Required tools

You can perform the service procedures described in this manual using common mechanic’s tools.

Special tools, if required are shown. Use calibrated pressure gauges to ensure accuracy. Use snubbers to

protect pressure gauges.

Port locations and gauge installation

The following sections list the ports for each type of hydraulic unit. The fitting size and recommended

pressure gauge are also specified.

The following table and drawings show the port locations and gauge sizes needed.

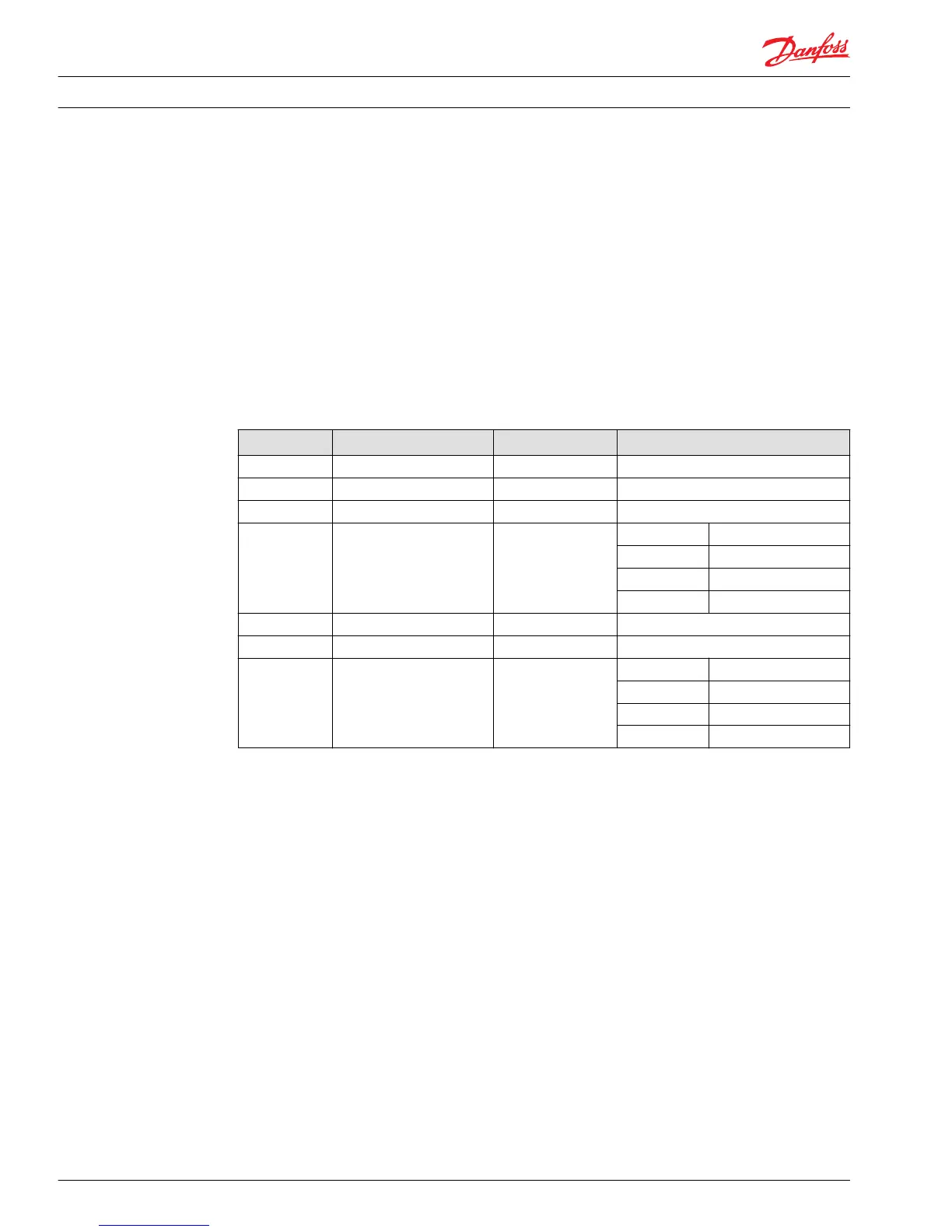

Port information

Port identifier Pressure obtained Gauge size Port size

M1, M2 System pressure 1000 bar [10 000 psi] 9/16-18

M3 (M6) Charge pressure 50 bar [1000 psi] 9/16-18

M4, M5 Servo pressure 50 bar [1000 psi] 9/16-18

L1, L2 Case pressure 10 bar [100 psi] 030-042 7/8-14

055-100 1-1/16-12

130 1-5/16-12

180-250 1-5/8-12

X1, X2 HDC/EDC control pressure 50 bar [1000 psi] 7/16-20 or 9/16-18

X3 External control pressure 50 bar [1000 psi] 9/16-18

S Charge pump inlet Vacuum gauge,

Tee into inlet line

030-042 1-1/16-12

055-075 1-5/16-12

100-180 1-5/8-12

250 1-1/2 SAE-split flange

Service Manual Series 90 Pumps

Pressure measurement

22 520L0818 • Rev 0101 • August 2015

Loading...

Loading...