Safety and operating instructions

© Construction Tools GmbH | 3390 5149 01 | 2020-09-22

Original Instructions

25

NOTICE Damage due to incorrect oil pressure setting

Incorrect oil pressure setting can result in severe dam-

age to property and the environment.

u Before installing the hydraulic attachment to the car-

rier check the oil pressure setting of pressure line

»P« with a hydraulic flow tester.

u Check the tank/return line pressure with an additional

manometer mounted between hydraulic flow tester

and tank line »T«.

u Ensure the technical specifications are fulfilled (see

chapter Technical specifications).

5.4.3 Install separate leakage oil line

The separate leakage oil line including separate leakage

oil filter must be installed from the shut-off valve on the

boom to the carrier's hydraulic oil tank. The operator

must pre-install a suitable connection on the carrier's hy-

draulic oil tank for the leakage oil line.

NOTICE Damage due to incorrect installed hydraulic

hoses

Incorrectly installed hydraulic hoses can result in severe

damage to property and the environment. The maximum

pressure of the leakage oil line is 10bar.

u Install hydraulic hoses such that they always pos-

sess sufficient play for turning and rotating motions

of the boom.

u Always check the leakage oil line pressure when

mounting the hydraulic attachment to a carrier.

n

Install a separate leakage oil line along the hydraulic

hoses on the boom and secure with cable ties.

n

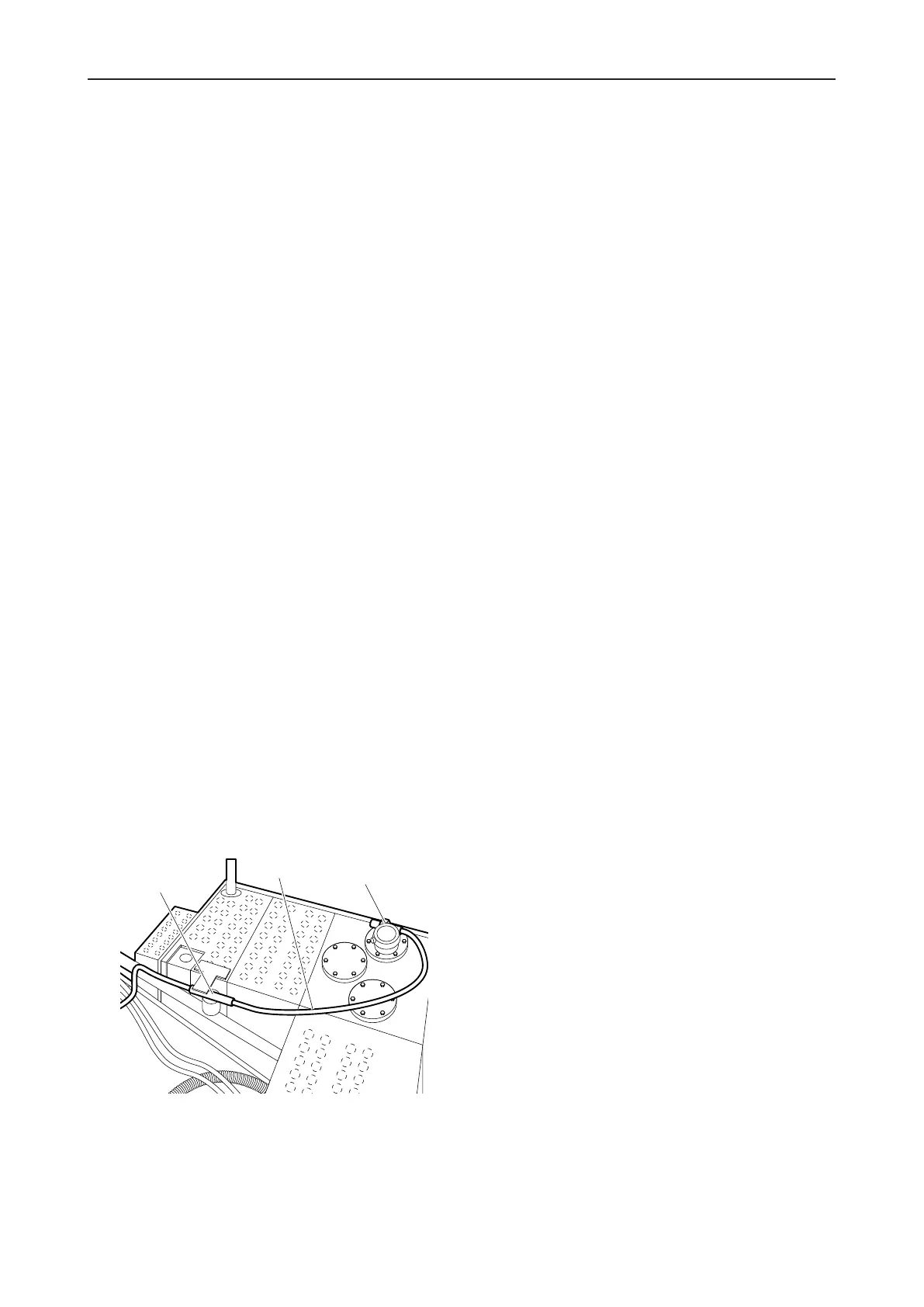

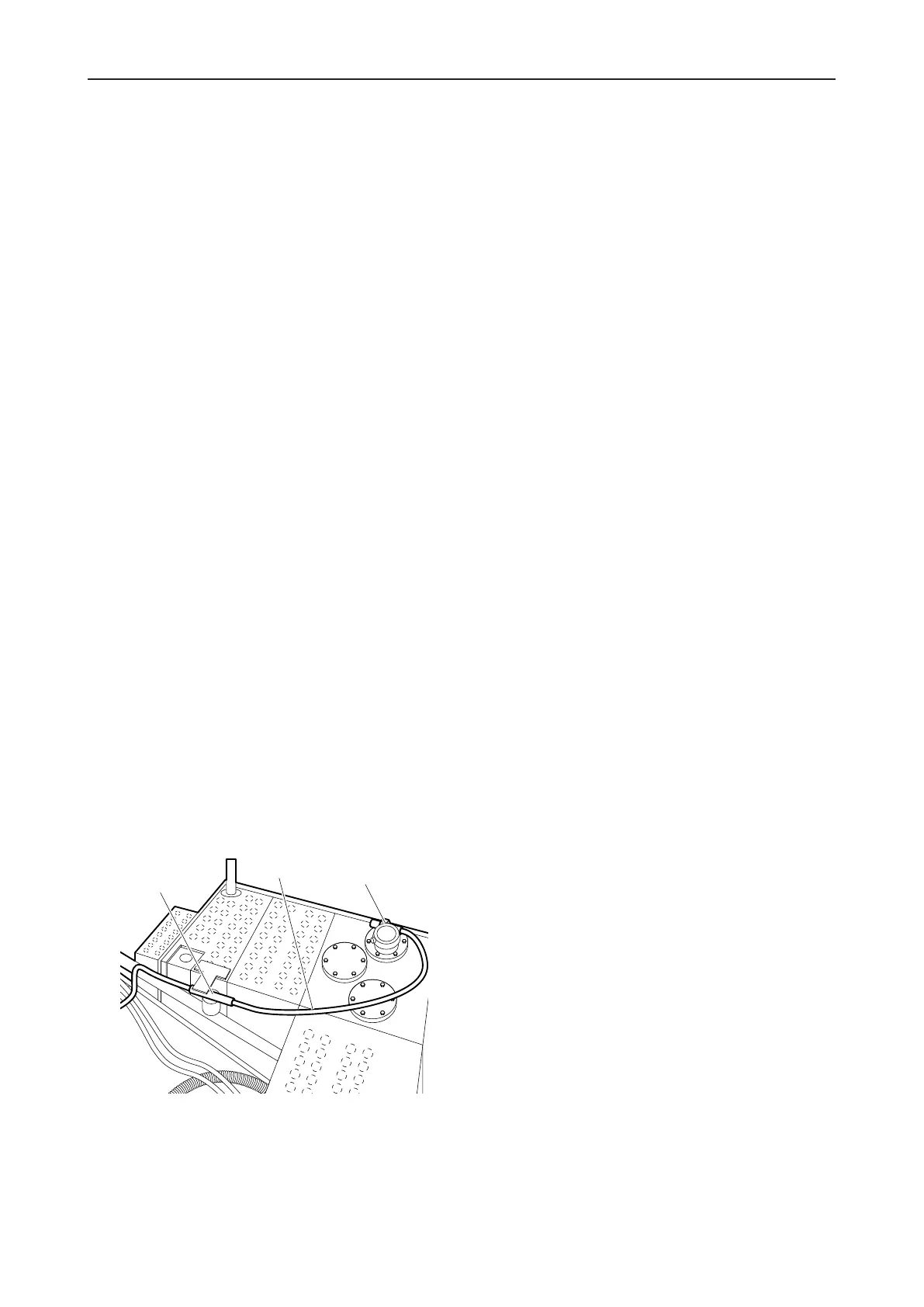

Install the separate leakage oil line(J) with leakage

oil filter(I) to the connection on the carrier's hydraulic

oil tank(K).

Follow the safety and operating instructions of the

carrier when connecting the leakage oil line to the hy-

draulic oil tank.

n

Attach the leakage oil line to the pre-installed connec-

tion on the hydraulic oil tank and tighten with the re-

quired tightening torque.

n

Install the leakage oil filter at an appropriate location

on the carrier.

5.4.4 Making the hydraulic connections

NOTICE Faulty hydraulic installation

The carrier must have a suitable hydraulic installation to

operate the hydraulic attachment. Improperly installed

lines and incorrectly rated sizes may cause the oil to

heat up and the hydraulic attachment to be damaged.

u Only use hydraulic lines of the rated sizes as in-

structed (see chapter Technical Specifications).

u Check the rated size of the hydraulic lines on existing

hydraulic installations! All supply and return lines for

the hydraulic oil must have a sufficient inside diame-

ter and wall thickness.

u Route all hydraulic hoses in a torsion-free manner.

n

Switch off the carrier.

n

Depressurise the hydraulic system by releasing the

carrier's hydraulic tank pressure.

n

Close all shut-off valves in the installation at the

boom, if no quick couplings are used.

NOTICE Damage to hydraulic parts

Polluted hydraulic lines and connections may enable

sand, fragments of material and dirt to penetrate the hy-

draulic attachment and damage the hydraulic parts.

u Clean the hydraulic lines and connections prior to

connecting the hydraulic lines.

n

Have dirty hydraulic lines rinsed through by a special-

ist company.

n

Clean dirty hydraulic line connections with a suitable

grease-dissolving universal cleaner.

n

Observe the cleaner manufacturer's information on

safety and use.

n

Connect the hoses of the pressure line »P«, the tank

line »T« and the hose for the function »magnet plate

on/off« at the boom.

n

Remove the screw caps from the connections »A«,

»F« and »G« of the Hydro Magnet and keep them in

a safe place.

Loading...

Loading...