AGL_HA_ST_Discus_A2L_A1_EN_Rev00 11

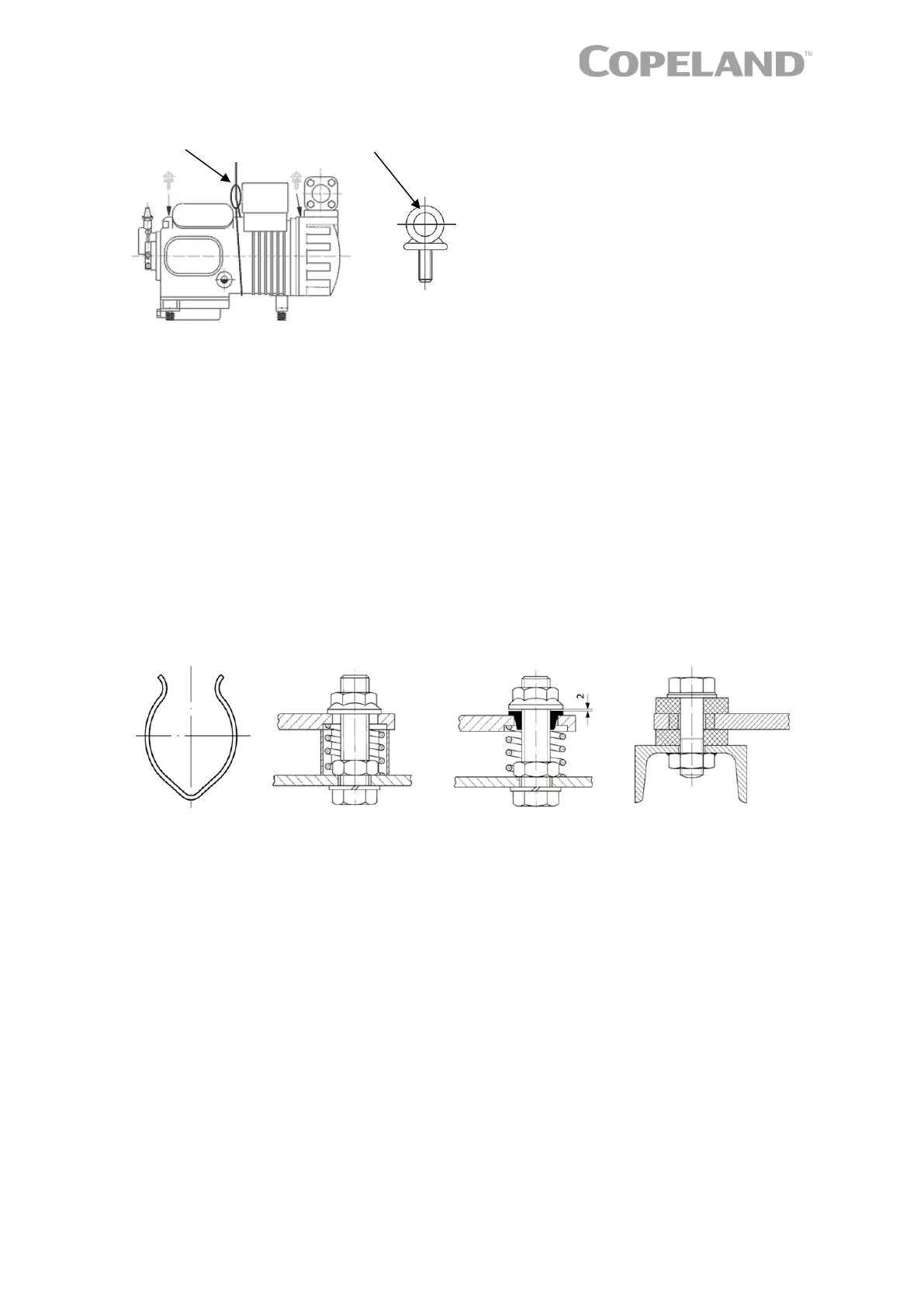

8D* Lifting eye

max. 350 kg ½" – 13 UNC

Figure 13: Compressor lifting methods

3.1.4 Installation location

Ensure the compressors are installed on a solid level base.

For multiple compressor parallel configurations, the compressors must be positioned completely

vertically on a totally horizontal surface or rail.

3.1.5 Mounting parts

To minimize vibration and start/stop impulses flexible mounting should be used. For this purpose one

specific set of spring mounting parts is delivered with each compressor model.

A compressor may be rigidly mounted, ie, without springs. In this case more shock and vibration

loading will be transmitted to the frame.

If the installation requires a very high level of vibration absorption, additional vibration absorbers –

available on the market – can be fitted between the rails and the foundation.

To ensure proper lubrication of moving parts, the compressor should be installed horizontally on both

axes.

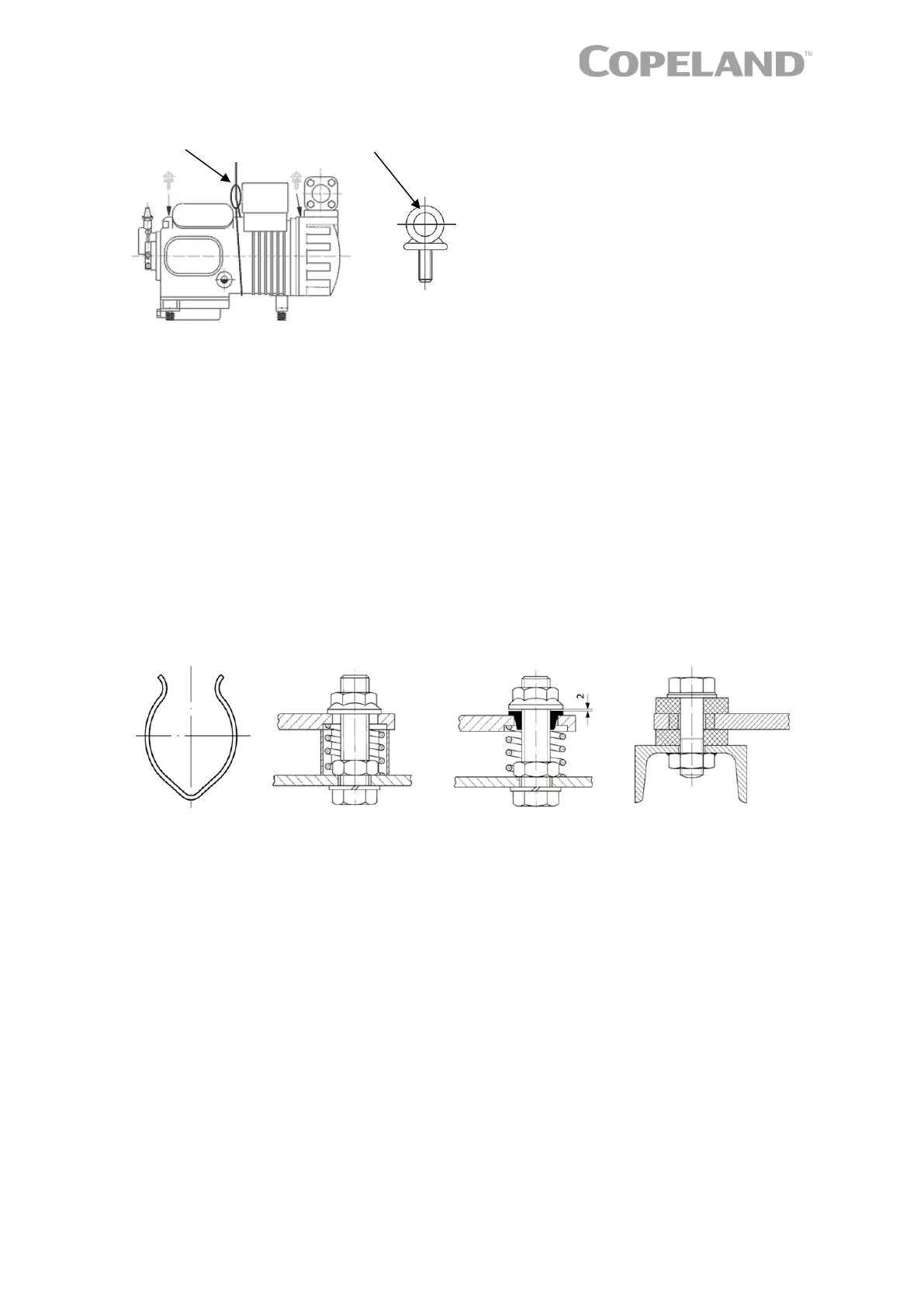

Transport clamp Transport position Operating position Grommets for twin

compressors

Figure 14: Position of vibration dampers during transport and operation

3.2 Pressure safety controls

3.2.1 High-pressure protection

Applicable regulations and standards, for example EN 378-2, shall be followed to apply appropriate

control and ensure that the pressure never exceeds the maximum limit.

High-pressure protection is required to stop the compressor operating outside the allowable pressure

limits. The high-pressure control must be installed correctly, which means that no service valve is

allowed between the compressor and the pressure protection.

The high-pressure cut-out setting shall be determined according to the applicable standard, the type

of system, the refrigerant and the maximum allowable pressure PS.

The high-pressure cut-out should have a manual reset feature for the highest level of system

protection.

Loading...

Loading...