DL06K Interim Tire-4 Diesel Engine Technical Information

53

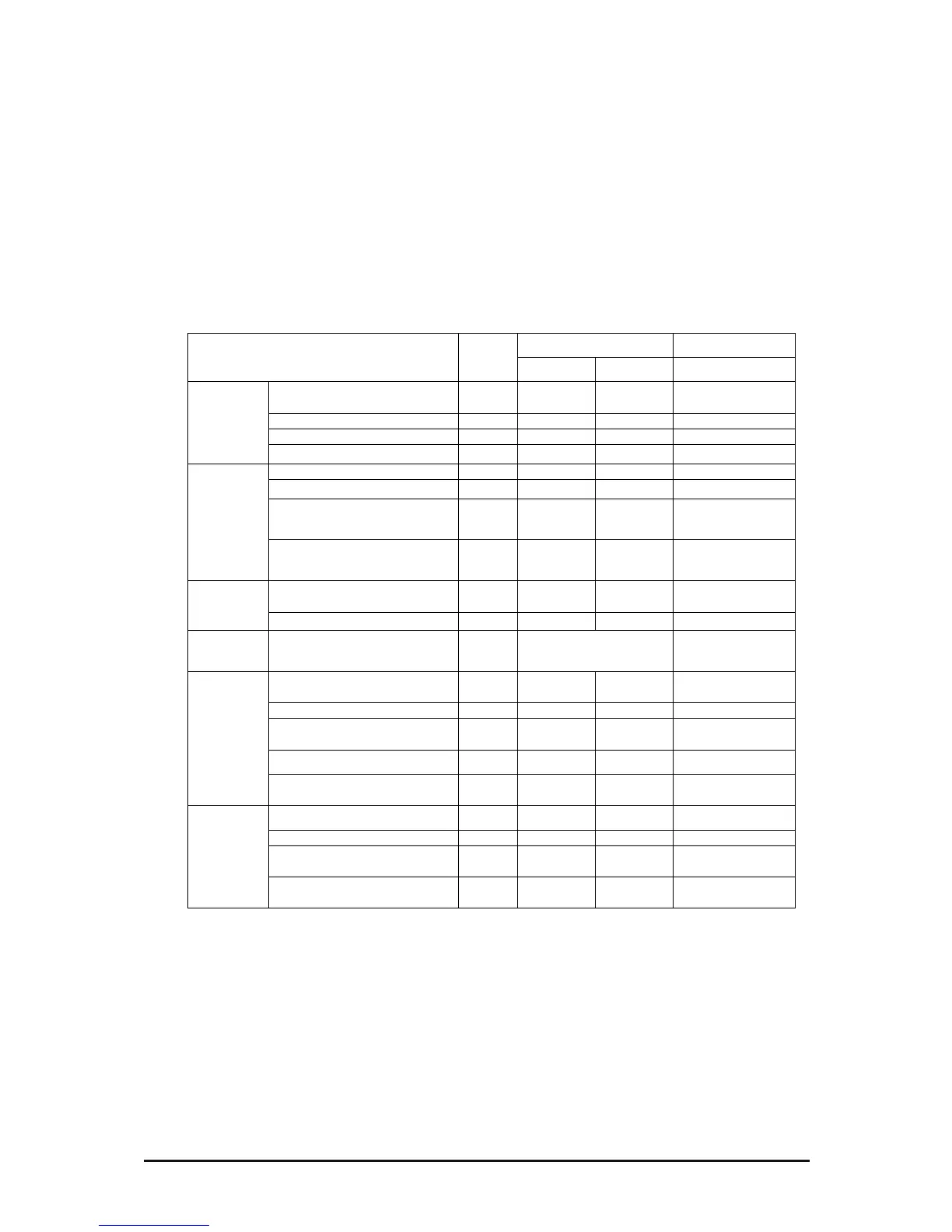

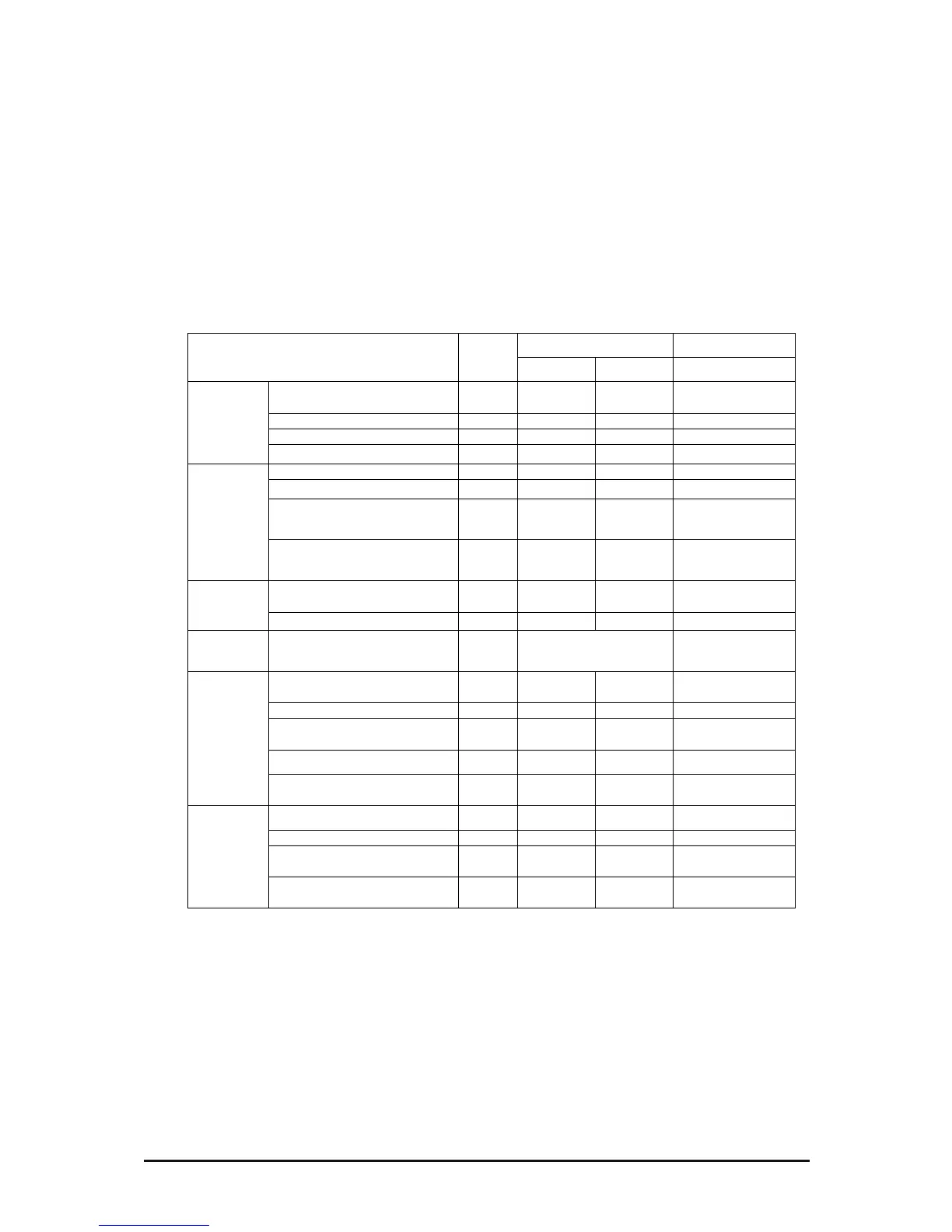

2.5. Engine Inspection

2.5.1. Regular check and maintenance

Regular check and maintenance are required to keep the best engine performance and

prevent malfunction.

– The following items should be checked everyday.

– The following items should be maintained regularly and thoroughly.

– This checklist is subject to the operation conditions of the vehicle.

О : Check & adjust ● : Replace

Inspection Daily

Inspection time (Hr)

Remark

50 500

Cooling

system

Check for leakage

(hoses, clamp)

О

Check the water level О

Check the V-belt tension О

Change the coolant water О

Lubrication

system

Check for leakage О

Check the oil level gauge О

Change the lubricating oil

●

1st

●

(Note1)

After the first

50 hours, replace

every 500 hours

Replace the oil filter cartridge

●

1st

●

(Note1)

After the first

50 hours, replace

every 500 hours

Intake

System

Inter cooler connection part

(hose, clamp)

О

Air filter pressure indicator О

Exhaust

system

DPF cleaning (Ash cleaning)

After the first 4,500

hours, clean every

3,000 hours (Note2)

Fuel

system

Extract moisture from oil/water

separator

О

Oil leak from the fuel line О

Fuel injection timing

When

necessary

Oil filter cartridge replacement

●

Check the injector

When

necessary

Engine

adjust

Check the exhaust gas state О

Check the battery charging О

Check the compression

pressure

When

necessary

Adjust intake/exhaust valve

clearance

When

necessary

* Note1 : Oil and cartridge replacement is subject to the use conditions.

* Note2 : Subject to the operating conditions, surroundings, or engine oil.

2.5.2. Use of original parts for repair and replacement

The engine is assembled by numerous parts and those parts are harmonized

mechanically. Therefore, engine failure can be prevented and the best performance

can be maintained only when the standard part recommended by the engine

manufacturer is used for replacement or repair during regular maintenance.

Loading...

Loading...