4.2 Process Data

Use the process data part of the PPO to control and

monitor the frequency converter via the PROFIBUS.

4.2.1 Process Control Data

Process control data (PCD) is the process data sent from

the PLC to the frequency converter.

Master/slave

1 2 3 ....... 10

CTW MRV PCD ....... PCD

PCD write

Table 4.1 Process Control Data

PCD 1 contains a 16-bit control word, and each bit controls

a

specic function of the frequency converter, see

chapter 4.3 Control Prole.

PCD 2 contains a 16-bit speed setpoint in percentage

format. See chapter 4.2.3 Reference Handling.

The settings in parameter 9-15 PCD Write Conguration and

parameter 9-16 PCD Read Conguration dene the content

of PCD 3 to PCD 10.

4.2.2 Process Status Data

Process status data is the process data sent from the

frequency converter and contains information about the

current state.

Slave/master

1 2 3 ...... 10

STW MAV PCD ...... PCD

PCD read

Table 4.2 Process Status Data

PCD 1 contains a 16-bit status word, and each bit contains

information regarding a possible state of the frequency

converter.

PCD 2 contains per default the value of the current speed

of the frequency converter in percentage format (see

chapter 4.2.3 Reference Handling). PCD 2 can be congured

to contain other process signals.

The settings in parameter 9-16 PCD Read Conguration

dene the content of PCD 3 to PCD 10.

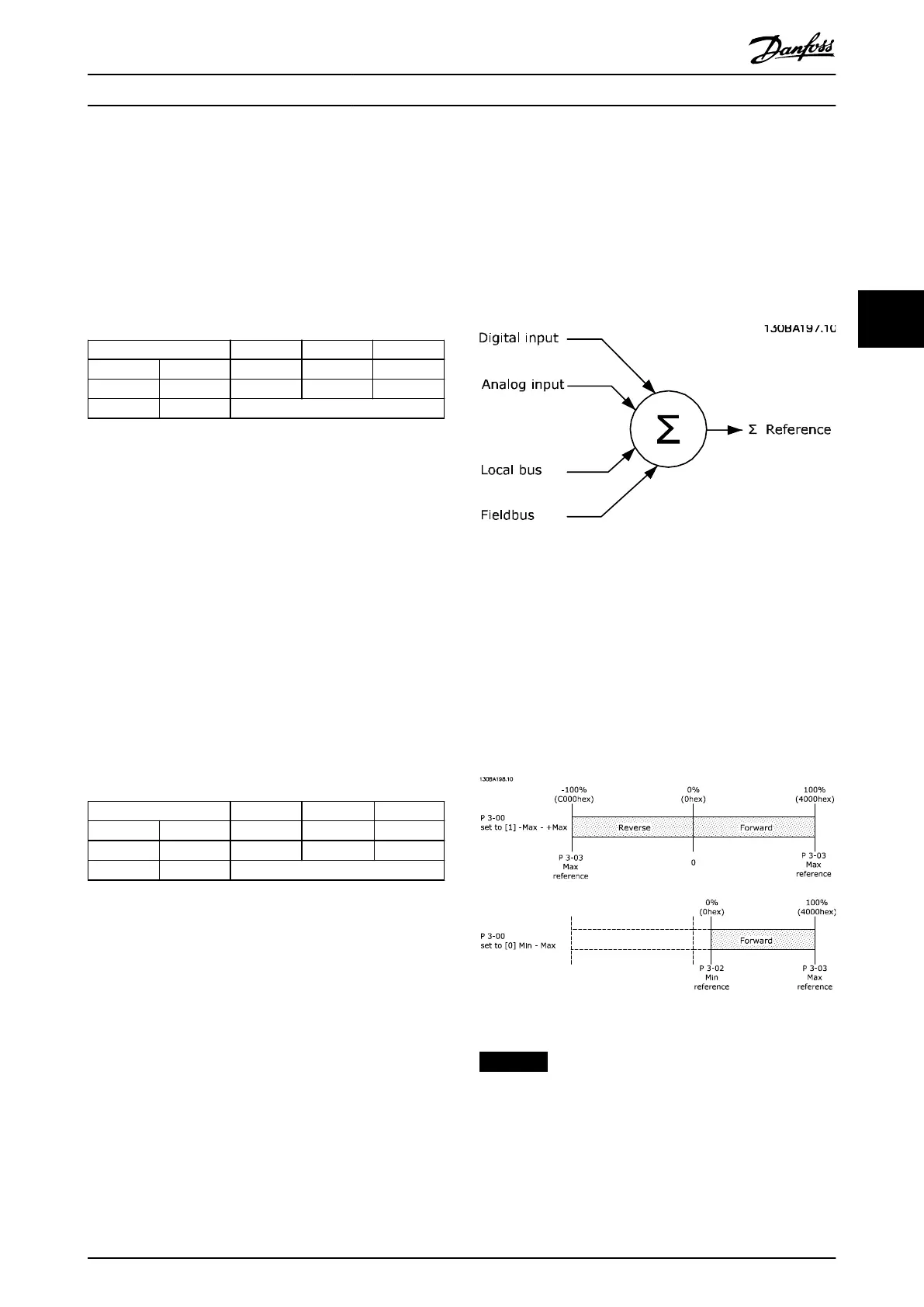

4.2.3 Reference Handling

The reference handling is an advanced mechanism that

sums up references from dierent sources, as shown in

Illustration 4.2.

For more information on reference handling, refer to the

design guide of the relevant frequency converter.

Illustration 4.2 Reference

The reference, or speed setpoint, is sent via PROFIBUS and

is always transmitted to the frequency converter in

percentage format as integers shown in hexadecimal (0–

4000 hex).

The reference (MRV) and feedback (MAV) are always scaled

equally. The setting of parameter 3-00 Reference Range

determines the scaling of the reference and feedback

(MAV), see Illustration 4.3.

Illustration 4.3 Reference (MRV) and Feedback (MAV), Scaled

NOTICE

When parameter 3-00 Reference Range is set to [0] Min -

Max, a negative reference is handled as 0%.

The actual output of the frequency converter is limited by

the speed limit parameters Motor Low/High Speed Limit

[RPM/Hz] in parameter 4-11 Motor Speed Low Limit [RPM] to

parameter 4-14 Motor Speed High Limit [Hz].

Control Programming Guide

MG37G202 Danfoss A/S © 01/2016 All rights reserved. 15

4 4