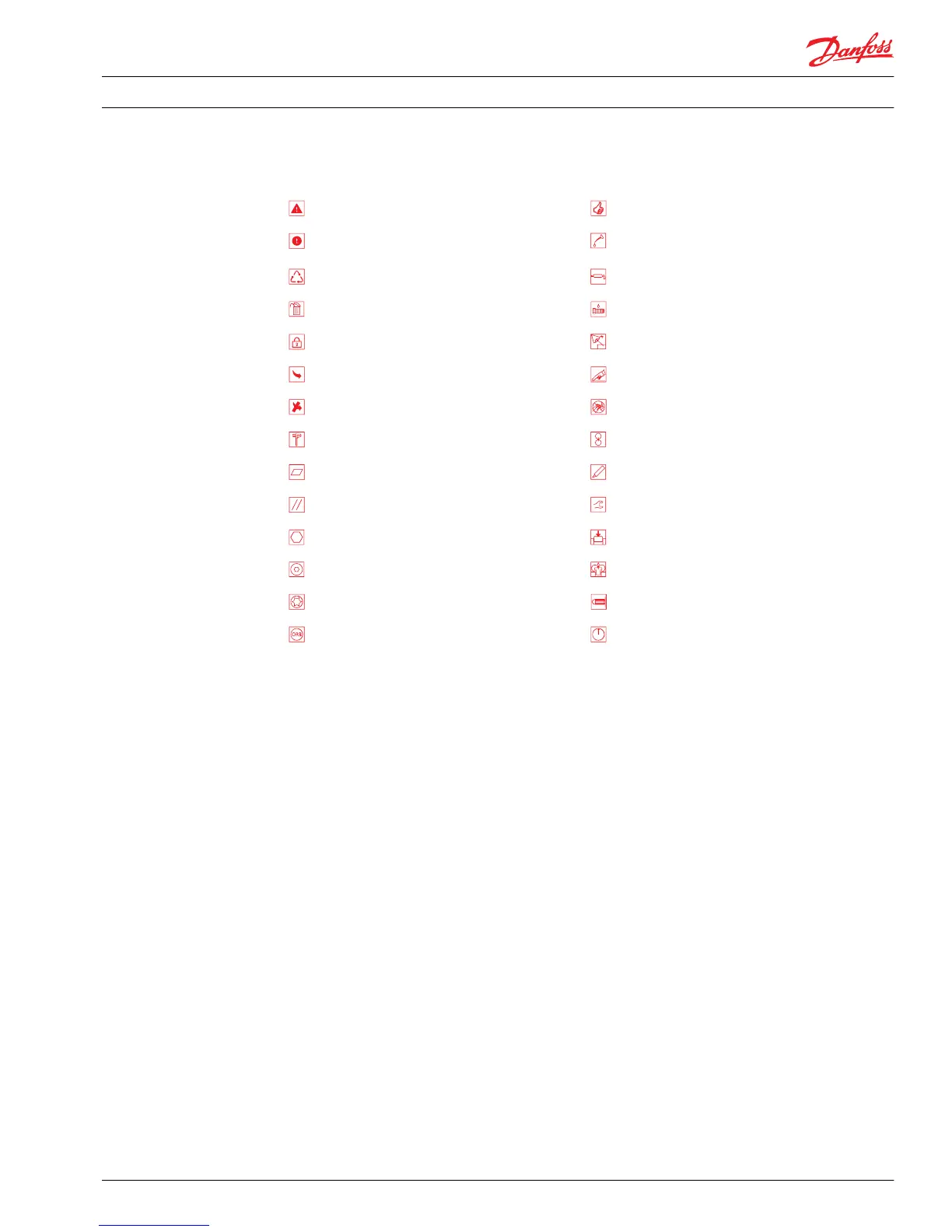

Symbols used in Danfoss literature

WARNING may result in injury Tip, helpful suggestion

CAUTION may result in damage to product or

property

Lubricate with hydraulic fluid

Reusable part Apply grease / petroleum jelly

Non-reusable part, use a new part Apply locking compound

Non-removable item Inspect for wear or damage

Option - either part may exist Clean area or part

Superseded - parts are not interchangeable Be careful not to scratch or damage

Measurement required Note correct orientation

Flatness specification Mark orientation for reinstallation

Parallelism specification Torque specification

External hex head Press in - press fit

Internal hex head Pull out with tool – press fit

Torx head Cover splines with installation sleeve

O-ring boss port Pressure measurement/gauge location or

specification

The symbols above appear in the illustrations and text of this manual. They are intended to communicate

helpful information at the point where it is most useful to the reader. In most instances, the appearance

of the symbol itself denotes its meaning. The legend above defines each symbol and explains its purpose.

Design

Danfoss Series 90 closed circuit piston pumps convert input torque into hydraulic power. The input shaft

transmits rotational force to the cylinder block. Bearings support the input shaft at the front and rear of

the pump. The shaft is splined into the cylinder block. A lip-seal at the front end of the pump prevents

leakage where the shaft exits the pump housing. The spinning cylinder block contains nine reciprocating

pistons. A ball joint at one end connects each piston to a brass slipper. Fixed-clearance hold-down

brackets keep the slippers in contact with the swashplate. The reciprocating movement of the pistons

occurs as the slippers slide against the inclined swashplate during rotation. The valve plate connects one

half of the cylinder block to low pressure and the other half to high pressure. As each piston cycles in and

out of its bore, fluid is drawn from the inlet and displaced to the outlet thereby imparting hydraulic

power into the system. A small amount of fluid flows from the cylinder block/valve plate and slipper/

swashplate interfaces for lubrication and cooling. Case drain ports return this fluid to the reservoir.

The angle of the swashplate controls the volume of fluid displaced into the system. The servo piston

forces the swashplate into an inclined position. The pump control, acting on input from the operator, by

modulating pressure balance across the servo piston, sets displacement in the system circuit.

Service Manual

Series 90 Pumps

Introduction

520L0818 • Rev 0101 • August 2015 7

Loading...

Loading...