4-1

4. Service and maintenance

4.1 Main components and

maintenance

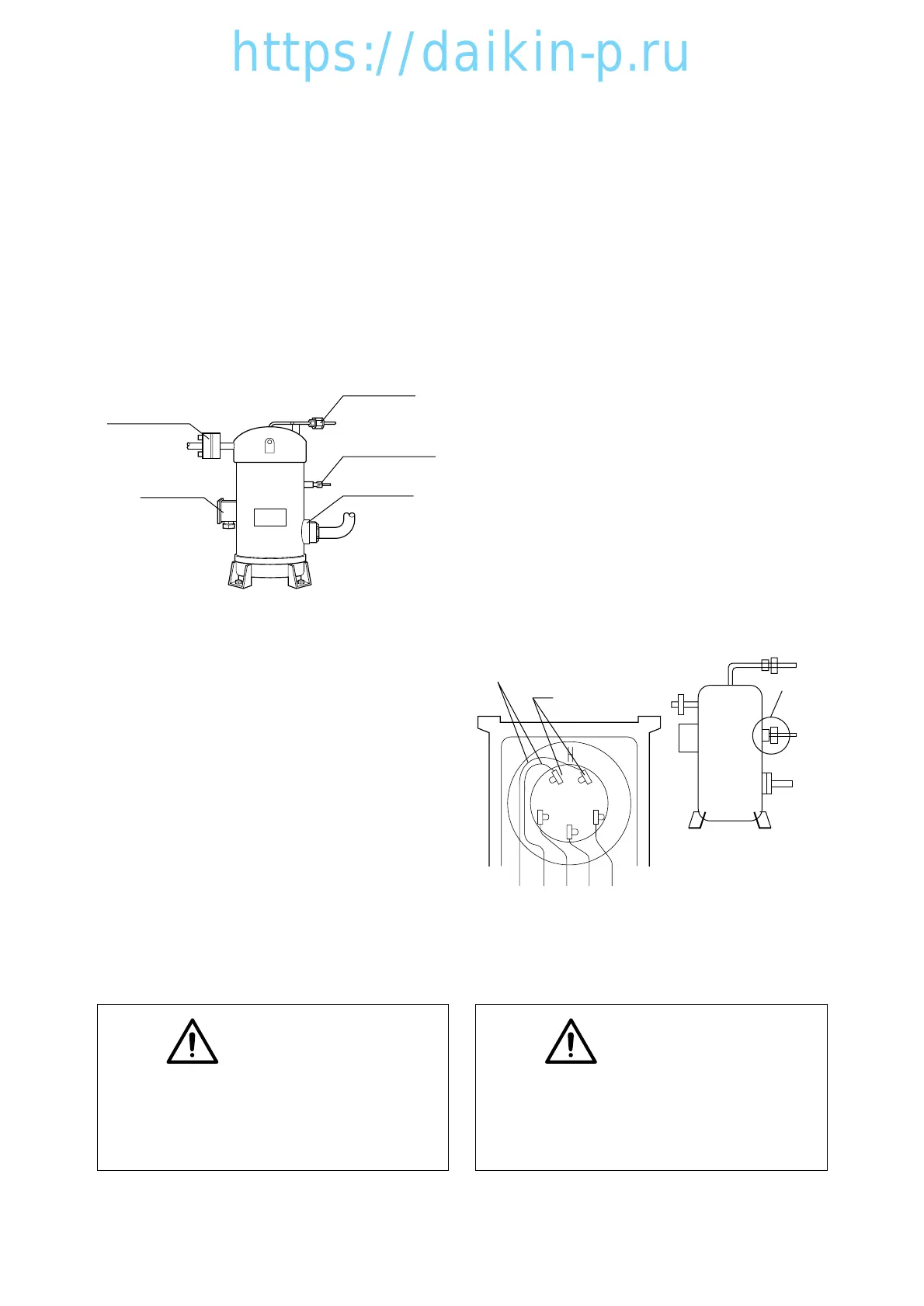

4.1.1 Scroll compressor

The compressor is of a hermetic scroll type

with the built-in motor so that there are less

places where refrigerant may leak. No

refrigerant oil is required when the unit is new

because it has been charged before delivery.

(1) Removal of compressor

q Collect the refrigerant from the quick joints on

discharge pressure regulating valve inlet and

liquid receiver outlet.

Refer to the section "4.4. Maintenance

service" on page 4-16 for refrigerant collecting

method.

w Switch off the power.

e Open the terminal box cover to disconnect

the wires.

r Remove the bolts for suction flange and

discharge flange.

t Remove the flare nut for the intermittent

injection and gauge piping.

y Remove the compressor mounting bolts.

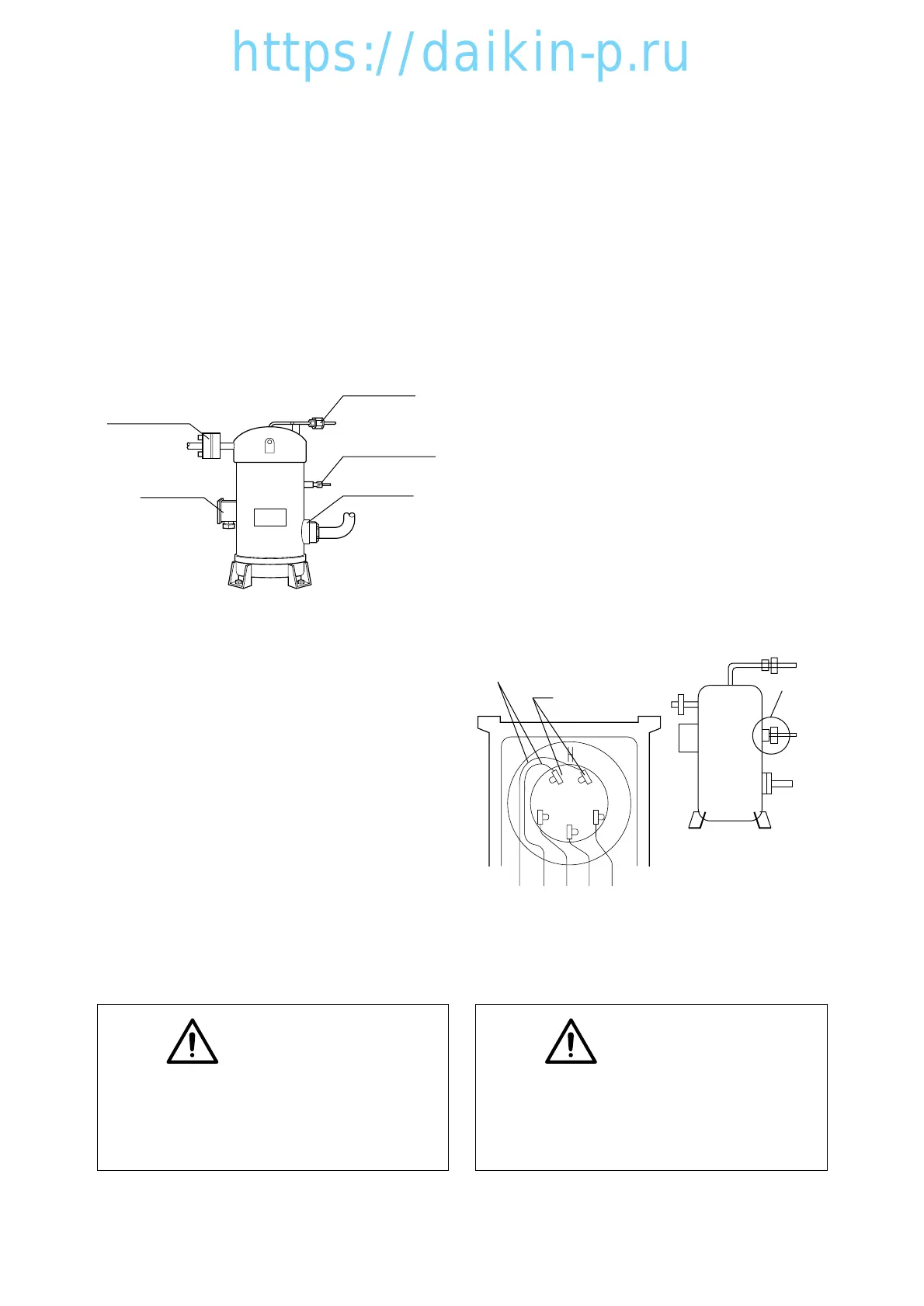

Yellow

132

Grey

131

Red

22

White

23

Black

24

– Wire color

– Wire number

W

V

U

CTP

Lay wires on the left side

of the terminal board.

Seal with

silicon

sealant

CAUTION

The unit does not have suction stop

valve. Be sure to adhere packing tape at

suction piping section to prevent

moisture from entering.

CAUTION

The preparation of refrigerant oil is not

required.

The compressor has been charge with

the oil.

Suction flange

Discharge flange

Terminal box

Flare nut for gauge

piping

Flare nut for

injection piping

(2) Installation of compressor

q Fix the compressor base with bolts

Tightening torque: 42.7N m(435 kgf cm)

w Apply new gaskets to the suction and

discharge flange and fix them with bolts

Tightening torque for the suction flange:

25.2N m(257 kgf cm)

Tightening torque for the discharge flange:

25.2N m(257 kgf cm)

e Tighten the flare nut for intermittent injection

and gauge piping.

Tightening torque : φ6.4 : 15.7 N m

(160 kgf cm)

φ9.5 : 36.3 N m

(370 kgf cm)

r Connect wires to the terminals and put the

cover on.

Pay the utmost attention to the wiring of the

compressor. Incorrect wiring may run the

compressor in wrong direction and may cause

burn out

t Apply a silicon sealant on the flare nut section

of gauge piping.

Loading...

Loading...