© Edwards Limited 2010. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Operation

D397-50-880 Issue C

4.7.1 Software module 852 - DX Pump Control

General Description

Main DX Pump control and monitoring module. This module must be selected for pump control.

Output bytes (from Master)

Input bytes (to Master)

Associated Parameter options

None.

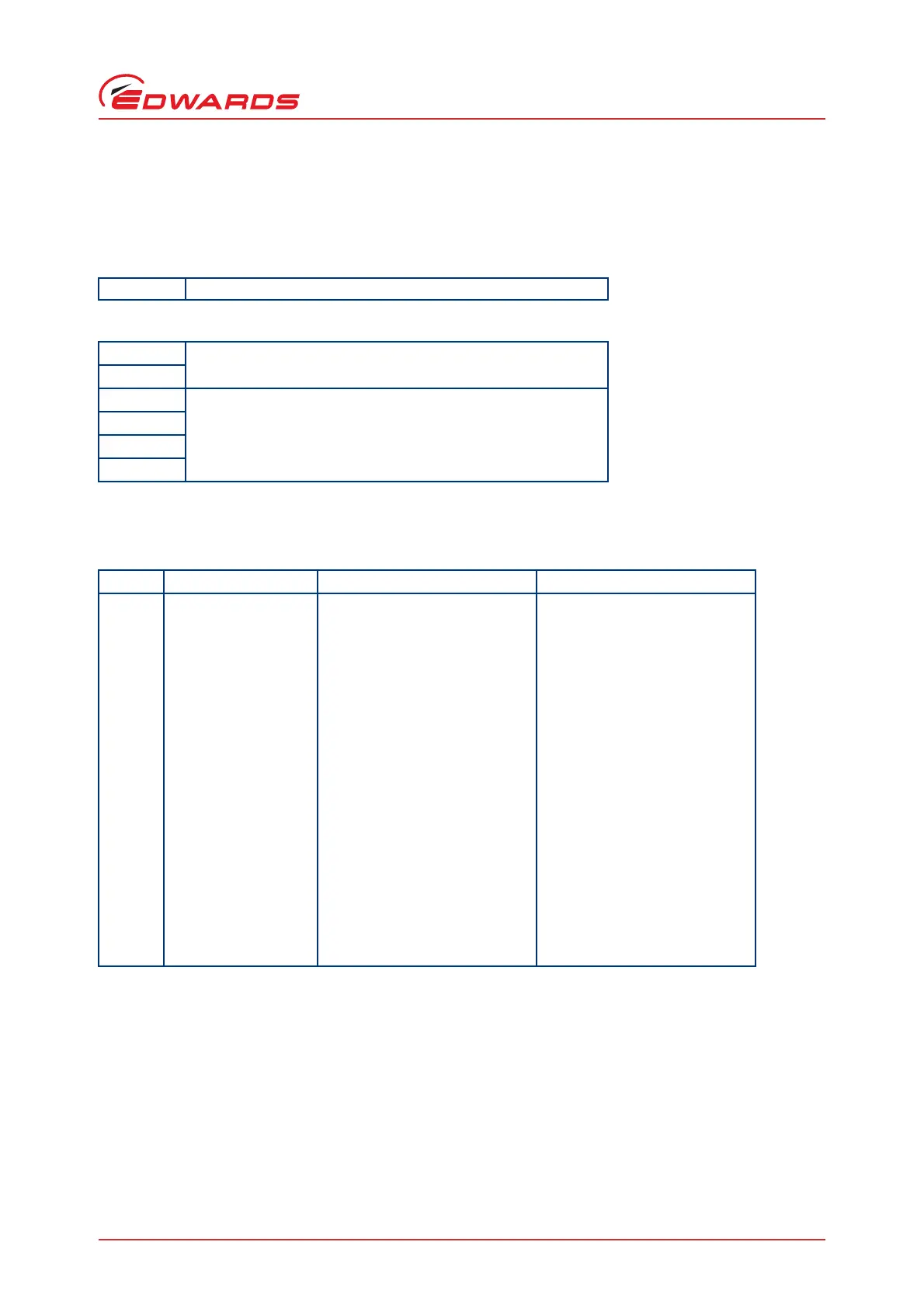

Table 15 - DX status flags

1st Stop if value 0. Run if value 1.

1st Form a 16-bit number, which is the motor speed in Revolutions per

Second. (0-1800).

2nd

3rd Form a 32-bit system status word. The Upper two bytes (3rd and

4th) are reserved. Each bit of lower 2 bytes is a flag. To decode

the status first convert the value to binary. Refer to

Ta b le 1 5 to interpret each bit.

4th

5th

6th

Bit No. Status Flag Name Meaning if Flag 0 Meaning if Flag 1

0 Fail Not failed Failure condition

1 Stopped Speed Pump in motion Pump at rest

2 Normal Speed Below normal speed Above normal speed

3 Vent valve Valve output not powered Valve output powered

4 Start Not commanded to start Commanded to start

5 Serial Enable Serial control disabled Serial control enabled

6 Standby Standby not commanded Standby commanded

7 50% speed Below 50% speed Above 50% speed

8 Parallel control Not in Parallel control mode In Parallel control mode

9 Serial control Not in Serial control mode In Serial control mode

10 Software Compatibility Podule software not mis-matched Invalid Podule software

11 Software Completion Podule upload complete Podule Config or Cal failed

12 Timer State Timer duration not exceeded Timer (for 50% speed) expired

13 Hardware Trip No trip Overspeed or Overcurrent trip

14 Thermistor Error Internal temp system good Internal temp system failed

15 Serial Interlock Serial enable good Serial enable bad

Loading...

Loading...