AGL_HA_ST_Discus_A2L_A1_EN_Rev00 7

Usually, the unloaded start is activated once for about 5-10 seconds shortly before compressor start

and then kept closed during operation. The unloaded start solenoid valve opens a suction channel

in the valve plate and the pressure in the discharge line equalizes to the suction side.

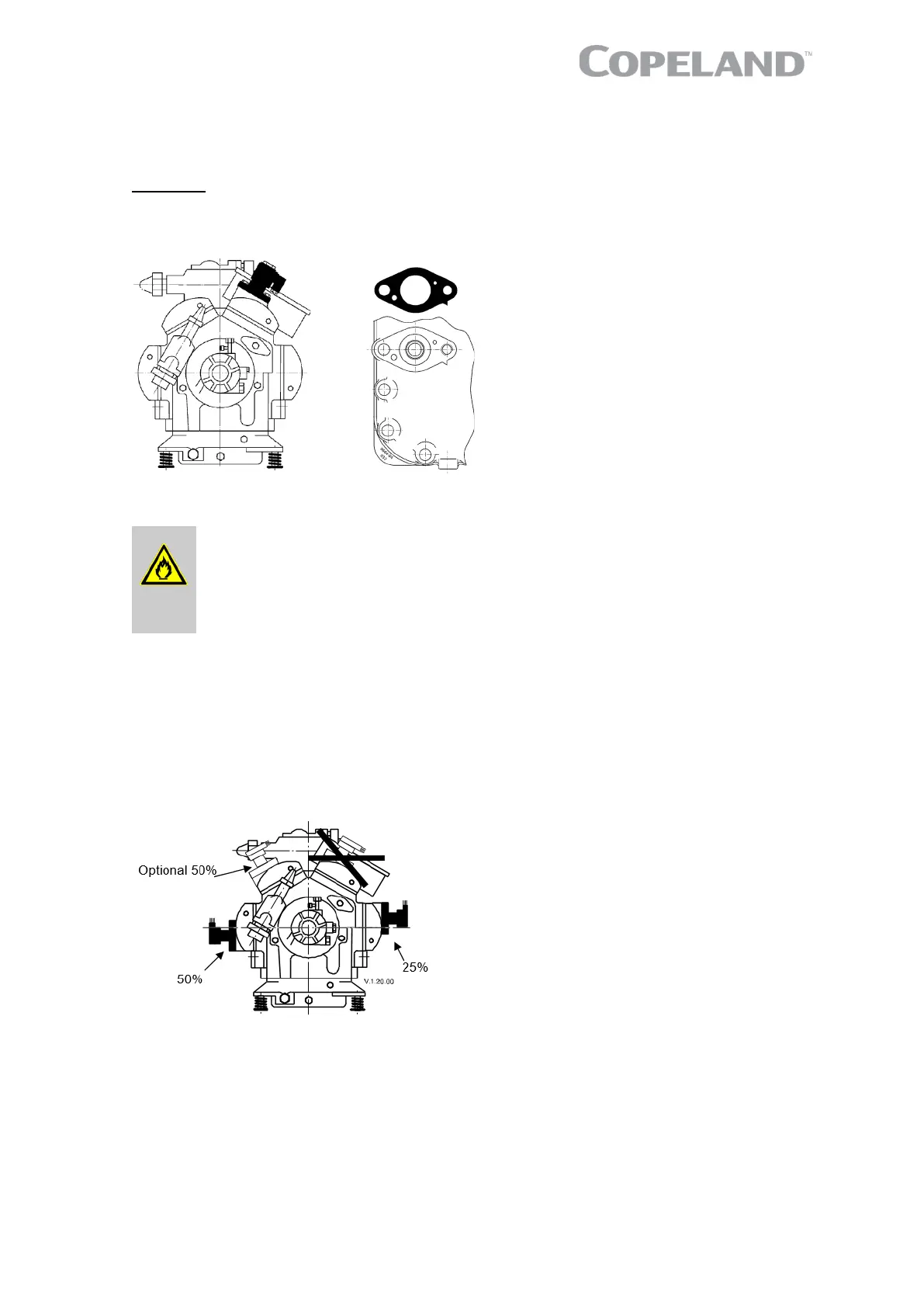

Assembly

Installation of the modified cylinder head and valve plate for unloaded start is only possible at certain

positions on the compressor. Therefore all 8D* compressor models have fixed cylinder head

positions for unloaded start.

Figure 6: Unloaded start position for 8D* models

2.5.5 Capacity control

Ignition source in a potentially flammable atmosphere! Fire hazard! The

solenoid valve of the capacity control is not an ignition source during normal

operation in an A2L-refrigerant system but could become one if not installed

properly. Never operate the solenoid coil when not positioned on the solenoid

valve. Secure the installation with a screw.

A mechanical capacity control is available for 8D* compressors. The system used is blocked suction.

The suction port of the valve plate will be closed by a control piston. When an 8D* compressor is

ordered with capacity control, it is equipped with one or two special cylinder heads. The capacity

control valves with coils are positioned on the top of the cylinder head. Not all cylinder bank positions

are possible for the capacity control cylinder head.

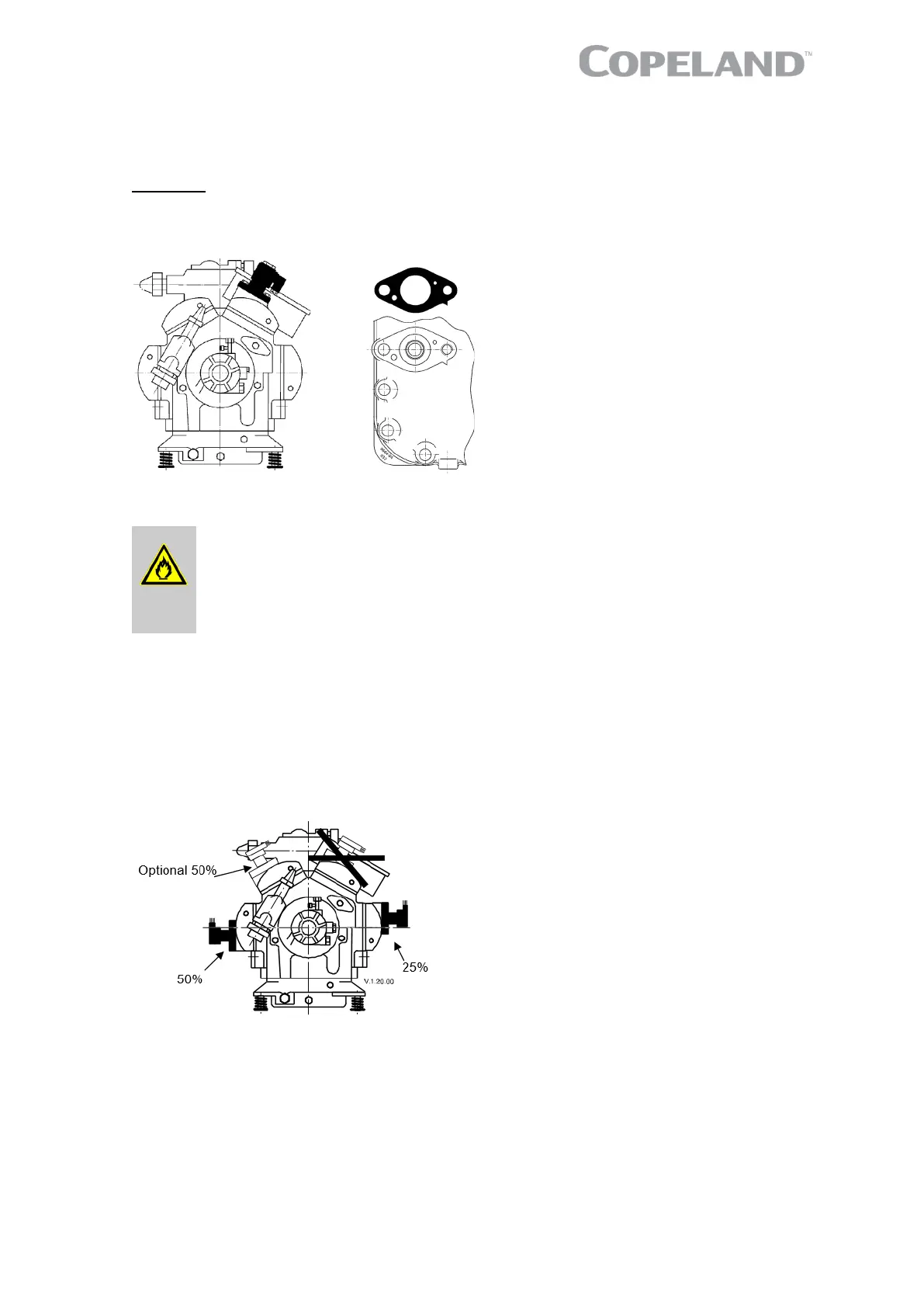

Capacity control must be fitted in the following positions:

8D* 1

st

step 25 % Lower cylinder head on terminal box side

8D* 2

nd

step 50 % Lower cylinder head on discharge valve side

Figure 7: Capacity control position on 8D* models

2.5.6 Oil pump

All 2D*, 3D* and 8D* compressors are equipped with an external oil pump. The oil pump will always

work in the correct direction of rotation, regardless of the rotation direction of the compressor. The

compressors are designed to accommodate fittings for an OPS2 oil safety system (OPS2 oil sensor

included in the oil pump) or any conventional oil pressure switch.

2.5.7 Oil pressure

Normal oil pressure is between 1 and 4.2 bar higher than crankcase pressure. Net oil pressure can

be read by connecting two pressure gauges to the compressor and comparing the readings. One

Loading...

Loading...