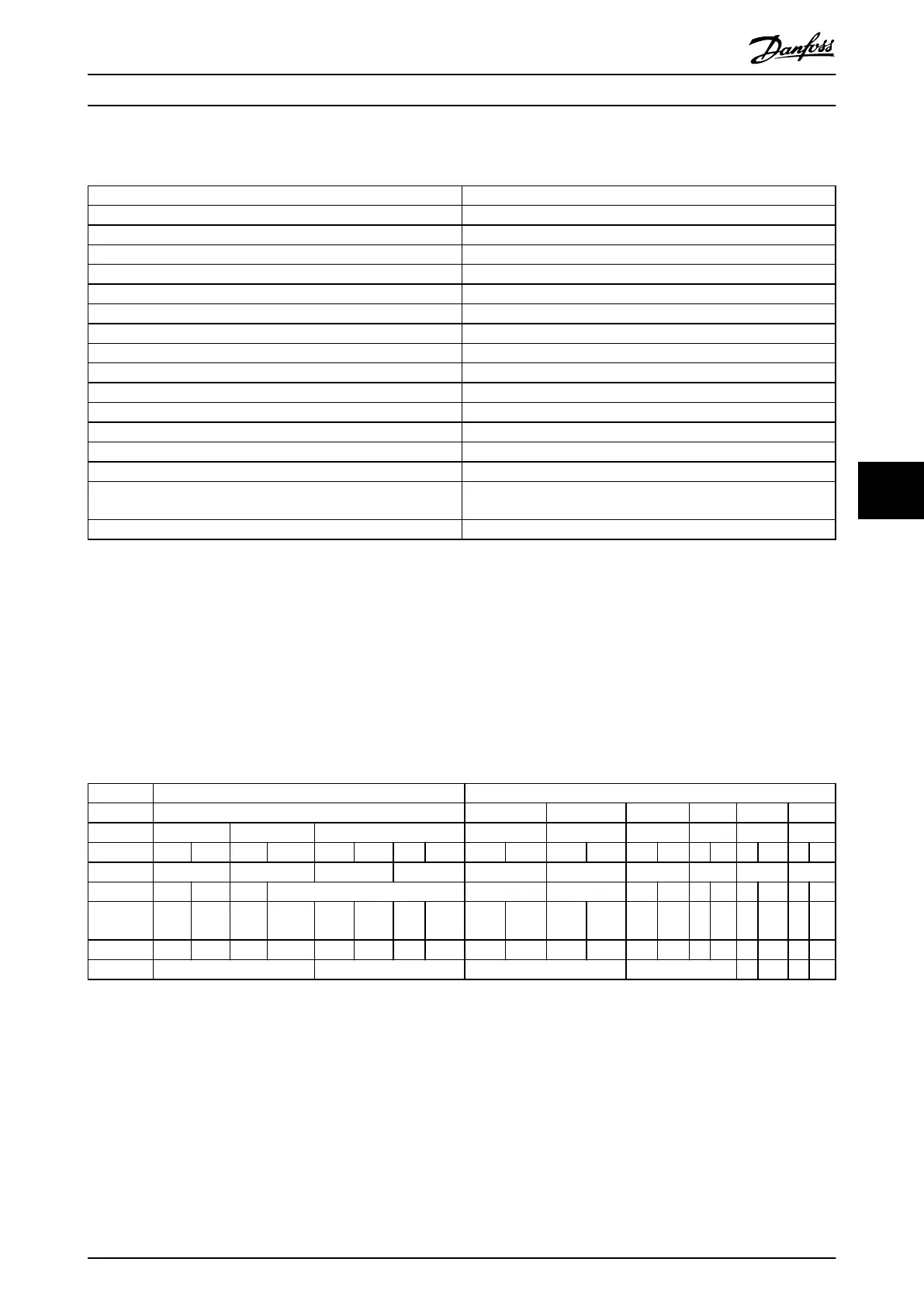

Program the frequency converter as in Table 7.2:

Parameter Setting

Parameter 4-10 Motor Speed Direction [2] Both directions

Parameter 5-10 Terminal 18 Digital Input [0] No operation

Parameter 5-11 Terminal 19 Digital Input [10] Reversing

Parameter 5-40 Function Relay [36/37] Control word bit 11/12

Parameter 8-03 Control Word Timeout Time 1 s

Parameter 8-04 Control Word Timeout Function [2] Stop

Parameter 8-10 Control Word Prole [0] FC Prole

Parameter 8-50 Coasting Select [1] Bus

Parameter 8-51 Quick Stop Select [1] Bus

Parameter 8-52 DC Brake Select [1] Bus

Parameter 8-53 Start Select [1] Bus

Parameter 8-54 Reversing Select [2] Logic AND

Parameter 8-55 Set-up Select [1] Bus

Parameter 8-56 Preset Reference Select [1] Bus

Parameter 9-16 PCD Read Conguration [2] Sub index parameter 16-16 Torque [Nm]

[3] Sub index parameter 16-60 Digital Input

Parameter 9-18 Node Address Set the address

Table 7.2 Parameter Settings

7.2

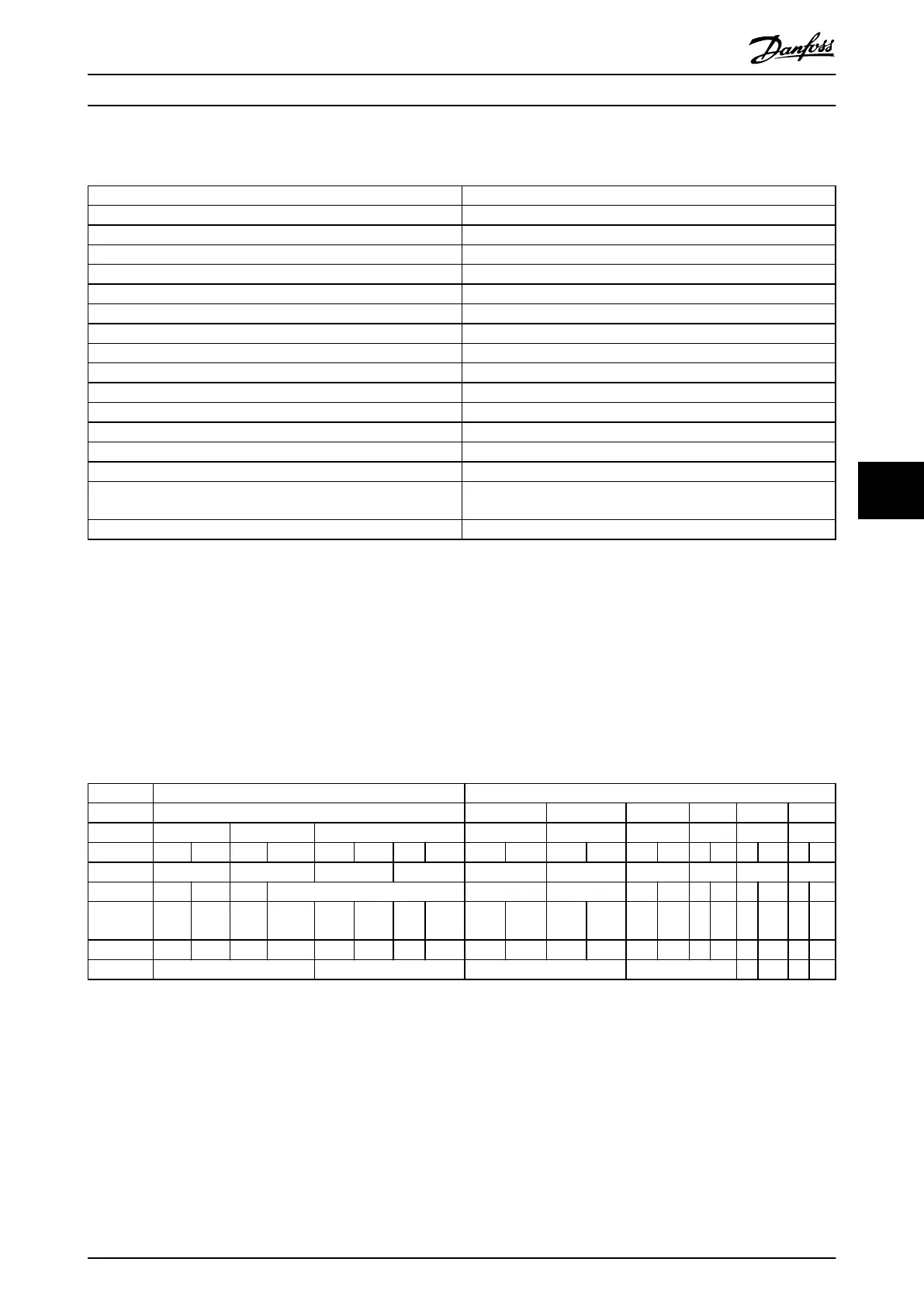

Example 2: Control Word Telegram using PPO Type

This example shows how the control word telegram relates to the PLC and the frequency converter, using FC control prole.

The PLC sends the control word telegram to the frequency converter. In the example, PPO Type 3 demonstrates the full

range of modules. All the values shown are arbitrary and are provided for demonstration purposes only.

Table 7.3 indicates the bits contained within the control word, and how they are presented as process data in PPO type 3 for

this example.

PCV PCD

1 2 3 4 5 6

PCA IND PVA CTW MRV PCD PCD PCD PCD

04 7C 20 00

PQW 256 258 260 262 264 266 268 270 272 274

master slave CTW MRV

Bit

number

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 1 0 0 0 1 1 1 1 1 0 0

0 4 7 C

Table 7.3 Example: Control Word Telegram using PPO Type

Application Examples Programming Guide

MG37G202 Danfoss A/S © 01/2016 All rights reserved. 49

7 7

Loading...

Loading...