6 AGL_HA_ST_Discus_A2L_A1_EN_Rev00

2.5.4 Unloaded start

Ignition source in a potentially flammable atmosphere! Fire hazard! The

solenoid valve of the unloaded start is not an ignition source during normal

operation in an A2L-refrigerant system but could become one if not installed

properly. Never operate the solenoid coil when not positioned on the solenoid

valve. Secure the installation with a screw.

Unloaded start is mainly required for compressors connected for part-winding start (for example with

motor version AWM) or star-delta start (motor version EWM).

2.5.4.1 Unloaded start for 2D* and 3D* models

As a result of the compressor design of the 2D* and 3D* models, the components for unloaded start

are mounted outside the compressor housing. The unloaded start kit consists of a very short bypass

line that connects the high-pressure side of the compressor to the suction side. A solenoid valve is

installed in this bypass line.

When the compressor is switched on, the solenoid valve opens the bypass line and holds it open

during the starting phase. The refrigerant vapour is short-circuited without any significant increase in

pressure, and the motor is unloaded.

After completion of the starting procedure, ie, after energizing of the second part-winding or

changeover from star to delta or short-circuiting of starting resistors, the solenoid valve is de-

energized, closing off the bypass line.

A Non-Return Valve (NRV) must be installed in the discharge line to prevent the refrigerant from

flowing back from the condenser to the suction side.

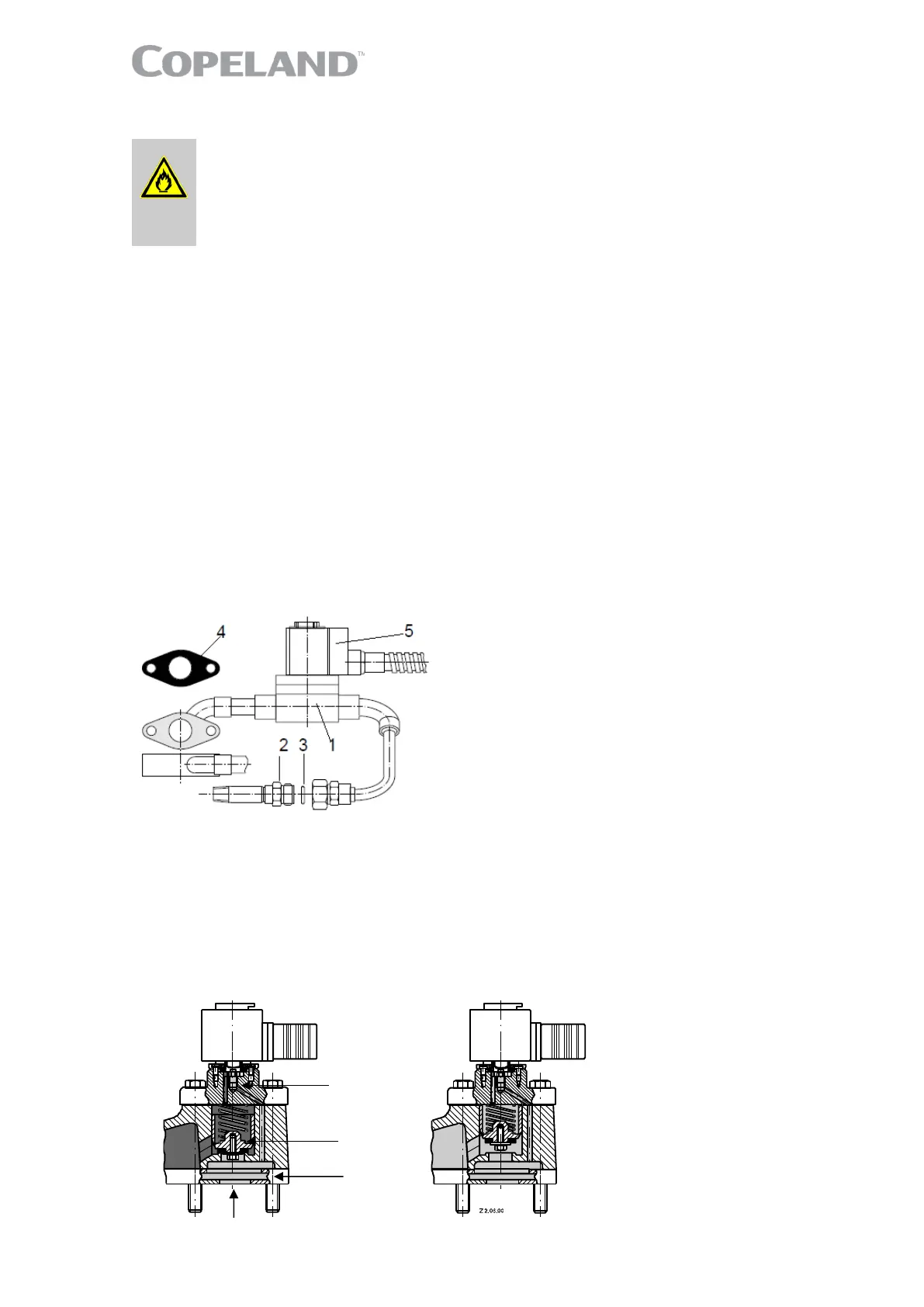

The kit consists of the following parts:

Figure 4: Unloaded start components for 2D* and 3D* models

2.5.4.2 Unloaded start for 8D* models

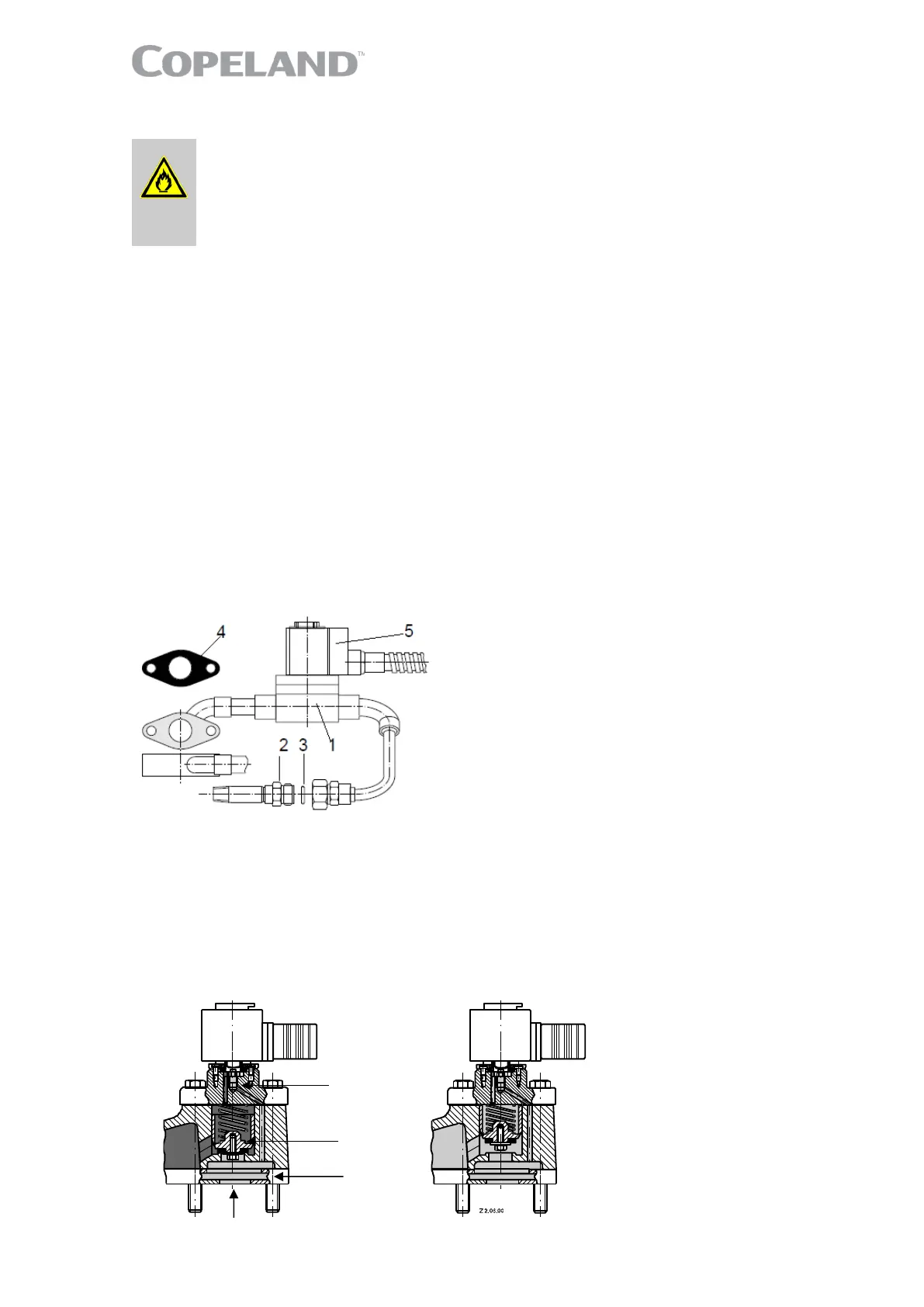

8D* compressors can be equipped with an internal unloaded start system, to be ordered as an option.

The compressor prepared for unloaded start is supplied with a special cylinder head. The control

valve and coil are positioned on the top of the cylinder head. An additional check valve must be

installed in the discharge piping. Recommended inbuild position for the check valve is approximately

50-100 cm to the compressor discharge connection.

A. Standard operation B. Unloaded start operation

Figure 5: Unloaded start components & operation for 8D* models

2 Solenoid

3 Valve

4 Spring-loaded control piston

5 Suction side

6 High side in the cylinder head

7 Valve plate

1 x Pipe assembly and valve body (1)

1 x Rotalock stub (2)

1 x Rotalock seal (3)

1 x Gasket - flange to cylinder head (4)

1 x Gasket - flange to Rotalock valve (4)

1 x Solenoid valve coil (5)

1 x Check valve

x Screws ½" – 13 UNC X 2¾"

Loading...

Loading...