7 Application Examples

7.1 Example 1: Process Data with PPO Type 6

This example shows how to work with PPO type 6, which consists of control word/status word and reference/main actual

value. The PPO also has 2 extra words, which can be programmed to monitor process signals:

PCV PCD

1 2 3 4 5 6 7 8 9 10

PCA IND PVA CTW MRV PCD PCD PCD PCD PCD PCD PCD PCD

STW MAV

Bit

number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Type 6

Table 7.1 Example: Process Data with PPO Type 6

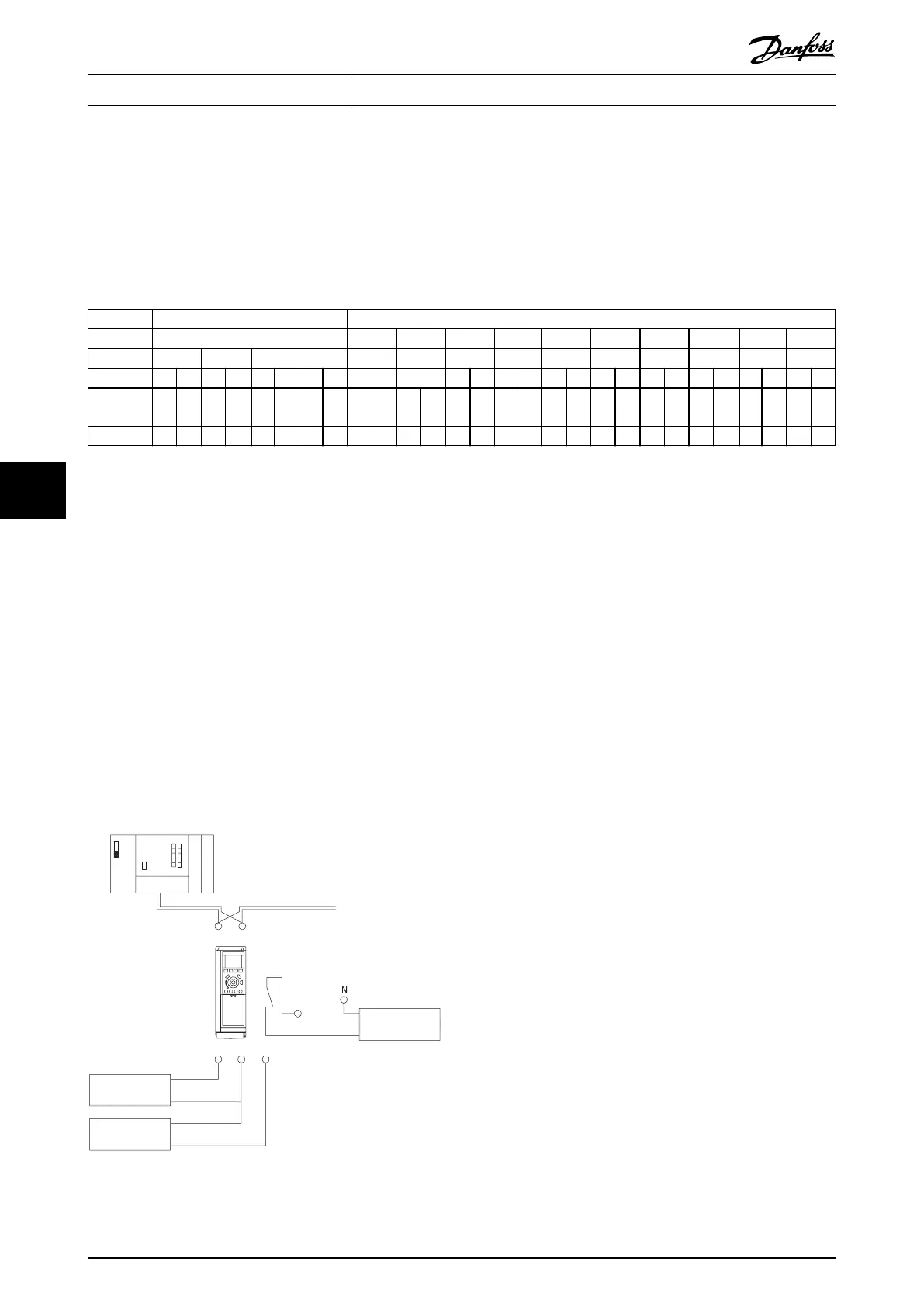

The application requires monitoring of the motor torque

and digital input, so PCD 3 is set up to read the current

motor torque. PCD 4 is set up to monitor the state of an

external sensor via the process signal digital input. The

sensor is connected to digital input 18.

An external device is also controlled via control word bit

11 and the built-in relay of the frequency converter.

Reversing is allowed only when the reversing bit 15 in the

control word and the digital input 19 are set to high.

For safety reasons, the frequency converter stops the

motor if:

•

The PROFIBUS cable is broken.

•

The master has a system failure.

•

The PLC is in stop mode.

Probus master

Probus

Relay 04-05

230 V AC

Ext. device

Sensor

Reversing

6362

18

20

19

0-24 V DC

130BA087.10

Illustration 7.1 Wiring Diagram

Application Examples

VLT

®

PROFIBUS DP MCA 101

48 Danfoss A/S © 01/2016 All rights reserved. MG37G202

77

Loading...

Loading...