27

GB

Explosion-protected, light alloy Ex-d (e) control stations and

distributions, Series: GHG 64

In accordance with the approvals, the Ex-d

control stations can also be built together on a

building block principle to form distributions

using separately certified Ex-e busbar or

connection boxes of the type GHG 75. They

are mounted on wall or free-standing frames.

The electrical connection is made using

flameproof cable bushings.

The connection cables are fed into busbar or

connection boxes via cable entries in the type

of protection Increased Safety.

The minimum clearances and creepage

distances up to 10 KV in accordance with

EN/IEC 60079-7, Table 7, shall be observed.

Warning: The maximum dimensions of

the distribution must not exceed

2,18 m x 6,30m.

Applications other than those described

are not permissible without a written

declaration of consent from Messrs.

Cooper Crouse-Hinds / EATON.

The sole responsibility with respect to the

suitability and proper use of these boxes lies

with the operator.

CCH assumes no liability for damage arising

from improper use.

6 Installation

The relevant national regulations (e.g. BetriSiV,

the equipment safety law for Germany) and the

generally recognized rules of engineering apply

for the installation and operation

(IEC/EN 60079-14).

Only fully certified apparatus may be

installed and put into operation.

a The improper installation and operation

of enclosures can result in the invalidation

of the guarantee.

6.1 Mounting of Ex-d control station and

distributions

The Ex-d control station and distributions can

be mounted without opening the enclosure´s

cover. The enclosures are intended for wall

or floor mounting. When enclosures with an

optional hinge for the cover are mounted on

a wall, it is necessary to ensure that the cover

may only be swung open sideways.

The distances for flange joints of flameproof

equipment to any solid obstacles have to meet

the requirements of IEC/EN 60079-14. The

flange joint is located between the cover and

enclosure. Smaller distances than defined in

IEC/EN 60079-14 are covered by the

certification(s).

Cooper Crouse-Hinds GmbH reserves the right

using them in installations.

When the flameproof enclosures and distribu-

tions are mounted directly onto the wall or onto

wall or floor frames, they shall rest evenly

without twisting on the fastening points

provided for this purpose.

The screws and washers selected shall match

the fixing holes. The flameproof enclosure can

also be mounted using hook bolts or with

mounting brackets.

The mounting brackets can be fitted facing

upwards, downwards or sideways.

Suitable screws with a spring washer and

washer shall be used for screwing them onto

the enclosure. All the mounting brackets shall

be used when mounting the Ex-d enclosure.

The fixing dimensions can be found in the

Technical Data.

In order to mount the cover of the Ex-d

correctly, it is essential to ensure that there is

no twisting.

a Excessive tightening can damage the

flameproof enclosures.

6.2 Opening enclosure

Before opening the enclosures, it is

necessary to ensure that there is not

potentially explosive.

Before opening the enclosure, it is

necessary to ensure that the voltage

supply has been isolated or to take

suitable protective measures.

Before opening , Ex-d flameproof enclosure

with built-in load disconnect switch, set the

switch to the „ON“ position.

The enclosure cover is fixed to the enclosure

base using special screws

(up to enclosure size 7

M10 x 55,

from enclosure size 8 M10 x 65).

Enclosure without optional cover hinge:

- Loosen all screws

- After the cover screws have been loosened,

the cover can be removed by carefully sliding

it to the side.

Do not damage flameproof joints on the

enclosure cover and enclosure by making

scratches!

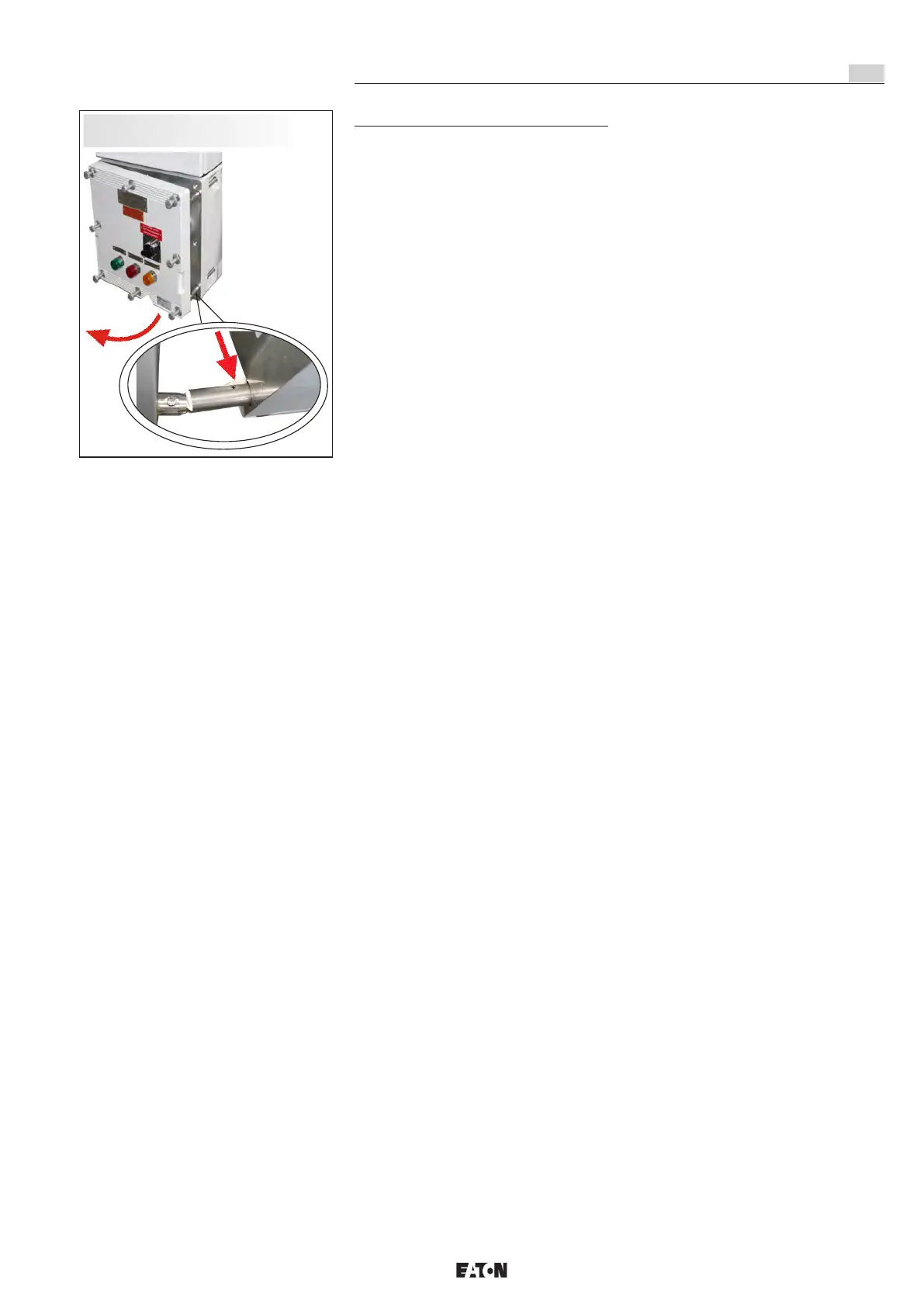

Enclosure with optional cover hinge

(Fig. 2)

After the cover screws (special screw) have

been loosened, a compression spring lifts

the enclosure cover off the enclosure body.

This allows the cover to be opened without

damaging the flameproof joint (flat joint).

The following procedure is recommended:

Loosen the cover screws and unscrew until

the screw threads barely engage in the cover.

Loosen the middle cover screw on the side of

the enclosure where the hinge is mounted last.

Do not open cover yet!

Pull out the enclosure cover on the side with

the hinge until the hinge catch disengages. This

prevents the enclosure cover from tipping to

one side. When opening the cover fully, care

shall be taken to ensure that restraining cord

does not get caught in the built-in components,

as this could damage them.

Do not put any unnecessary strain on the

hinge mechanism by opening the cover abruptly

or by placing any additional loads on the open

enclosure cover.

Fig. 2 Opening enclosure with

optional hing

Loading...

Loading...