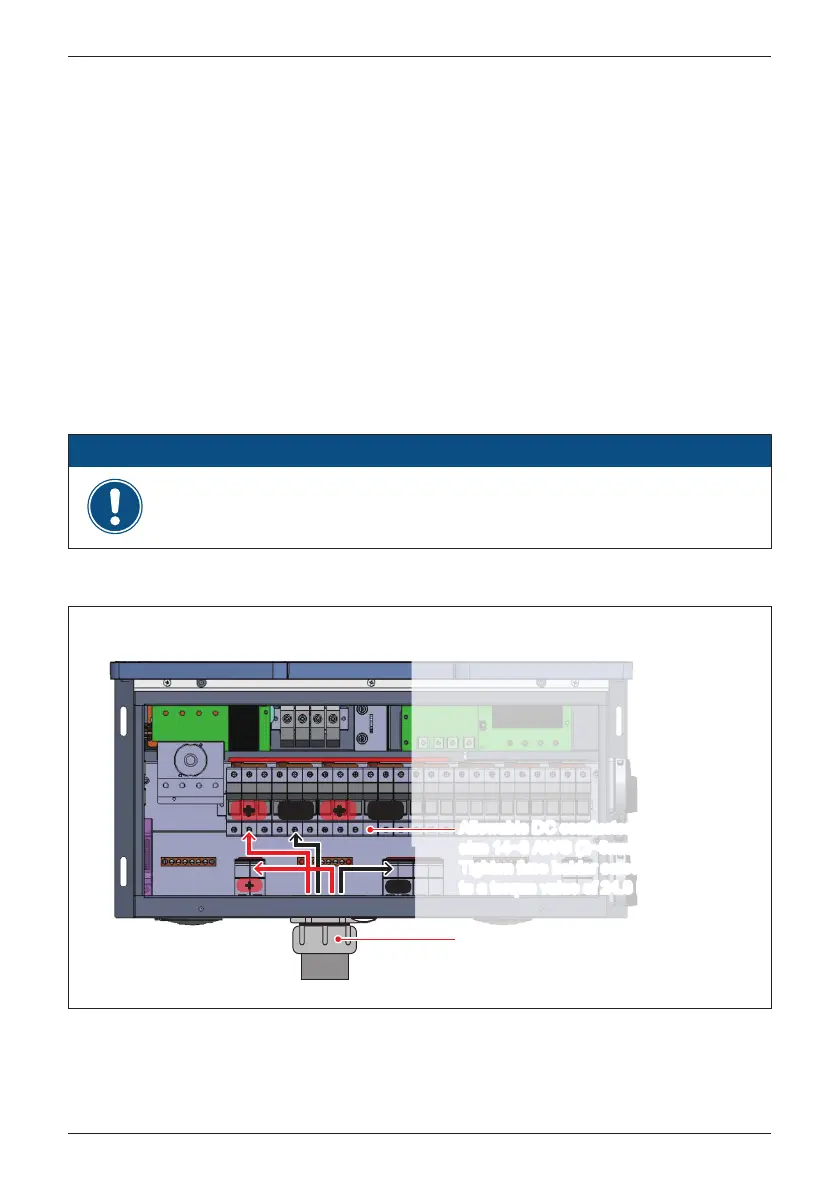

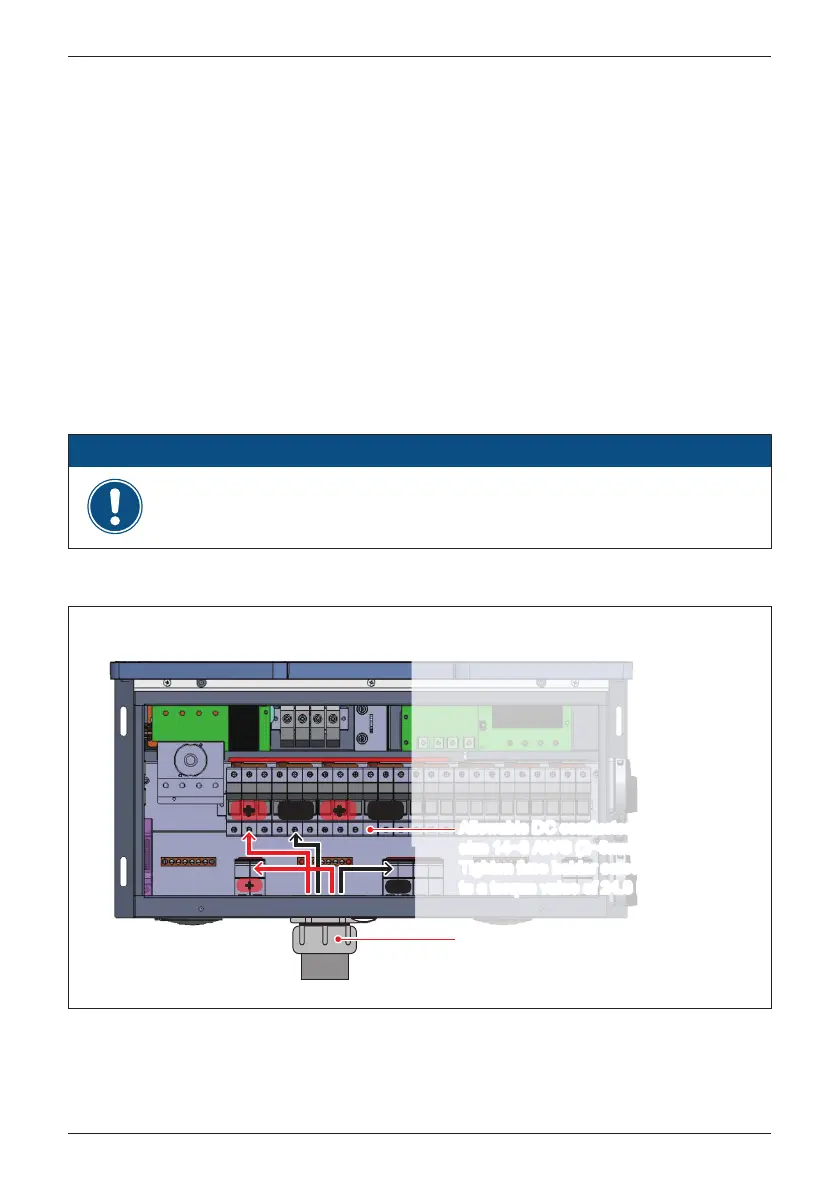

Figure 3-24: Location and string wiring to DC fuse holders for M80/60U_120

(shown for MPPT 1)

--

--

++

++

--

++

M80/60U_120

EMT

2” trade size chassis access,

1 per MPPT, 2 pl total,

for connection of DC conduits

Allowable DC conductor

size 14~8 AWG (2~8mm

2

)

Tighten fuse holder screws

to a torque value of 24.8 lbf-in (2.8 N•m)

Allowable DC conductor

size 14~8 AWG (2~8mm

2

)

Tighten fuse holder screws

to a torque value of 24.8 lbf-in (2.8 N•m)

- Ensure all fuse holder terminals are tightened to the specified torque value of

24.8 lbf-in (2.8 N•m).

ATTENTION

• Ensure the DC conductors used are Cu and sized to the correct ampacity per

NEC or other local code

• Strip off all wires for 14 mm [0.55in].

• The cross-sectional area for each DC conductor is 14~8 AWG.

• Ensure the fuse holder terminal clamp is open

• Ensure correct conductor is connected to the correct fuse holder.

• Tighten each individual screw terminal screw to a torque value of 24.8 lbf-in

(2.8 N•m).

• Two 2” chassis access holes (KOs), one per MPPT can be utilized to connect

conduits from PV array DC wiring into the inverter, as shown in Figure 3-24.

Please read the following instructions for connecting DC terminals (M80/60U_120) :

3.4.1 DC Wiring Installation for M80/60U_120 models

48

Installation

Loading...

Loading...