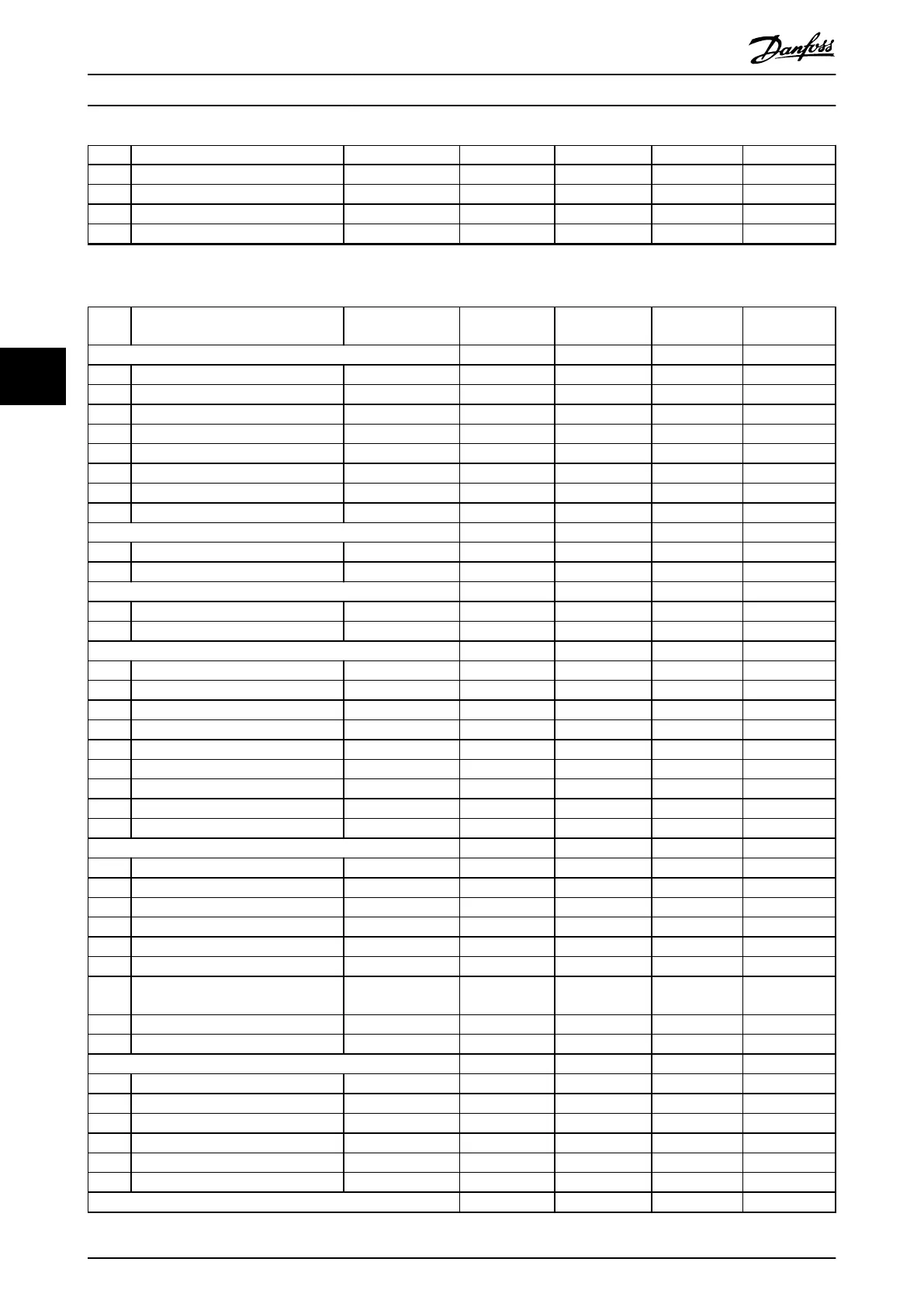

6-92 Terminal 42 Digital Output [0] No operation All set-ups TRUE - Uint8

6-93 Terminal 42 Output Min Scale 0 % All set-ups TRUE -2 Uint16

6-94 Terminal 42 Output Max Scale 100 % All set-ups TRUE -2 Uint16

6-96 Terminal 42 Output Bus Control 0 N/A All set-ups TRUE 0 Uint16

6-98 Drive Type 0 N/A 1 set-up FALSE 0 Uint8

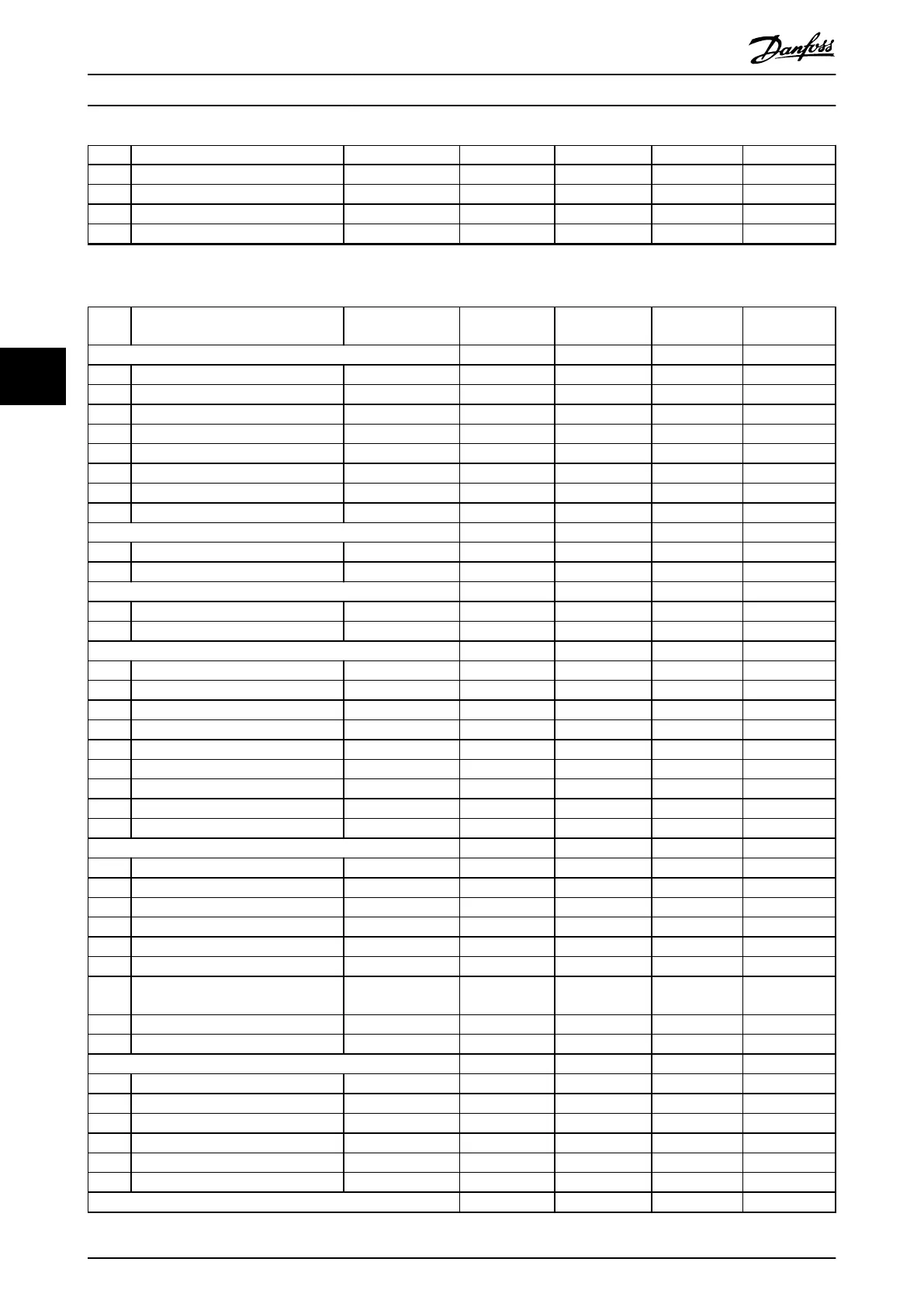

5.2.8 7-** Controllers

Param

eter #

Parameter description Default value 4 set-up Change during

operation

Conversion

index

Type

7-0* Speed PID Ctrl.

7-00 Speed PID Feedback Source [20] None All set-ups FALSE - Uint8

7-02 Speed PID Proportional Gain 0.015 N/A All set-ups TRUE -3 Uint16

7-03 Speed PID Integral Time 8 ms All set-ups TRUE -4 Uint32

7-04 Speed PID Dierentiation Time 30 ms All set-ups TRUE -4 Uint16

7-05 Speed PID Di. Gain Limit 5 N/A All set-ups TRUE -1 Uint16

7-06 Speed PID Lowpass Filter Time 10 ms All set-ups TRUE -4 Uint16

7-07 Speed PID Feedback Gear Ratio 1 N/A All set-ups FALSE -4 Uint32

7-08 Speed PID Feed Forward Factor 0 % All set-ups FALSE 0 Uint16

7-1* Torque PID Ctrl.

7-12 Torque PID Proportional Gain 100 % All set-ups TRUE 0 Uint16

7-13 Torque PID Integration Time 0.020 s All set-ups TRUE -3 Uint16

7-2* Process Ctrl. Feedb

7-20 Process CL Feedback 1 Resource [0] No function All set-ups TRUE - Uint8

7-22 Process CL Feedback 2 Resource [0] No function All set-ups TRUE - Uint8

7-3* Process PID Ctrl.

7-30 Process PID Normal/ Inverse Control [0] Normal All set-ups TRUE - Uint8

7-31 Process PID Anti Windup [1] On All set-ups TRUE - Uint8

7-32 Process PID Start Speed 0 RPM All set-ups TRUE 67 Uint16

7-33 Process PID Proportional Gain 0.01 N/A All set-ups TRUE -2 Uint16

7-34 Process PID Integral Time 9999 s All set-ups TRUE -2 Uint32

7-35 Process PID Dierentiation Time 0 s All set-ups TRUE -2 Uint16

7-36 Process PID Di. Gain Limit 5 N/A All set-ups TRUE -1 Uint16

7-38 Process PID Feed Forward Factor 0 % All set-ups TRUE 0 Uint16

7-39 On Reference Bandwidth 5 % All set-ups TRUE 0 Uint8

7-4* Adv. Process PID I

7-40 Process PID I-part Reset [0] No All set-ups TRUE - Uint8

7-41 Process PID Output Neg. Clamp -100 % All set-ups TRUE 0 Int16

7-42 Process PID Output Pos. Clamp 100 % All set-ups TRUE 0 Int16

7-43 Process PID Gain Scale at Min. Ref. 100 % All set-ups TRUE 0 Int16

7-44 Process PID Gain Scale at Max. Ref. 100 % All set-ups TRUE 0 Int16

7-45 Process PID Feed Fwd Resource [0] No function All set-ups TRUE - Uint8

7-46

Process PID Feed Fwd Normal/ Inv.

Ctrl. [0] Normal All set-ups TRUE - Uint8

7-48 PCD Feed Forward 0 N/A All set-ups TRUE 0 Uint16

7-49 Process PID Output Normal/ Inv. Ctrl. [0] Normal All set-ups TRUE - Uint8

7-5* Adv. Process PID II

7-50 Process PID Extended PID [1] Enabled All set-ups TRUE - Uint8

7-51 Process PID Feed Fwd Gain 1 N/A All set-ups TRUE -2 Uint16

7-52 Process PID Feed Fwd Ramp up 0.01 s All set-ups TRUE -2 Uint32

7-53 Process PID Feed Fwd Ramp down 0.01 s All set-ups TRUE -2 Uint32

7-56 Process PID Ref. Filter Time 0.001 s All set-ups TRUE -3 Uint16

7-57 Process PID Fb. Filter Time 0.001 s All set-ups TRUE -3 Uint16

7-6* Feedback Conversion

Parameter Lists

VLT

®

Midi Drive FC 280

122 Danfoss A/S © 12/2015 All rights reserved. MG07C102

55

Loading...

Loading...