Adjustment Work

Adjustment work comprises 3 types of adjustments that

are done in order.

Preparation

Use the following to do adjustment work.

Adjustment Film Sheet (3 sheet)

Use the ones distributed during User Self Repair

training.

M size platen

Use one that has no grip pad on it.

Execute Print Head

Alignment

A

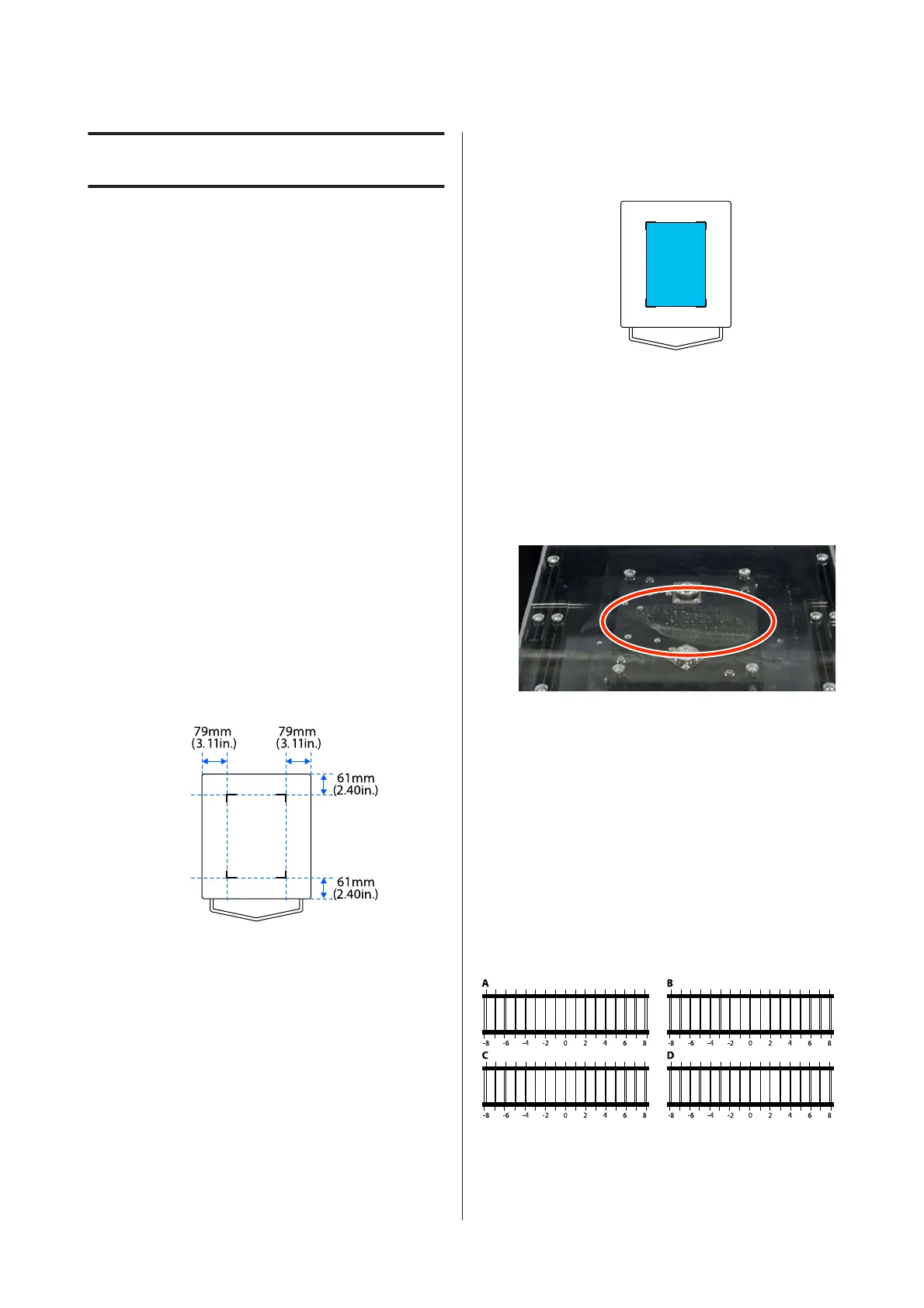

Mark guidelines for the position on the platen to

set the film, as shown in the illustration.

B

Use a sprayer to spray water on the center of the

platen.

If you do not dampen the surface of the platen

with water, you cannot correctly set the

Adjustment Film Sheet.

C

Starting from the front of the platen, slide a new

Adjustment Film Sheet along the surface of the

platen so it aligns with the marks as you place it.

Be sure to align the film with the markings. If it is

placed in a different position, the platen may be

soiled with ink.

D

Be sure that the film adheres correctly.

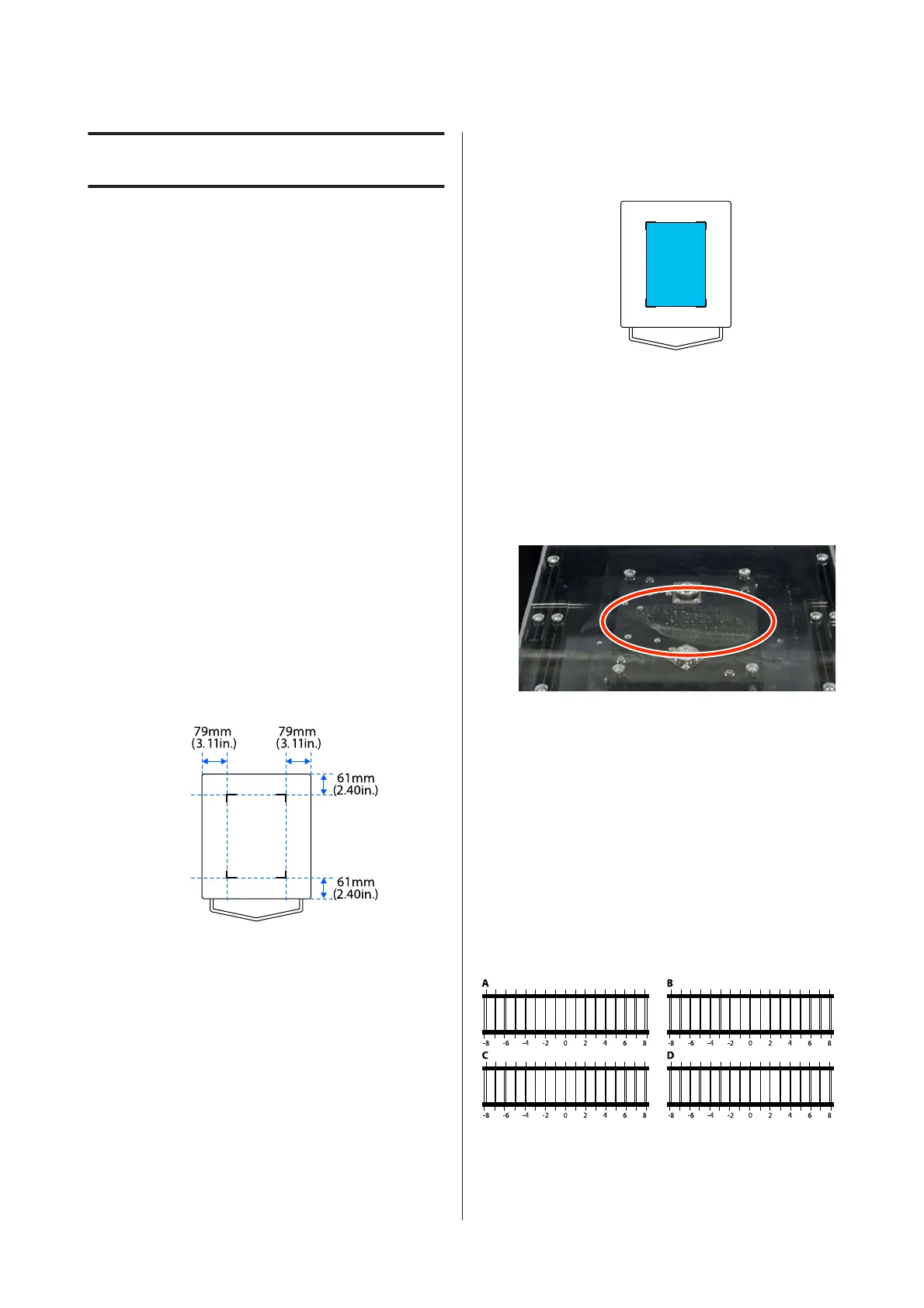

❏ If there is air between the film and the platen, as

shown in the illustration, return to step 3 and

reset it.

❏ If there is any water on the surface of the film,

use a soft cloth that is not likely to generate lint

to wipe it off.

E

Press Start.

Pressing the x button starts printing the

adjustment pattern. When printing the pattern is

complete, the adjustment value entry screen is

displayed. Continue to the next procedure.

F

Check the printed adjustment pattern.

Check the 4 patterns A to D, and select from -8 to

+8, where the line appears thinnest (lines

overlap) in the pattern.

SC-F3000 Series How to Replace the Print Head

Adjustment Work

23

Loading...

Loading...