01-9

Basic Engine

01-9

OVERHAUL (Continued)

Under no circumstances should the faces of aluminized

intake valves be ground or the valves lapped in as this will

remove the diffused aluminum coating and reduce the

valves’ wear and heat resistant properties. If the valve

faces are worn or pitted it will be necessary to install new

valves and to resurface the valve seats or, alternatively, lap

the seats using dummy valves. The exhaust valves may be

lapped in or the faces ground if required.

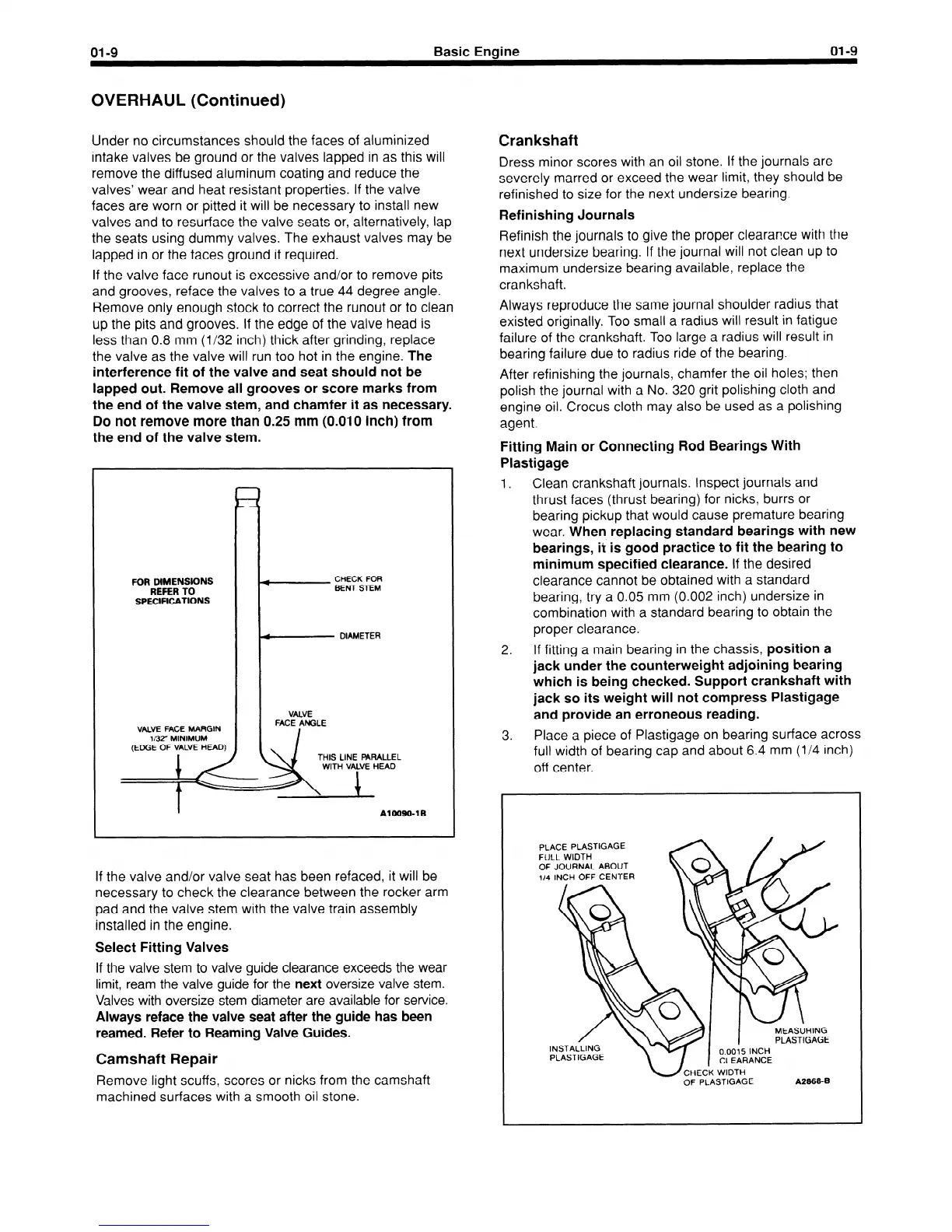

If the valve face runout is excessive and/or to remove pits

and grooves, reface the valves to a true 44 degree angle.

Remove only enough stock to correct the runout or to clean

up the pits and grooves. If the edge of the valve head is

less than 0.8 mm (l/32 inch) thick after grinding, replace

the valve as the valve will run too hot in the engine.

The

interference fit of the valve and seat should not be

lapped out. Remove all grooves or score marks from

the end of the valve stem, and chamfer it as necessary.

Do not remove more than 0.25 mm (0.010 inch) from

the end of the valve stem.

FOR DIMENSIONS

REFER TO

SPECIFICATIONS

If the valve and/or valve seat has been refaced, it will be

necessary to check the clearance between the rocker arm

pad and the valve stem with the valve train assembly

installed in the engine.

Select Fitting Valves

If the valve stem to valve guide clearance exceeds the wear

limit, ream the valve guide for the

next

oversize valve stem.

Valves with oversize stem diameter are available for service.

Always reface the valve seat after the guide has been

reamed. Refer to Reaming Valve Guides.

Camshaft Repair

Remove light scuffs, scores or nicks from the camshaft

machined surfaces with a smooth oil stone.

Crankshaft

Dress minor scores with an oil stone. If the journals are

severely marred or exceed the wear limit, they should be

refinished to size for the next undersize bearing.

Refinishing Journals

Refinish the journals to give the proper clearance with the

next undersize bearing. If the journal will not clean up to

maximum undersize bearing available, replace the

crankshaft.

Always reproduce the same journal shoulder radius that

existed originally. Too small a radius will result in fatigue

failure of the crankshaft. Too large a radius will result in

bearing failure due to radius ride of the bearing.

After refinishing the journals, chamfer the oil holes; then

polish the journal with a No. 320 grit polishing cloth and

engine oil. Crocus cloth may also be used as a polishing

agent.

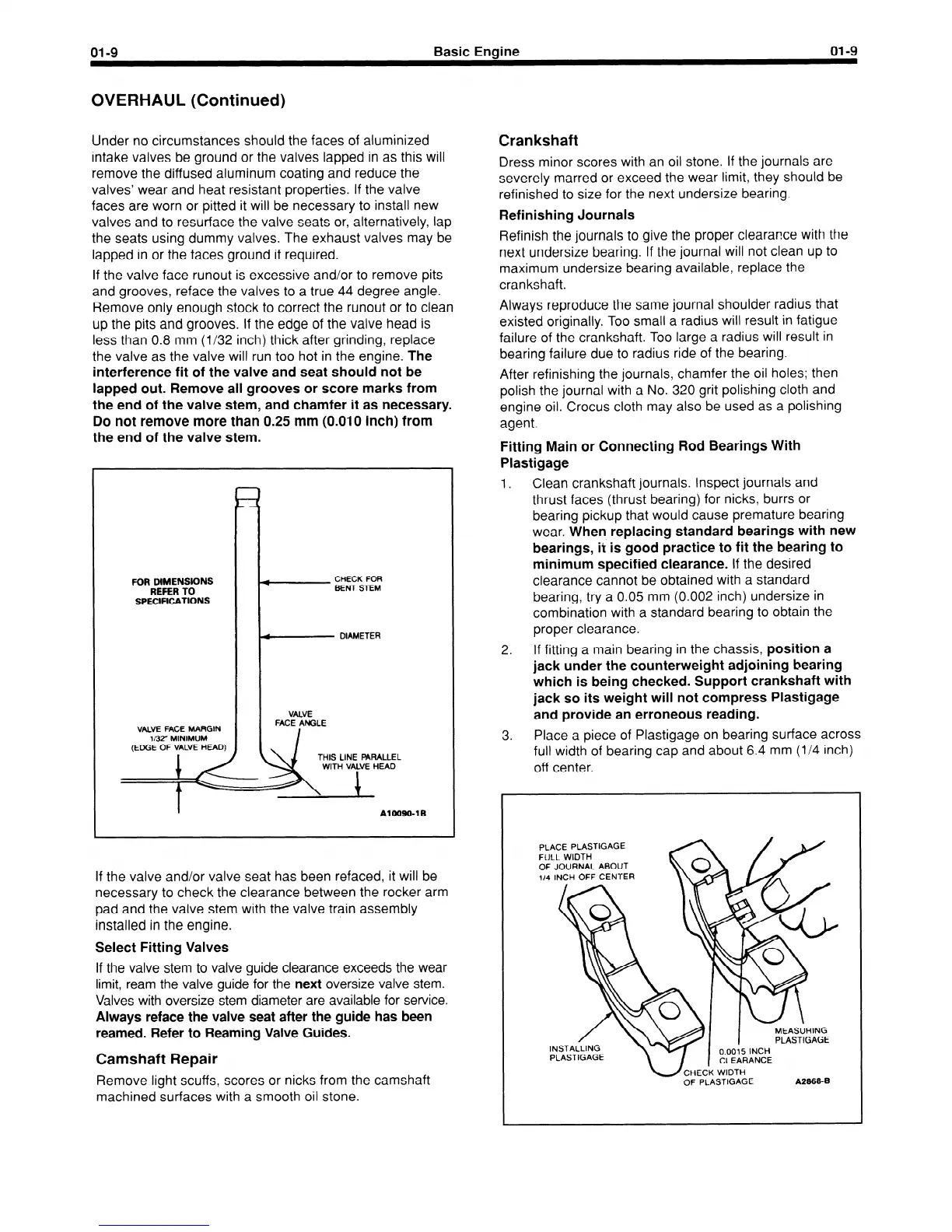

Fitting Main or Connecting Rod Bearings With

Plastigage

1.

Clean crankshaft journals. Inspect journals and

thrust faces (thrust bearing) for nicks, burrs or

bearing pickup that would cause premature bearing

wear.

When replacing standard bearings with new

bearings, it is good practice to fit the bearing to

minimum specified clearance.

If the desired

clearance cannot be obtained with a standard

bearing, try a 0.05 mm (0.002 inch) undersize in

combination with a standard bearing to obtain the

proper clearance.

2. If fitting a main bearing in the chassis,

position a

jack under the counterweight adjoining bearing

which is being checked. Support crankshaft with

jack so its weight will not compress Plastigage

and provide an erroneous reading.

3. Place a piece of Plastigage on bearing surface across

full width of bearing cap and about 6.4 mm (l/4 inch)

off center.

PLACE PLASTIGAGE

FULL WIDTH

OF JOURNAL ABOUT

114

INCH OFF CENTER

INSTALLING

PLASTIGAGE

-CHECK WIDTH

OF PLASTIGAGE

A28684

Loading...

Loading...