1-04 Overload Mode

Option: Function:

[0] * High torque Allows up to 160% over torque.

[1] Normal torque For oversized motor - allows up to 110%

over torque.

NOTE

This parameter cannot be adjusted while the motor is

running.

1-90 Motor Thermal Protection

Option: Function:

Thermal motor protection can be

implemented using a range of techniques:

•

Via a PTC sensor in the motor

windings connected to one of the

analog or digital inputs

(1-93 Thermistor Source). See

6.1.3.1 PTC Thermistor Connection.

•

Via a KTY sensor in the motor

winding connected to an analog

input (1-96 KTY Thermistor Resource).

See 6.1.3.2 KTY Sensor Connection.

•

Via calculation (ETR = Electronic

Thermal Relay) of the thermal load,

based on the actual load and time.

The calculated thermal load is

compared with the rated motor

current I

M,N

and the rated motor

frequency f

M,N

. See 6.1.3.3 ETR and .

•

Via a mechanical thermal switch

(Klixon type). See 6.1.3.4 ATEX ETR.

For the North American market: The ETR

functions provide class 20 motor overload

protection in accordance with NEC.

[0]

* No

protection

Continuously overloaded motor, when no

warning or trip of the frequency converter is

required.

[1] Thermistor

warning

Activates a warning when the connected

thermistor or KTY-sensor in the motor reacts

in the event of motor over-temperature.

[2] Thermistor

trip

Stops (trips) frequency converter when

connected thermistor or KTY sensor in the

motor reacts in the event of motor over-

temperature.

The thermistor cut-out value must be > 3

kΩ.

Integrate a thermistor (PTC sensor) in the

motor for winding protection.

[3] ETR warning

1

Calculates the load when set-up 1 is active

and activates a warning on the display when

1-90 Motor Thermal Protection

Option: Function:

the motor is overloaded. Programme a

warning signal via one of the digital outputs.

[4] ETR trip 1 Calculates the load when set-up 1 is active

and stops (trips) frequency converter when

the motor is overloaded. Programme a

warning signal via one of the digital outputs.

The signal appears in the event of a warning

and if the frequency converter trips (thermal

warning).

[5] ETR warning

2

[6] ETR trip 2

[7] ETR warning

3

[8] ETR trip 3

[9] ETR warning

4

[10] ETR trip 4

NOTE

If [20] is selected, follow strictly the instructions described

in the dedicated chapter of the VLT AutomationDrive

design guide and the instructions given by the motor

manufacturer.

NOTE

If [20] is selected, 4-18 Current Limit must be set to 150%.

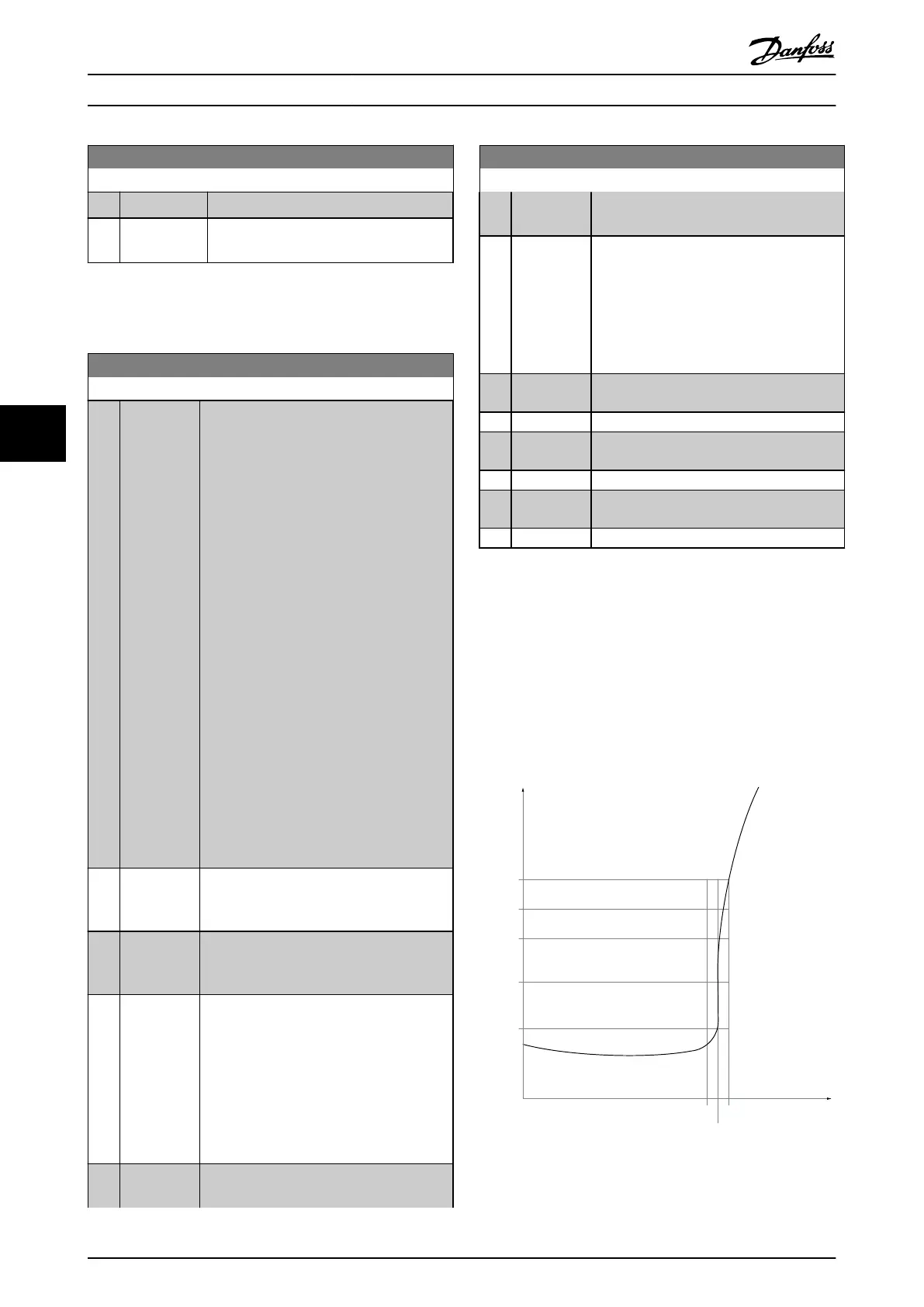

6.1.3.1 PTC Thermistor Connection

1330

550

250

-20°C

175HA183.10

4000

3000

R

(Ω)

nominel

nominel -5°C

nominel +5°C

[°C]

Illustration 6.2 PTC profile

Using a digital input and 10 V as power supply:

How to Programme the Low Ha... VLT Automation Low Harmonic Drive Operating Instructions

70 MG34O202 - VLT

®

is a registered Danfoss trademark

6

6

Loading...

Loading...