01-15

Basic Enaine

01-15

CLEANING AND INSPECTION (Continued)

A

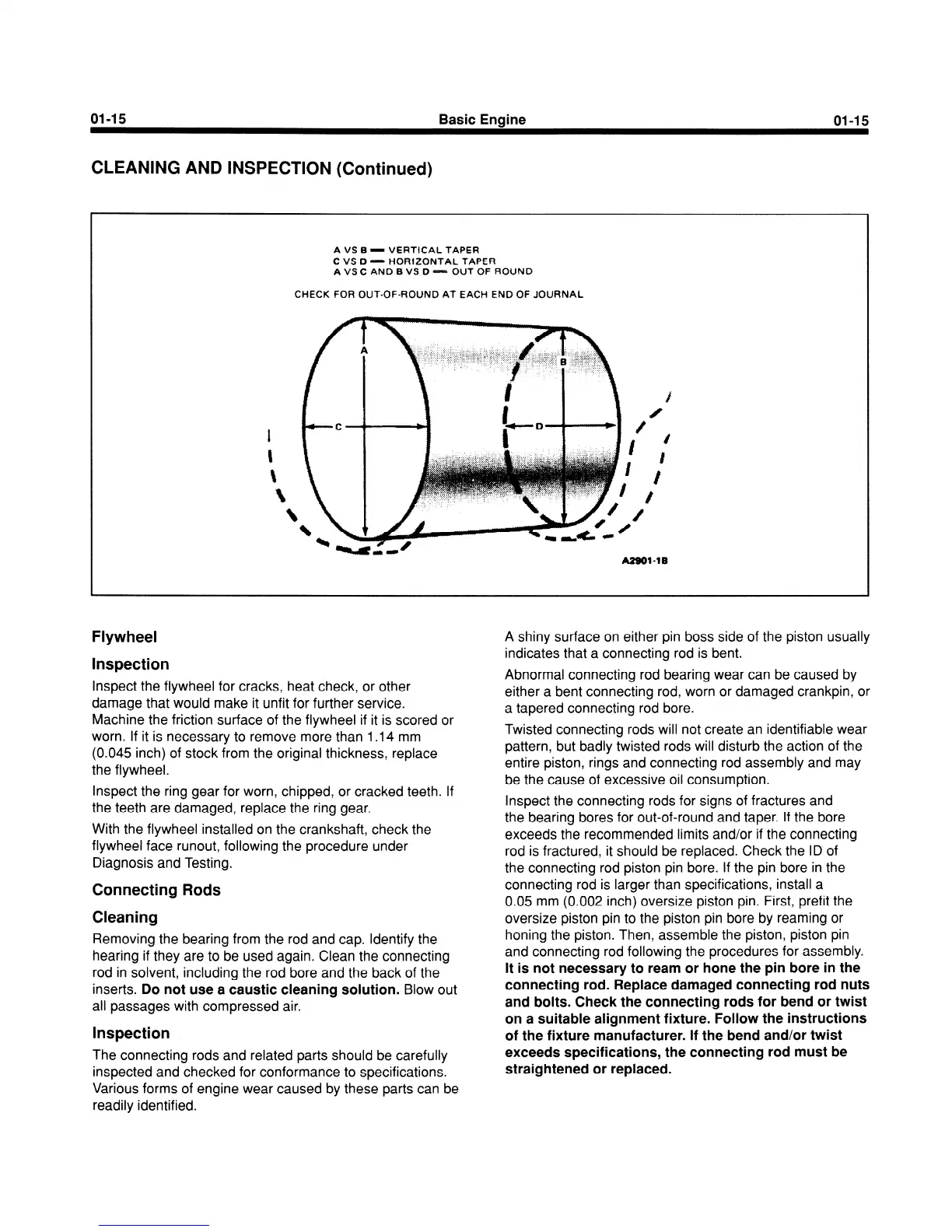

VS 6 - VERTtCAL TAPER

C VS D - HOR12ONTAL TAF’ER

A

VS C AND B VS D - OUT OF ROUND

CHECK FOR OUT-OF-ROUND AT EACH END OF JOURNAL

Flywheel

Inspection

Inspect the flywheel for cracks, heat check, or other

damage that would make it unfit for further service.

Machine the friction surface of the flywheel if it is scored or

worn. If it is necessary to remove more than 1 .I 4 mm

(0.045 inch) of stock from the original thickness, replace

the flywheel.

Inspect the ring gear for worn, chipped, or cracked teeth. If

the teeth are damaged, replace the ring gear.

With the flywheel installed on the crankshaft, check the

flywheel face runout, following the procedure under

Diagnosis and Testing.

Connecting Rods

Cleaning

Removing the bearing from the rod and cap. Identify the

hearing if they are to be used again. Clean the connecting

rod in solvent, including the rod bore and the back of the

inserts.

Do not use a caustic cleaning solution.

Blow out

all passages with compressed air.

Inspection

The connecting rods and related parts should be carefully

inspected and checked for conformance to specifications.

Various forms of engine wear caused by these parts can be

readily identified.

A shiny surface on either pin boss side of the piston usually

indicates that a connecting rod is bent.

Abnormal connecting rod bearing wear can be caused by

either a bent connecting rod, worn or damaged crankpin, or

a tapered connecting rod bore.

Twisted connecting rods will not create an identifiable wear

pattern, but badly twisted rods will disturb the action of the

entire piston, rings and connecting rod assembly and may

be the cause of excessive oil consumption.

Inspect the connecting rods for signs of fractures and

the bearing bores for out-of-round and taper. If the bore

exceeds the recommended limits and/or if the connecting

rod is fractured, it should be replaced. Check the ID of

the connecting rod piston pin bore. If the pin bore in the

connecting rod is larger than specifications, install a

0.05 mm (0.002 inch) oversize piston pin. First, prefit the

oversize piston pin to the piston pin bore by reaming or

honing the piston. Then, assemble the piston, piston pin

and connecting rod following the procedures for assembly.

It is not necessary to ream or hone the pin bore in the

connecting rod. Replace damaged connecting rod nuts

and bolts. Check the connecting rods for bend or twist

on a suitable alignment fixture. Follow the instructions

of the fixture manufacturer. If the bend and/or twist

exceeds specifications, the connecting rod must be

straightened or replaced.

Loading...

Loading...