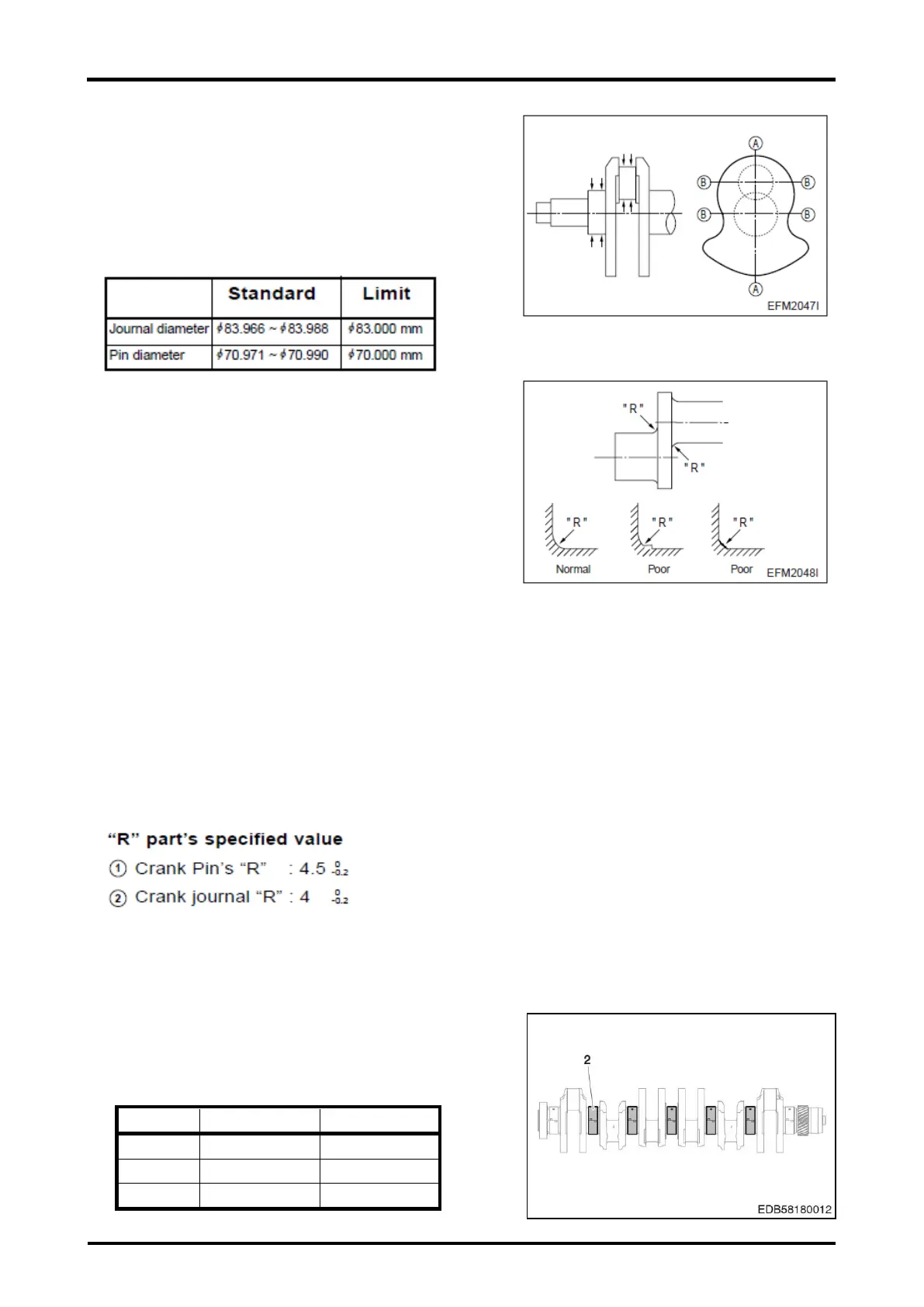

·If the amount of wear is beyond the limit, have the

crankshaft ground and install undersize bearings.

However, if the amount of wear is within the limit, you

can correct the wear using an oil stone or oiled

grinding paper of fine grain size. (Be sure to use

grinding paper which has been immersed in oil.)

·In case that pin’s wear is more than the limit value,

grind the crankshaft journal and crank pin, and use the

undersized bearings.

CAUTION:

Be sure to use grinding paper which

has been immersed in oil.

<Undersize bearings available>

·Standard

·0.25 (Inside diameter is 0.25 mm lesser than the standard size.)

·0.50 (Inside diameter is 0.50 mm lesser than the standard size.)

·0.75 (Inside diameter is 0.75 mm lesser than the standard size.)

·1.00 (Inside diameter is 1.00 mm lesser than the standard size.)

Undersize bearings are available in 4 different sizes as indicated above, and the crankshaft can be reused

through the regrinding as described above.

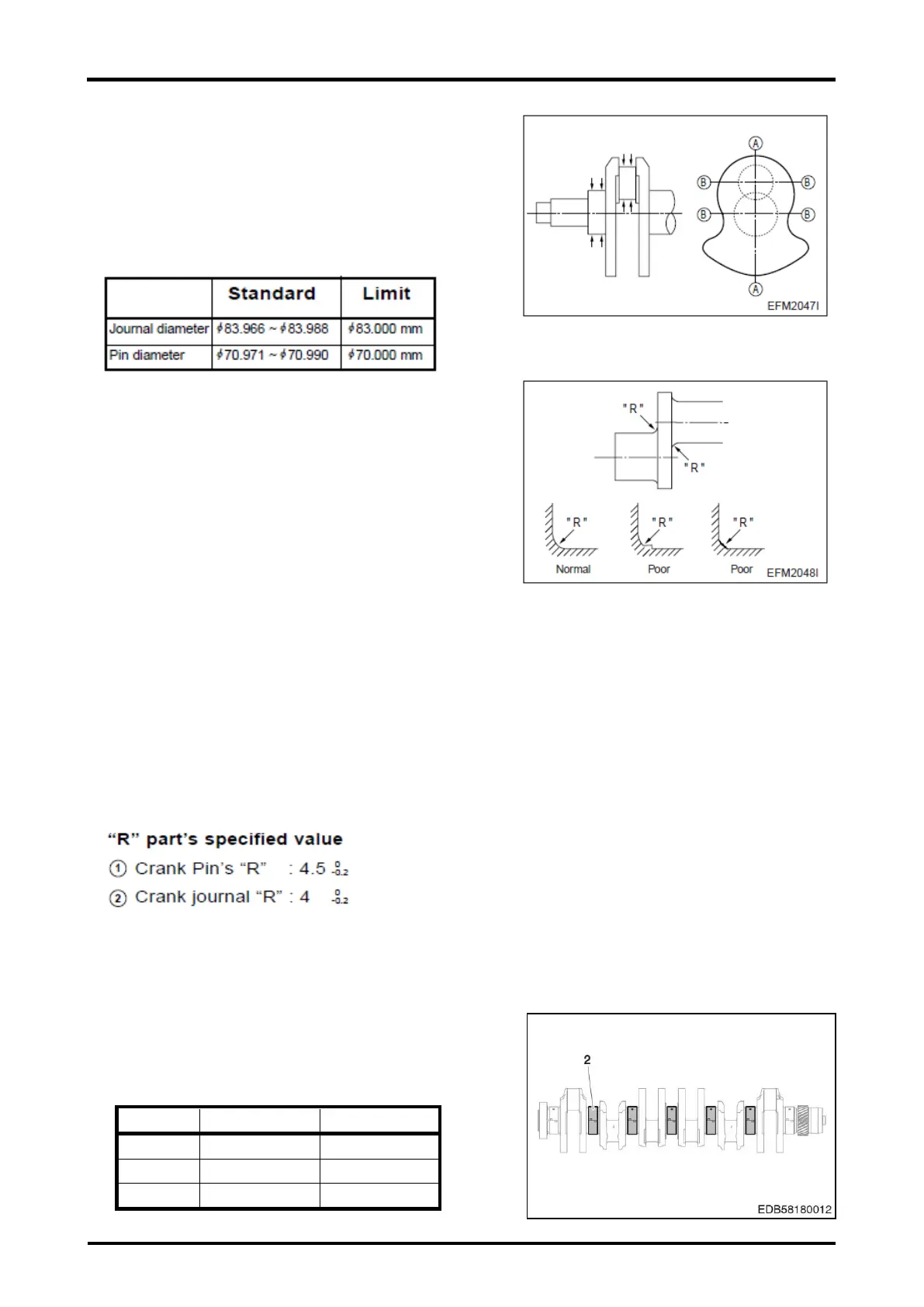

Caution:

In case of regrinding, the grinding the “R” part of bearing end should be correctly done and keep

in mind to remove any jaws or coarse surface absolutely.

(3) Crankshaft run-out

·Support the crankshaft on V blocks.

·Turn the crankshaft with a dial indicator placed on the

surface plate and take the amount of crankshaft run-out.

Loading...

Loading...