03-l 2

Fuel Svstem

03-I 2

ZENITH MODEL #33 CARBURETOR (Continued)

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

e. Welch plug (31) over spark vacuum port

f. Spark vacuum tube (32) to approximately 14 mm

(9/l 6 inch) from casting

g. Throttle body plug (36) flush

h. Pump check valve (42) flush using tool Cl 51-53.

i.

Well tube (44) making sure that end openings

align with notch in casting at top and fuel channel

at bottom.

Slide seal (33) over throttle shaft with lip toward lever

and install shaft in body.

Back out throttle stop screw (35) and pace body on

bench with mounting flange up.

With milled flat up, install throttle plate (30) with short

side toward idle port and start screws (28). Make sure

beveled sides of plate are next to throttle body bore.

Tap the plate lightly (plate held closed) to center it and

tighten screws.

While holding throttle closed, screw idle stop screw

(35) in until it touches the casting, then screw in an

additional 3/4 turn.

Install idle needle (27) washer (56) and spring (26)

and screw in to gently touch the seat. Back screw out

approximately one turn.

Install power jet valve (14) using Cl 61-9 wrench. No

gasket required.

Install main jet (22) and seat firmly with screwdriver.

No gasket required.

Install main jet plug (20) and washer (21) and tighten

securely. If main jet adjustment or solenoid shutoff are

used, install in place of plug.

Turn body right side up. Insert float axle (13) into

holes in float (12).

Lower float axle and float into slot provided in body

with the float needle sticking into the threaded

opening.

Install the fuel valve seat (19) and washer (18)

making sure that the fuel valve enters the seat

properly (the valve will enter the seat more easily if

the float is held in the up position) and tighten

securely.

Insert float axle clip (11) in slot to bear against axle

ends. Holding axle in place, raise float by applying

light finger pressure to the float bracket. Float

pontoons should be approximately level when the

valve is seated. If not, bend tab to carefully adjust.

Install O-ring (54) on venturi skirt and place venturi

(IO) into recess provided in body making sure that the

nozzle (9) lines up with the notch in the fuel well.

Place intake gasket (8) in position on body.

NOTE: If you have an older model unit with

removable accelerator jet; after intake gasket (8) is in

place, an additional washer (55) will be assembled

over the accelerator jet tube (47) and set inside the

large hole in the intake gasket (8) and on top of the

smaller washer (48). Lower air intake carefully onto

bowl and fasten securely and evenly using attaching

screws (5).

16. Place accelerator pump diaphragm (37) in place on

body with bagged section into cavity. Insert

diaphragm protector (38) into end of spring (39) and

install spring with protector against diaphragm.

17. Place cover (40) over spring and compress. Insert

screws (41) and tighten evenly and securely.

NOTE: Pump spacer (57) will install into cover before

assembly if required.

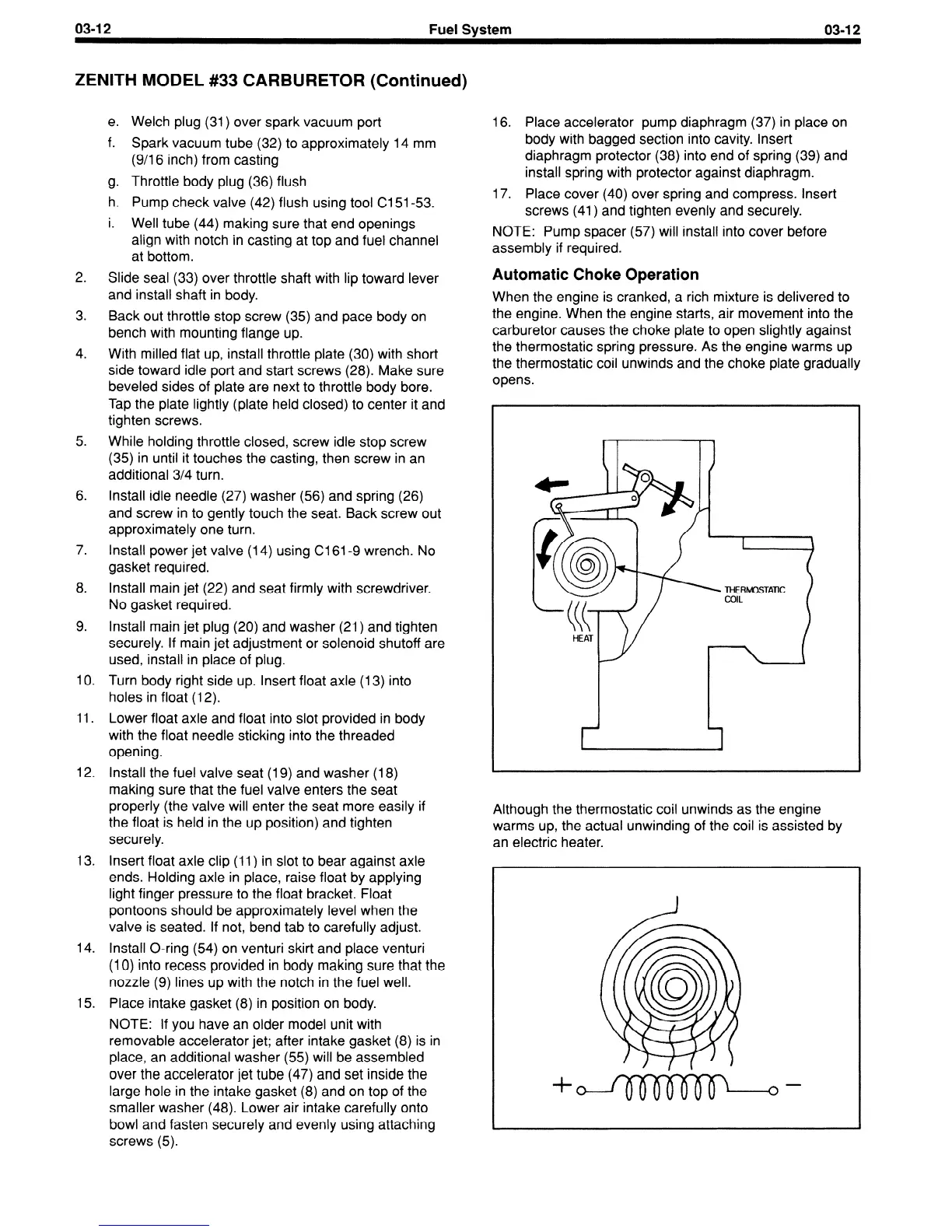

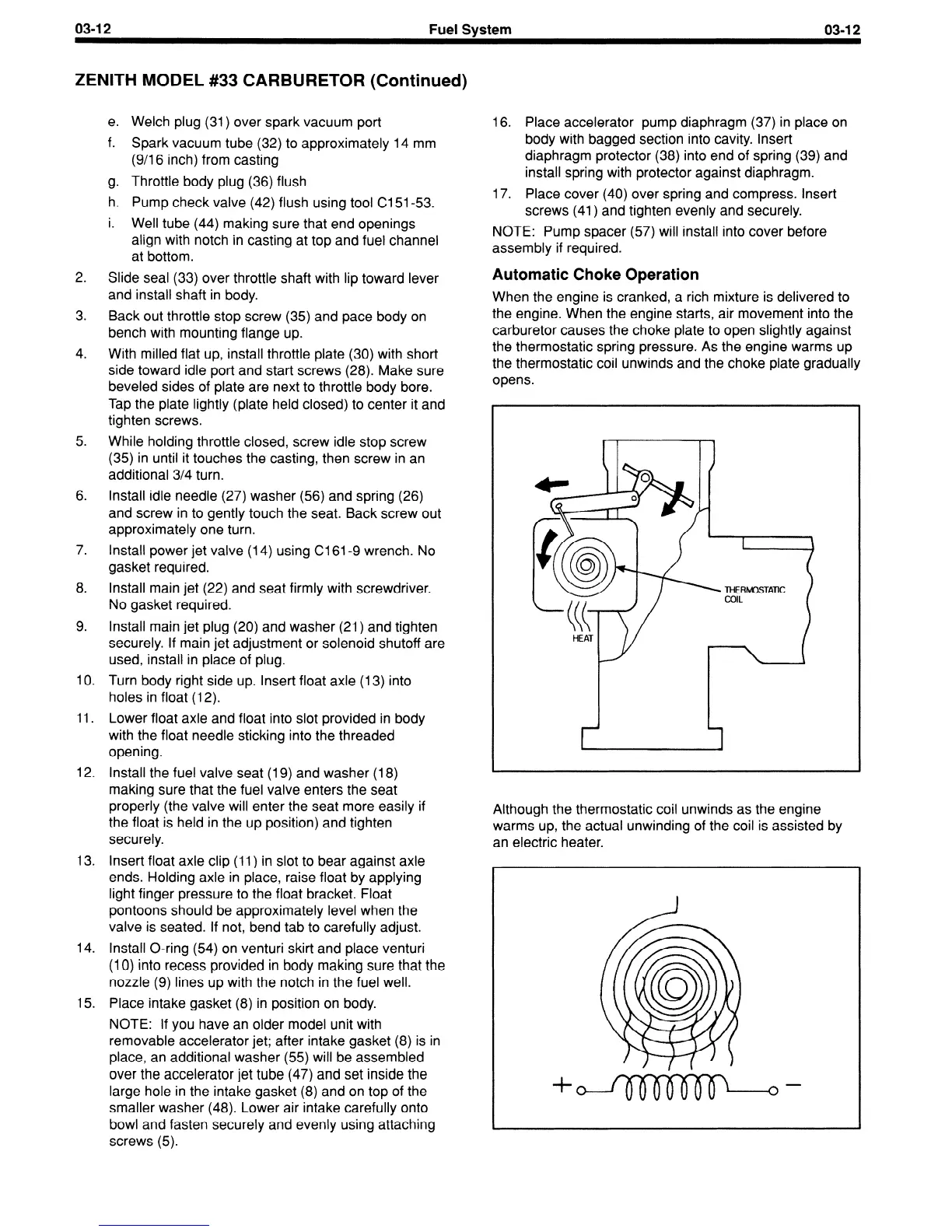

Automatic Choke Operation

When the engine is cranked, a rich mixture is delivered to

the engine. When the engine starts, air movement into the

carburetor causes the choke plate to open slightly against

the thermostatic spring pressure. As the engine warms up

the thermostatic coil unwinds and the choke plate gradually

opens.

Loading...

Loading...