DL06K Interim Tire-4 Diesel Engine Maintenance of Major Components

195

z Checking the air cleaner cartridge

- Before reinstalling the cartridge, it

must be checked for damage e.g. to

the paper pleats and rubber gaskets,

or for bulges and dents etc. in the

metal jacket.

- Damaged cartridges should not be

reused under any circumstances. In

cases of doubt, discard the cartridge

and install a new one.

5.5. Belt

The tension of the belts should be checked after every 2,000 hours of operation.

(1) Change the belts if necessary

If in the case of a multiple belt drive, wear or differing tensions are found, always

replace the complete set of belts.

(2) Testing by hand

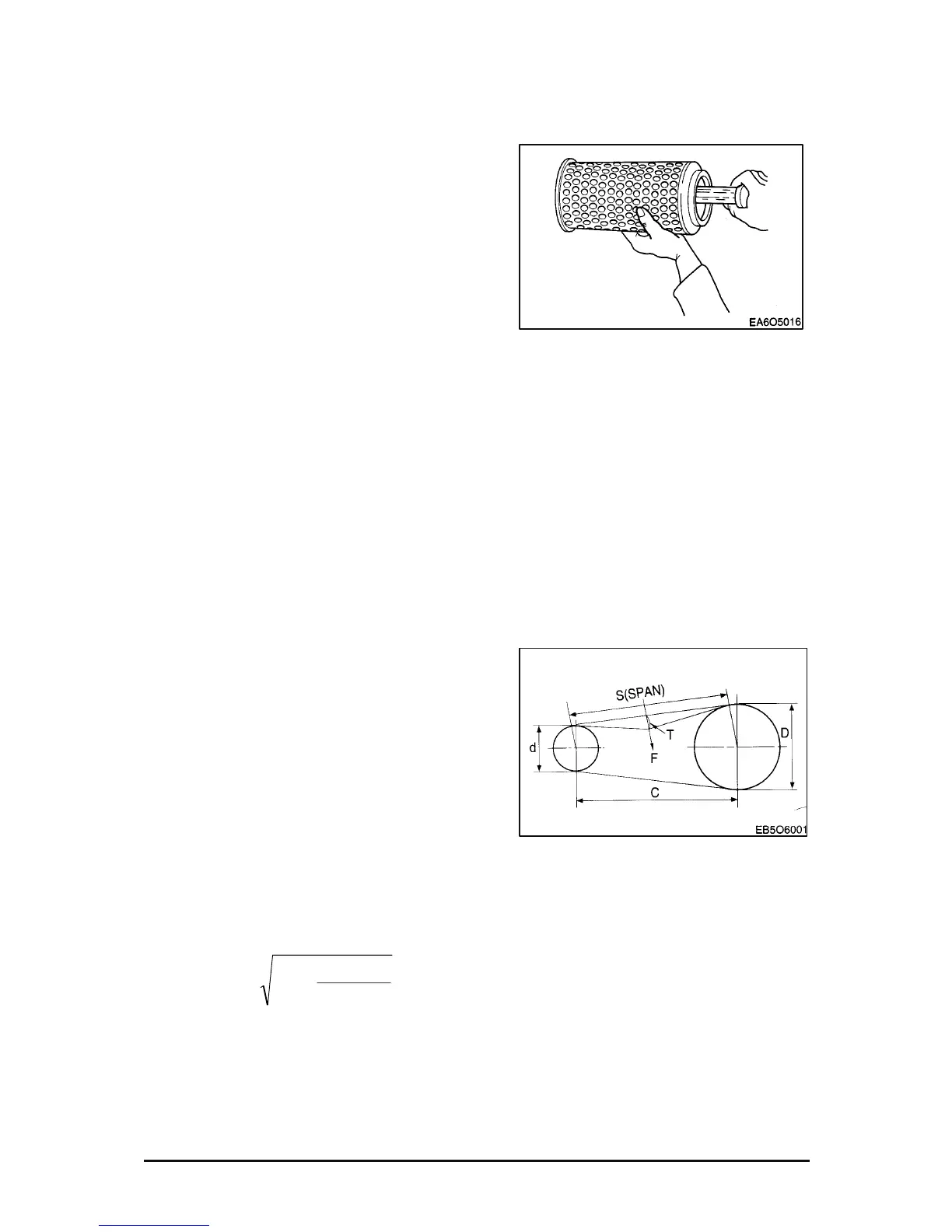

z Poly belt

Poly belt will be properly tensioned

if the deflection force “F” is applied

mid-way between the belt’s

tangent points with the pulley.

(T) = 0.015 x S (about 1.5mm per

100mm).

T = 0.015 x *S (mm)

(T : Deflection, S : Span)

*

C : Distance of pulleys (mm)

D : Large pulley diameter (mm)

d : Small pulley diameter (mm)

2

)(

2

2

dD

CS

−

−=

(mm)

Loading...

Loading...