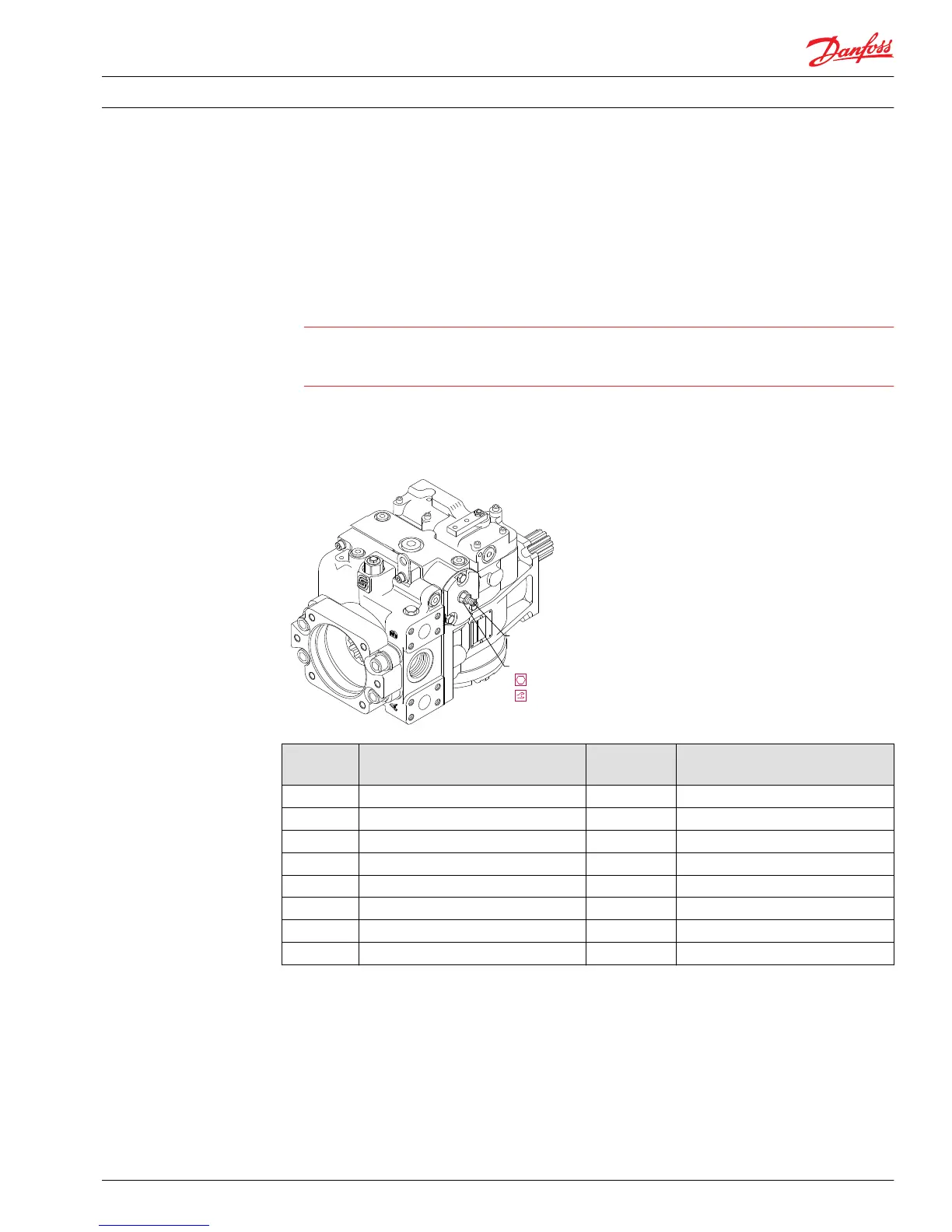

Displacement limiter adjustment

You can limit the maximum displacement in either direction.

1. Loosen the lock nut (F212) while holding the adjusting screw (F213) steady.

2. Rotate the adjusting screw some amount (using information in the following table). Rotating the

adjusting screw clockwise decreases the maximum displacement of the pump while rotating the

adjusting screw counterclockwise increases the maximum displacement.

Caution

Take care in adjusting displacement limiters to avoid undesirable flow or speed conditions. Re-torque

lock nut (F212) after every adjustment to prevent an unexpected change in operating conditions and

to prevent external leakage during unit operation.

3. One turn of the adjusting screw changes the maximum displacement as shown in table below

4. After establishing the desired maximum displacement setting, torque the lock nut to the torque

shown in table below.

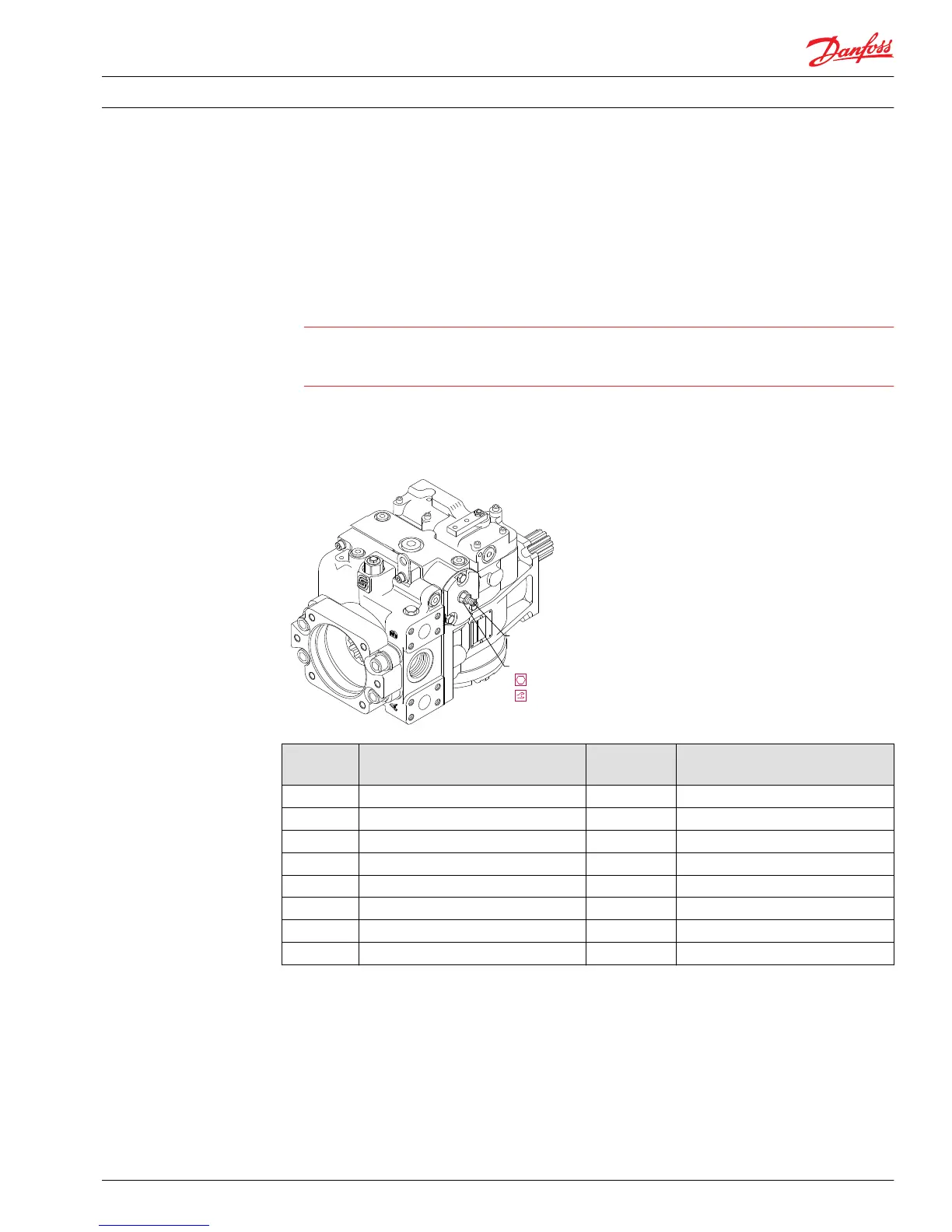

Displacement limiter adjustment

Frame size Lock nut wrench size and torque Adjusting

screw size

Approximate displacement change

per revolution of adjusting screw

030 13 mm 24 N•m [18 lbf•ft] 4 mm 2.8 cm³/(rev) [0.17 in³/rev]

042 13 mm 24 N•m [18 lbf•ft] 4 mm 3.5 cm³/(rev) [0.21 in³/rev]

055 13 mm 24 N•m [18 lbf•ft] 4 mm 4.2 cm³/rev [0.26 in³/rev]

075 13 mm 24 N•m [18 lbf•ft] 4 mm 5.1 cm³/rev [0.31 in³/rev]

100 13 mm 24 N•m [18 lbf•ft] 4 mm 6.2 cm³/rev [0.38 in³/rev]

130 17 mm 48 N•m [35 lbf•ft] 5 mm 8.8 cm³/rev [0.53 in³/rev]

180 19 mm 125 N•m [92 lbf•ft] 6 mm 12.5 cm³/rev [0.76 in³/rev]

250 19 mm 125 N•m [92 lbf•ft] 6 mm 17.3 cm³/rev [1.06 in³/rev]

Standard manual displacement control (MDC) adjustment

There are no adjustable elements in the manual displacement control. Centering springs and washers on

each end of the control spool hold it in its neutral position. Since there is no centering spring on the

control input shaft, the shaft automatically assumes the appropriate position when the control is installed

on the pump.

Service Manual

Series 90 Pumps

Adjustments

520L0818 • Rev 0101 • August 2015 33

Loading...

Loading...