01-27

Basic Enaine

01-27

REMOVAL AND INSTALLATION (Continued)

When installing the ring gear it must be heated evenly to a

temperature of 260 to 280°C (500535°F). Do not exceed

290°C (554°F) as the ring gear wear resistant properties

will be destroyed. If the ring gear is to be heated by direct

flame, place the ring gear on a metal plate approximately 2

to 3 mm (.079--J 18 in.) thick and heat plate from below in

the area of the ring gear until it reaches the required

temperature. The correct temperature can be detected by

using a special type of temperature sensitive crayon. Fit

the ring gear with the chamfers on the leading faces of the

gear teeth relative to the direction of rotation. Allow the ring

gear to cool naturally in air.

Do not quench.

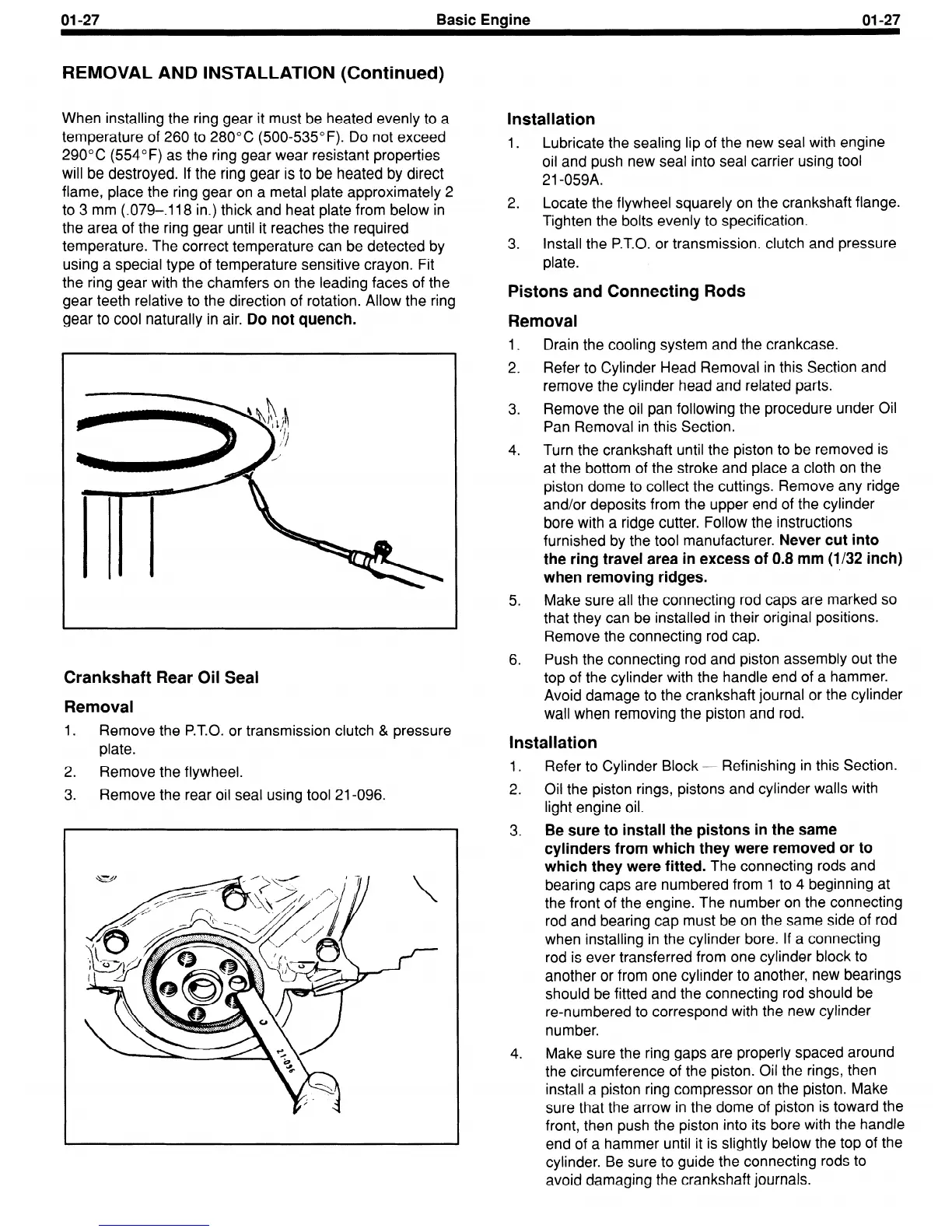

Crankshaft Rear Oil Seal

Removal

1.

Remove the P.T.O. or transmission clutch & pressure

plate.

2. Remove the flywheel.

3. Remove the rear oil seal using tool 21-096.

Installation

1. Lubricate the sealing lip of the new seal with engine

oil and push new seal into seal carrier using tool

21-059A.

2.

Locate the flywheel squarely on the crankshaft flange.

Tighten the bolts evenly to specification.

3. Install the P.T.O. or transmission. clutch and pressure

plate.

Pistons and Connecting Rods

Removal

1.

2.

3.

4.

5.

6.

Drain the cooling system and the crankcase.

Refer to Cylinder Head Removal in this Section and

remove the cylinder head and related parts.

Remove the oil pan following the procedure under Oil

Pan Removal in this Section.

Turn the crankshaft until the piston to be removed is

at the bottom of the stroke and place a cloth on the

piston dome to collect the cuttings. Remove any ridge

and/or deposits from the upper end of the cylinder

bore with a ridge cutter. Follow the instructions

furnished by the tool manufacturer.

Never cut into

the ring travel area in excess of 0.8 mm (1132 inch)

when removing ridges.

Make sure all the connecting rod caps are marked so

that they can be installed in their original positions.

Remove the connecting rod cap.

Push the connecting rod and piston assembly out the

top of the cylinder with the handle end of a hammer.

Avoid damage to the crankshaft journal or the cylinder

wall when removing the piston and rod.

Installation

1. Refer to Cylinder Block - Refinishing in this Section.

2. Oil the piston rings, pistons and cylinder walls with

light engine oil.

3.

Be sure to install the pistons in the same

cylinders from which they were removed or to

which they were fitted.

The connecting rods and

bearing caps are numbered from 1 to 4 beginning at

the front of the engine. The number on the connecting

rod and bearing cap must be on the same side of rod

when installing in the cylinder bore. If a connecting

rod is ever transferred from one cylinder block to

another or from one cylinder to another, new bearings

should be fitted and the connecting rod should be

re-numbered to correspond with the new cylinder

number.

4. Make sure the ring gaps are properly spaced around

the circumference of the piston. Oil the rings, then

install a piston ring compressor on the piston. Make

sure that the arrow in the dome of piston is toward the

front, then push the piston into its bore with the handle

end of a hammer until it is slightly below the top of the

cylinder. Be sure to guide the connecting rods to

avoid damaging the crankshaft journals.

Loading...

Loading...