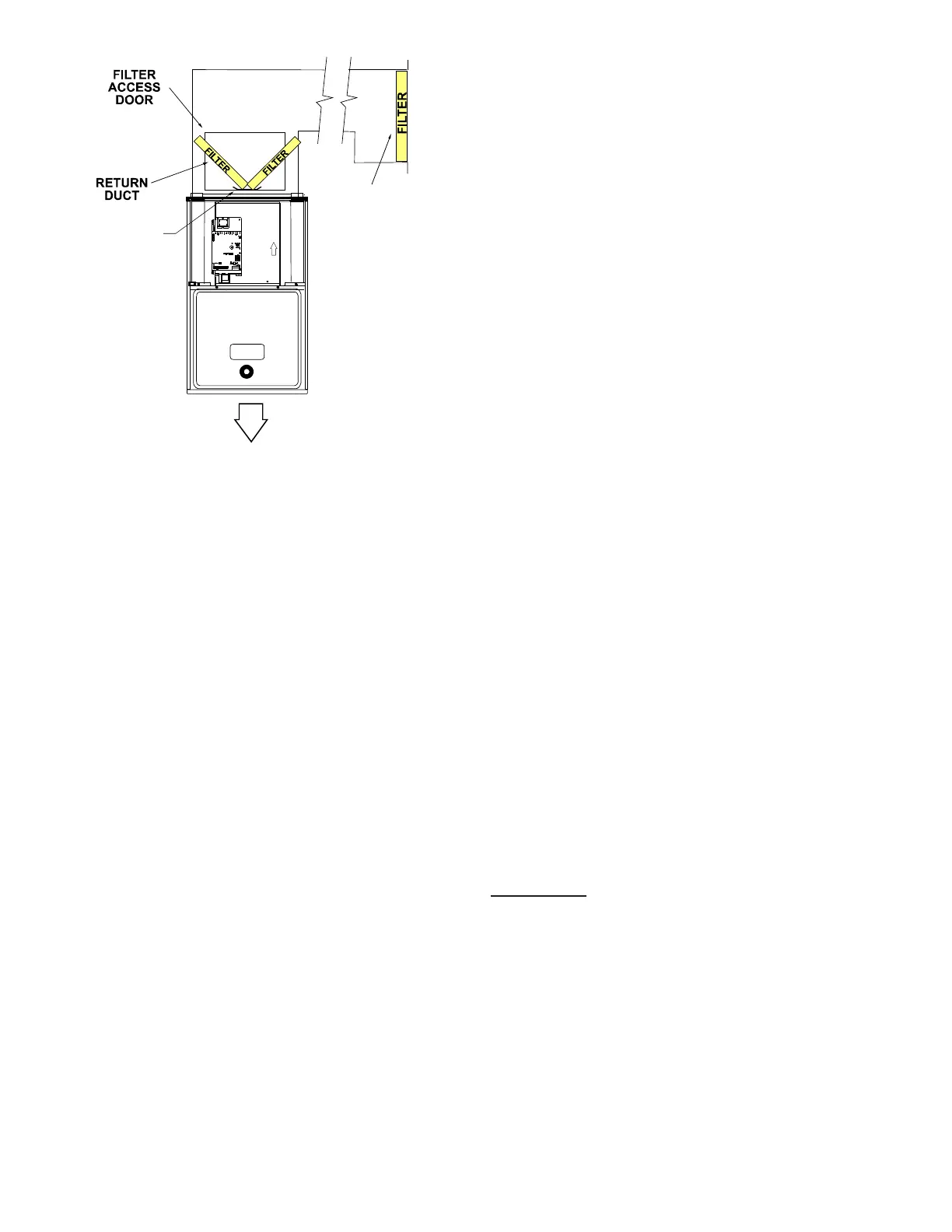

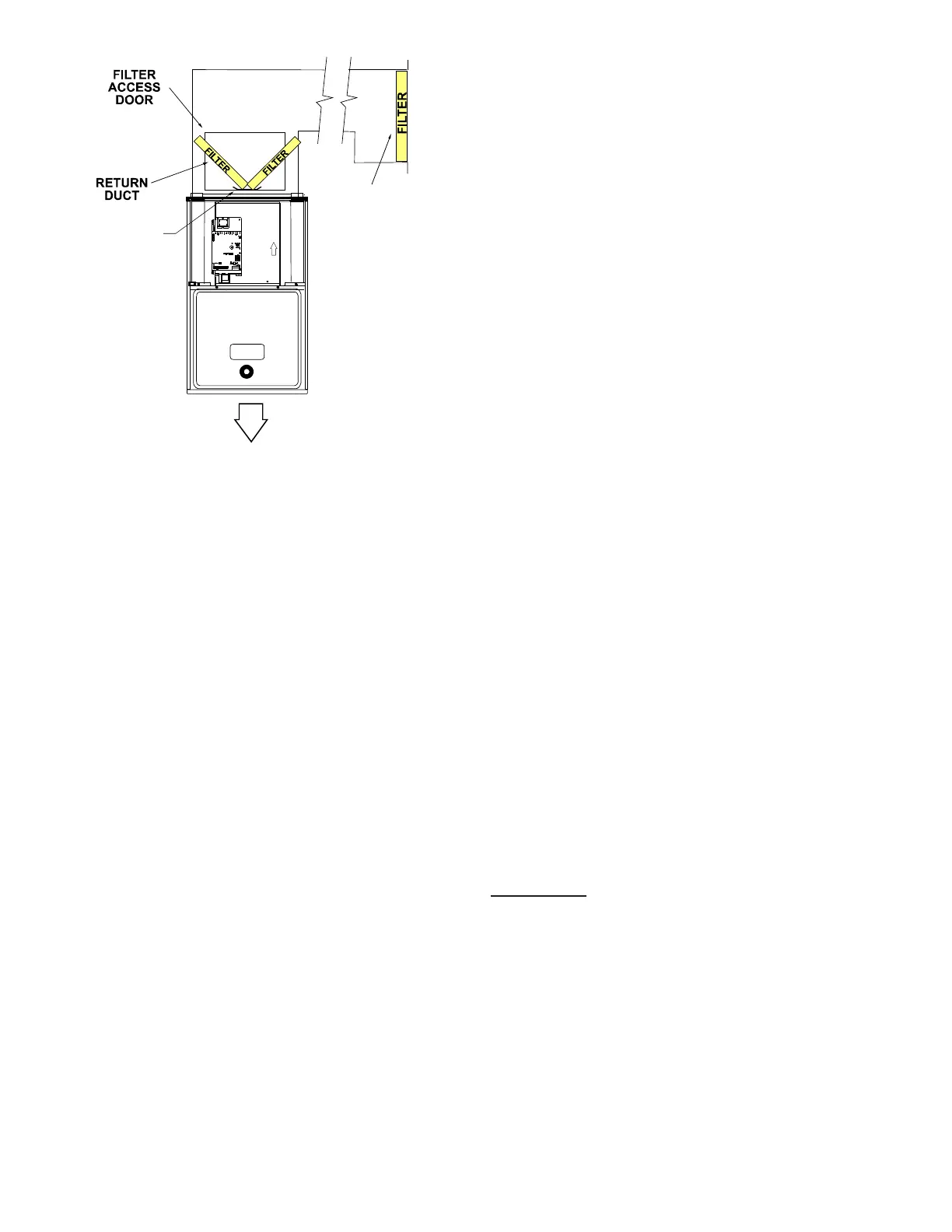

Filters must be installed in either the central return

register or in the return air duct work.

Furnace must have a 115 VAC power supply properly

connected and grounded. Proper polarity must be

maintained for correct operation. In addition to the

following start-up and adjustment items, refer to further

information in Operational Checks section.

Check that all furnace cabinet sealing components are in

place (plugs, grommets, gaskets). NOTE; If the furnace

bottom panel has not been removed for a return duct

connection, all perforations must be sealed with duct

sealant compound or other suitable method to prevent

air leakage. For optimal performance verify that all do

gaskets are properly in place and replace as needed to

prevent air

leakage.

The drain trap must be primed prior to furnace startup.

To prime, ll both sides of the drain trap with water.

This ensures proper furnace drainage upon startup and

prohibits the possibility of ue gases escaping through

the drain system.

Purge gas lines of air prior to startup. Be sure not purge

lines into an enclosed burner compartment. Follow

NFPA 54, National Fuel Gas Code 8.1 for proper purging

methods. In Canada, follow approved purging methods in

B149.1-15.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector,

or other approved method. Verify that all required kits

(propane gas, high altitude, etc.) have been appropriately

installed.

1. Close the manual gas shuto valve external to the

furnace.

2. Turn o the electrical power to the furnace.

3. Set the room thermostat to the lowest possible

setting.

4. Remove the burner compartment door.

5. Move the furnace gas valve manual control to the

OFF position.

6. Wait ve minutes then smell for gas. Be sure check

near the oor as some types of gas are heavier than

air.

7. If you smell gas after ve minutes, immediately

follow the safety instructions in the Safety

Considerations on page 2 of this manual. If you do

not smell gas after ve minutes, move the furnace

gas valve manual control to the ON position.

8. Replace the burner compartment door.

9. Open the manual gas shuto valve external to the

furnace.

10. Turn on the electrical power to the furnace.

11. Adjust the thermostat to a setting above room

temperature.

12. After the burners are lit, set the thermostat to

desired temperature.

• On a call for heat, the thermostat contacts close & the

control board receives 24 VAC on the W terminal.

• The control board microcomputer runs its self-check

routine.

• The control veries the limit switch is closed (24 VAC

on Pin 8 of the 12 Pin connector).

• The control veries that pressure switch circuit is

open (0 VAC on Pin 5).

• The control module performs a gas valve circuitry

check to verify gas valve relay state and presence of

voltage at the valve.

• The system will energize the Induced draft blower.

• The pre-purge period begins once the pressure

switch is detected closed (24 VAC on Pin 5).

Loading...

Loading...