01-14

Basic Enaine

01-14

CLEANING AND INSPECTION (Continued)

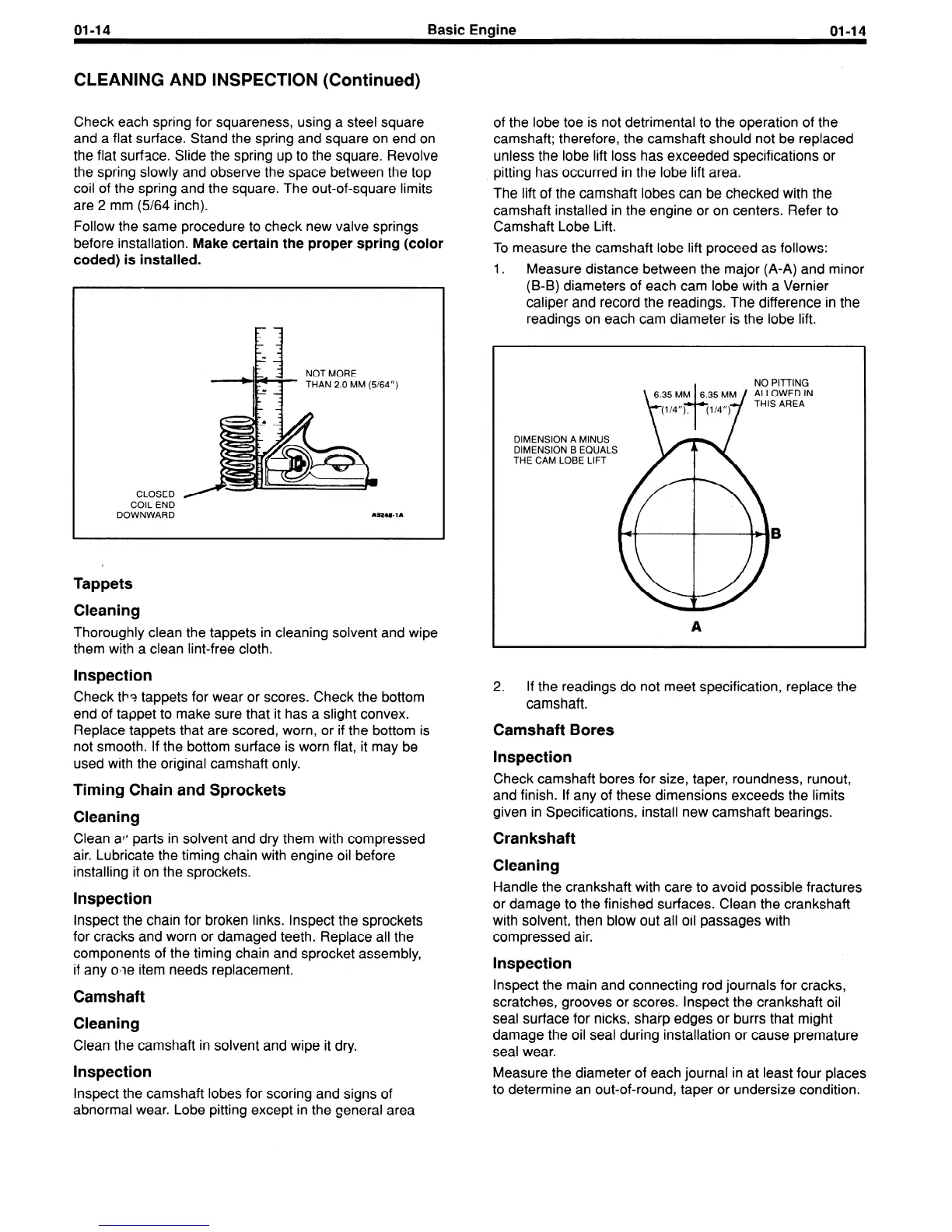

Check each spring for squareness, using a steel square

and a flat surface. Stand the spring and square on end on

the flat surface. Slide the spring up to the square. Revolve

the spring slowly and observe the space between the top

coil of the spring and the square. The out-of-square limits

are 2 mm (5/64 inch).

Follow the same procedure to check new valve springs

before installation.

Make certain the proper spring (color

coded) is installed.

CLOSED

COIL END

DOWNWARD

NOT MORE

THAN 2.0 MM (5/64”)

Tappets

Cleaning

Thoroughly clean the tappets in cleaning solvent and wipe

them with a clean lint-free cloth.

Inspection

Check th? tappets for wear or scores. Check the bottom

end of tappet to make sure that it has a slight convex.

Replace tappets that are scored, worn, or if the bottom is

not smooth. If the bottom surface is worn flat, it may be

used with the original camshaft only.

Timing Chain and Sprockets

Cleaning

Clean a!’ parts in solvent and dry them with compressed

air. Lubricate the timing chain with engine oil before

installing it on the sprockets.

Inspection

Inspect the chain for broken links. Inspect the sprockets

for cracks and worn or damaged teeth. Replace all the

components of the timing chain and sprocket assembly,

if any o,le item needs replacement.

Camshaft

Cleaning

Clean the camshaft in solvent and wipe it dry.

Inspection

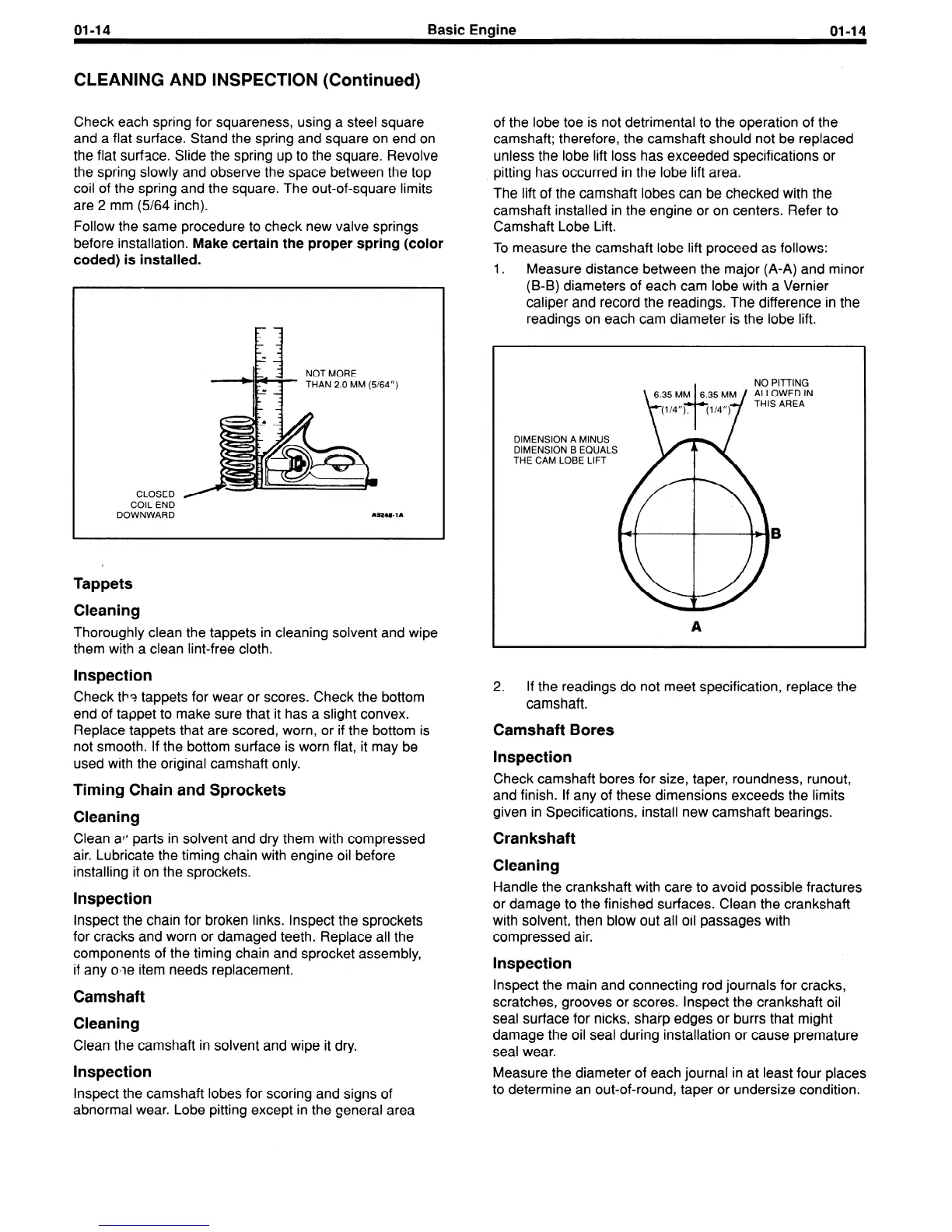

Inspect the camshaft lobes for scoring and signs of

abnormal wear. Lobe pitting except in the general area

of the lobe toe is not detrimental to the operation of the

camshaft; therefore, the camshaft should not be replaced

unless the lobe lift loss has exceeded specifications or

pitting has occurred in the lobe lift area.

The lift of the camshaft lobes can be checked with the

camshaft installed in the engine or on centers. Refer to

Camshaft Lobe Lift.

To measure the camshaft lobe lift proceed as follows:

1.

Measure distance between the major (A-A) and minor

(B-B) diameters of each cam lobe with a Vernier

caliper and record the readings. The difference in the

readings on each cam diameter is the lobe lift.

t t

NO PITTING

6.35 MM 6.35 MM

f

ALLOWED IN

(l/4”),

(l/4”)

THIS AREA

DIMENSION A

DIMENSION B

THE CAM LOB

MINUS

EQUAL

IE LIFT

A

2.

If the readings do not meet specification, replace the

camshaft.

Camshaft Bores

Inspection

Check camshaft bores for size, taper, roundness, runout,

and finish. If any of these dimensions exceeds the limits

given in Specifications, install new camshaft bearings.

Crankshaft

Cleaning

Handle the crankshaft with care to avoid possible fractures

or damage to the finished surfaces. Clean the crankshaft

with solvent, then blow out all oil passages with

compressed air.

Inspection

Inspect the main and connecting rod journals for cracks,

scratches, grooves or scores. Inspect the crankshaft oil

seal surface for nicks, sharp edges or burrs that might

damage the oil seal during installation or cause premature

seal wear.

Measure the diameter of each journal in at least four places

to determine an out-of-round, taper or undersize condition.

Loading...

Loading...