DL06K Interim Tire-4 Diesel Engine Disassembly and Reassembly of Major Components

90

3.3. Engine Reassembly

3.3.1. General precautions

z Clean all the disassembled parts, particularly oil and water ports, using

compressed air, then check that they are free from restrictions.

z Arrange the general and special tools in order for engine assembly operation.

z To wet each sliding part, prepare the clean engine oil.

z Prepare service materials such as sealant, gaskets, etc.

z Discard used gaskets, seal rings, and consumable parts, and replace with new ones.

z Apply only the specified torque for bolts in the specified tightening order and

avoid over-tightening.

z Be sure to check that all the engine parts operate smoothly after being reassembled.

z Check the bolts for looseness after reassembly.

z After completing the engine reassembly operation, check if there is missing parts

or shortage of parts.

z Keep your hands clean during the working.

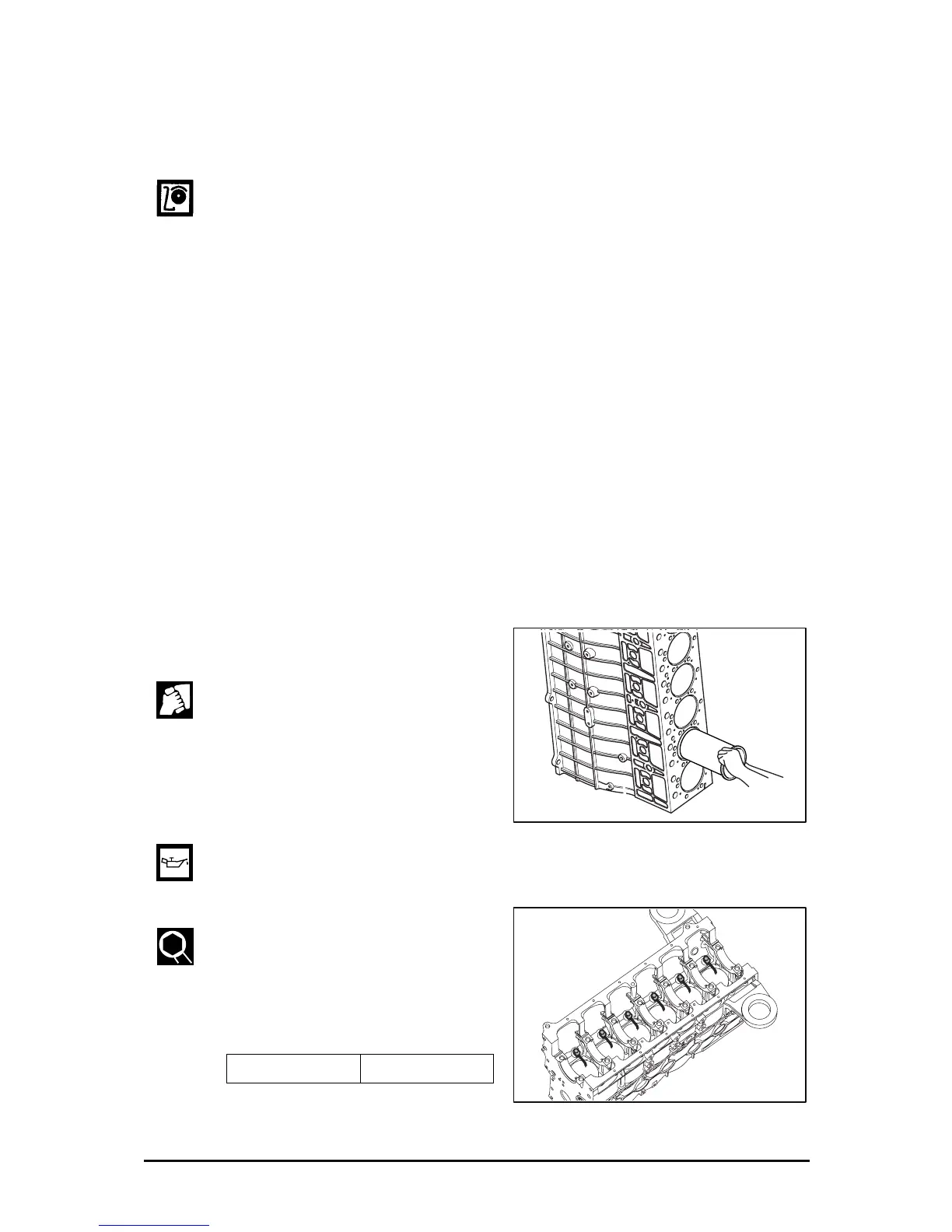

3.3.2. Cylinder block

z Put wood or thick paper on the workplace floor and face the head assembly

surface downward, so that the cylinder head assembly surface is not damaged.

3.3.3. Cylinder liner

z Stand the cylinder block so that the

flywheel faces downward.

z Thoroughly clean the liner flange

fitting surface and bore inside with

compressed air to prevent the entry of

foreign substances.

z After the cleaning operation, make the

cylinder liner dried up and push it into

the cylinder block by hand.

z Wet the liner inside diameter with engine oil.

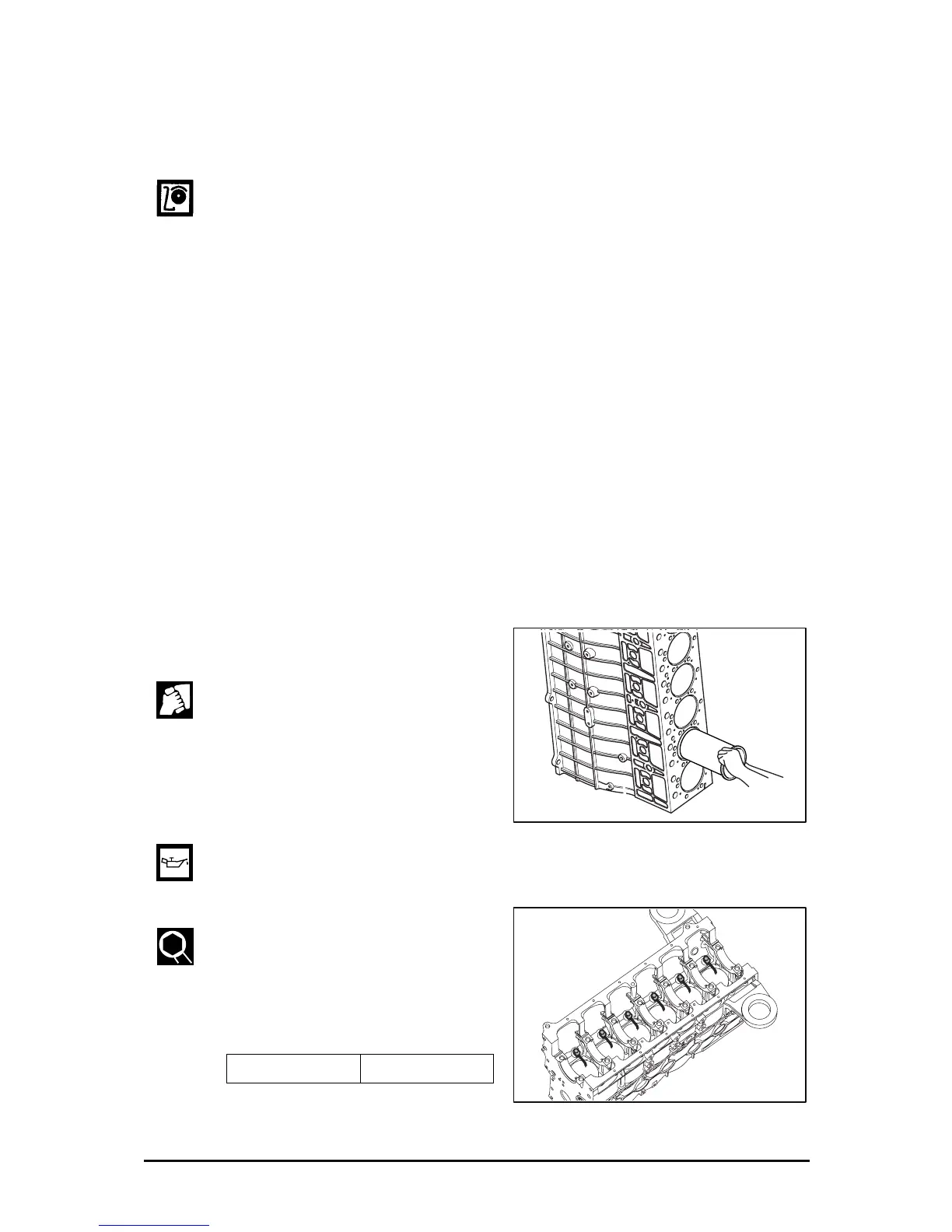

3.3.4. Oil spray nozzle

z Adjust the oil injection nozzle to the

cylinder block groove, using the oil

injection nozzle assembly jig, and

assemble them with relief valve fixing

bolts.

Torque 2.1 kgf•m

EE1OM061

EK4OM065

Loading...

Loading...