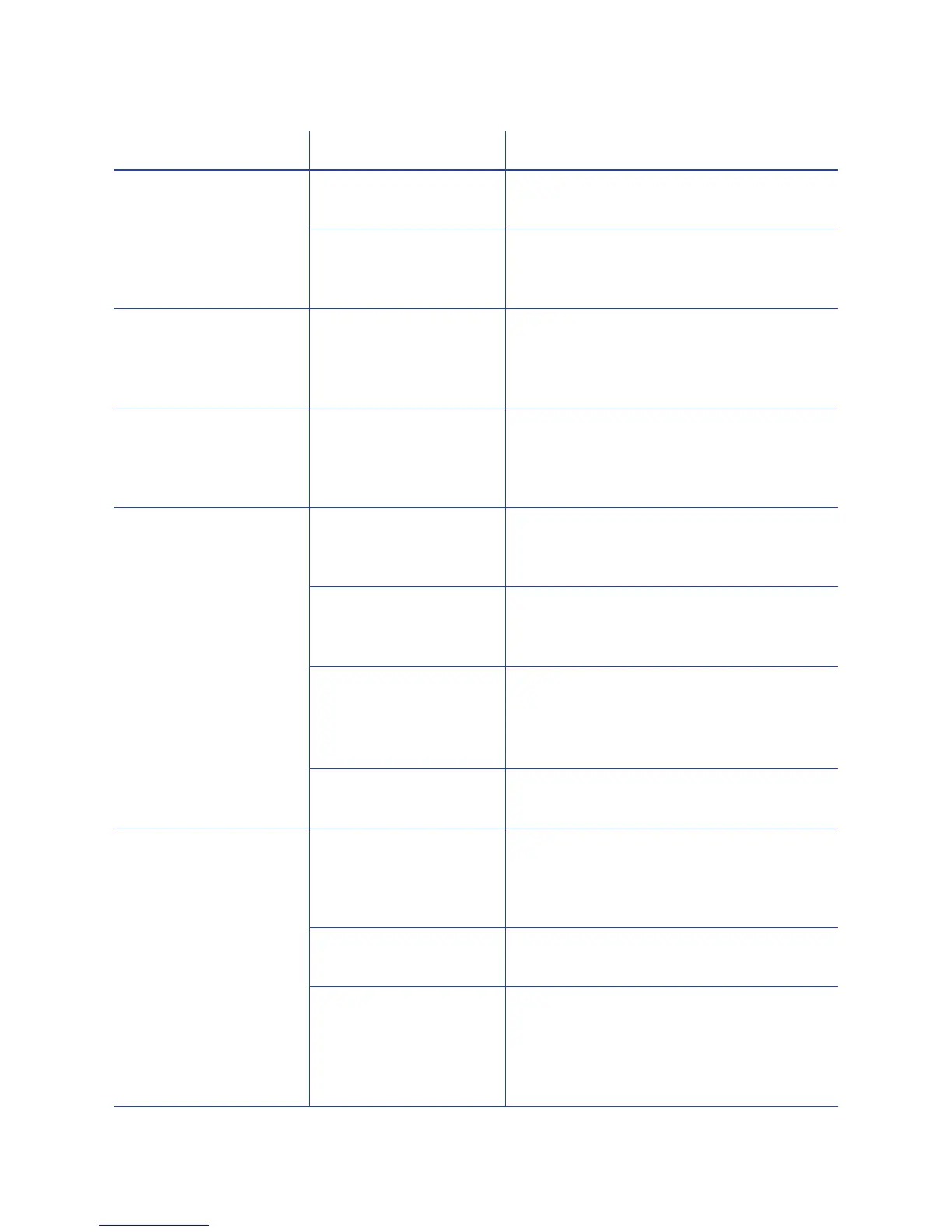

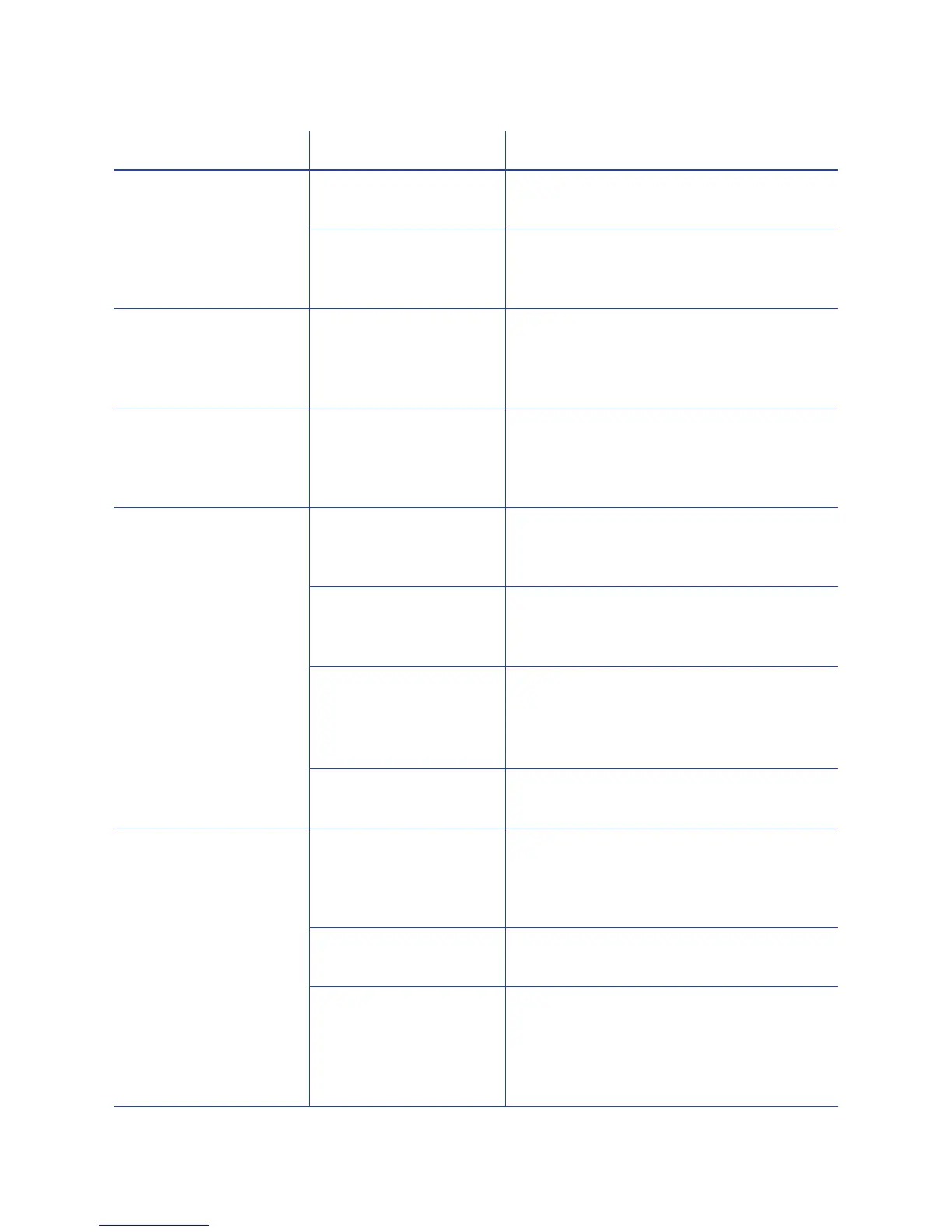

50 Troubleshooting

Therearescr atchesor

particlesunderthepatch.

Theinsideoftheprinter

isdirty.

Cleantheprinter.Referto“RunaPrinter

CleaningCard”onpage 30.

Thesupplieshavedebris

onthem.

Storeandhandlesuppliescarefully.Keep

suppliesintheoriginalpackaginguntilyou

arereadytousethem.

Thereare

repeating

marksonthepatch.

Theheatedrollerisdirty. Cleanthelaminator.Referto“Cleanthe

Laminator”onpage A‐12.Iftheproblem

continuestooccur,contactyourservice

provider.

Thepatchdoesn’tadhere

tothetrailingedgeofthe

card.

Theoverlayiswound

incorrectlyonthetake‐

upspool.

Process

anothercardtoallowtheoverlay

materialtoresetitself.Ifitdoesn’t,remove

thecartridgeandturnthetake‐upspool

clockwiseseveralturns.

Thepatchisnotcentered

betweenthelongedges

ofthecard.

Theoverlayisnotloaded

correctlyinthecartridge.

Loadtheoverlaymaterialcorrectly.Refer

to

“LoadLaminatorOverlayMaterial”on

page A‐8.

Thelaminatorcartridgeis

notfullyseatedinthe

laminator.

Makesurethatthecartridgeisseatedinthe

laminatorproperly.

Theoverlaymaterialis

woundunevenlyonthe

supplyroll.

Processseveralcardstoallowtheoverlay

materialtocenteritself.

Alignthe

edgesoftheoverlayonthetake‐up

spool.

Thelaminatorcartridgeis

damaged.

Replacethelaminatorcartridge.

Thepatchhaswavylines

alongthelengthofthe

card.

Thetemperaturefor

applyingtheoverlayis

settoohigh.

Decreasethelaminatortemperaturesetting.

RefertothePrinterManager“Laminate

Type”sectionof

theprinter’sInstallationand

Administrator ’sGuide.

Theheatedrolleris

damaged.

Powerdownthesystem.Contactyourservice

providerforassistance.

Thecardhasfeatures,

suchasasmartcardchip,

thatinterferewith

applicationofthe

overlay.

Usethecorrectpatchmaterialforyourcard

type.Referto“LaminatorOverlay Materials”

onpage A‐6foradescriptionofoverlay

types.

Problem ProbableCause Solution

Loading...

Loading...