01-5

Basic Engine

01-5

DESCRIPTION (Continued)

The spark plugs have a tapered seat without a sealing ring.

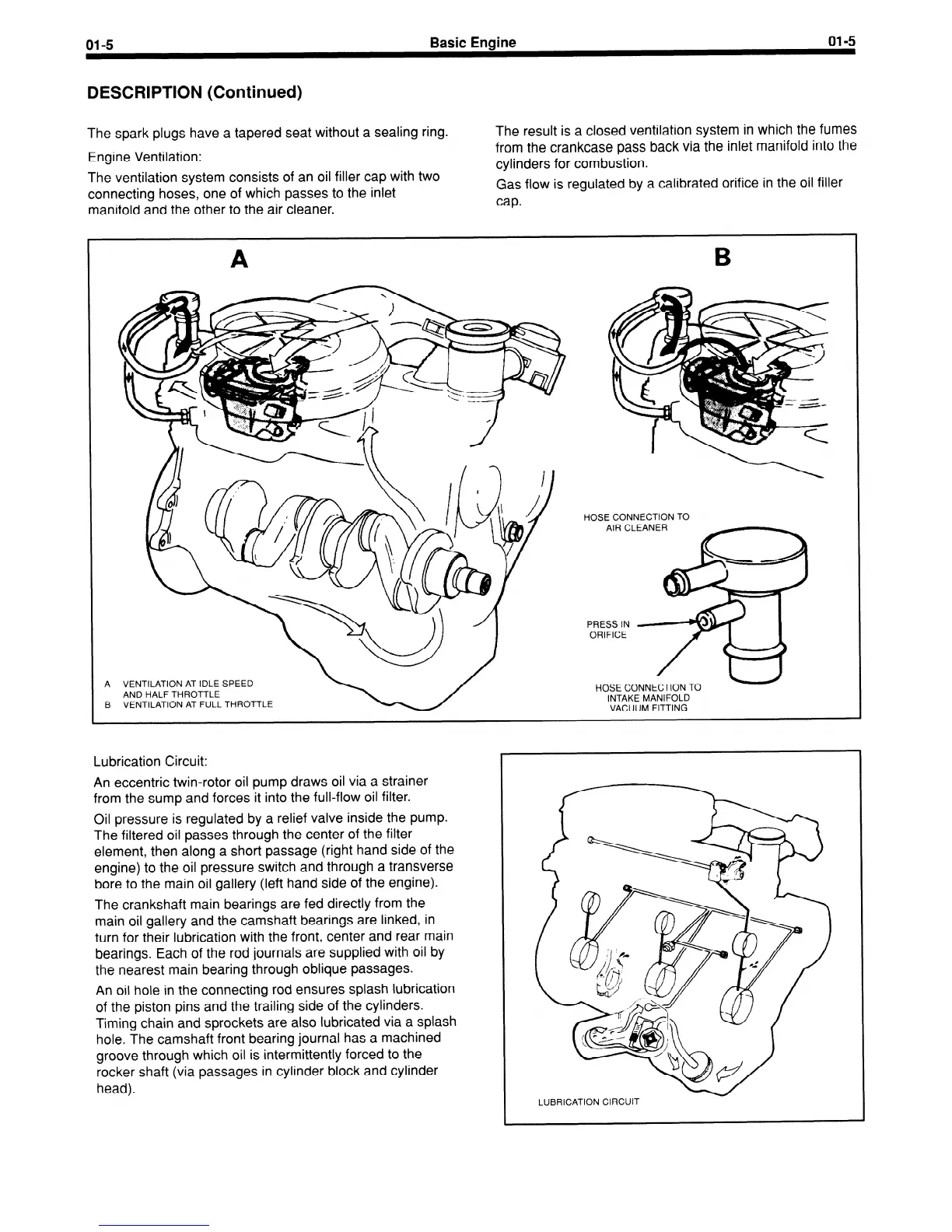

The result is a closed ventilation system in which the fumes

Engine Ventilation:

from the crankcase pass back via the inlet manifold into the

The ventilation system consists of an oil filler cap with two

cylinders for combustion.

connecting hoses, one of which passes to the inlet

Gas flow is regulated by a calibrated orifice in the oil filler

manifold and the other to the air cleaner.

cap.

A VENTILATION AT IDLE SPEED

AND HALF THROTTLE

B VENTILATION AT FULL THROTTLE

HOSE CONNECTION

TO

AIR C

PRESS IN

ORIFICE

HOSE C

INTAKE MANIFOLD

VACUUM FITTING

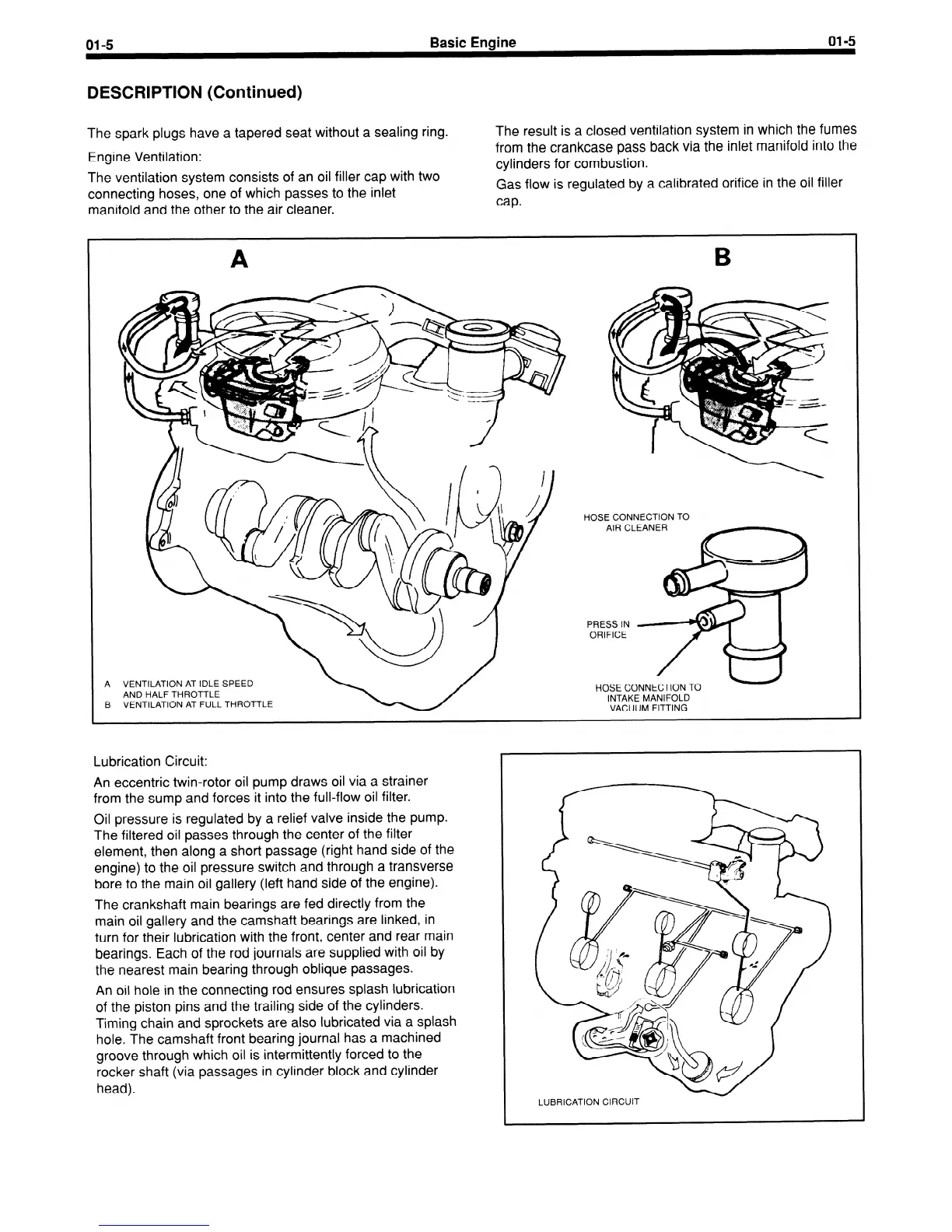

Lubrication Circuit:

An eccentric twin-rotor oil pump draws oil via a strainer

from the sump and forces it into the full-flow oil filter.

Oil pressure is regulated by a relief valve inside the pump.

The filtered oil passes through the center of the filter

element, then along a short passage (right hand side of the

engine) to the oil pressure switch and through a transverse

bore to the main oil gallery (left hand side of the engine).

The crankshaft main bearings are fed directly from the

main oil gallery and the camshaft bearings are linked, in

turn for their lubrication with the front, center and rear main

bearings. Each of the rod journals are supplied with oil by

the nearest main bearing through oblique passages.

An oil hole in the connecting rod ensures splash lubrication

of the piston pins and the trailing side of the cylinders.

Timing chain and sprockets are also lubricated via a splash

hole. The camshaft front bearing journal has a machined

groove through which oil is intermittently forced to the

rocker shaft (via passages in cylinder block and cylinder

head).

LUBRICATION CIRCUIT

Loading...

Loading...