TIG Operating Modes

General

WARNING!

Danger due to incorrect operation.

This can result in severe personal injury and damage to property.

▶

Read these Operating Instructions

▶

All system component Operating Instructions, especially the safety rules

Follow the guidelines referring to setting, setting range, and units of measurement for the

available welding parameters in the chapter "Program level preferences".

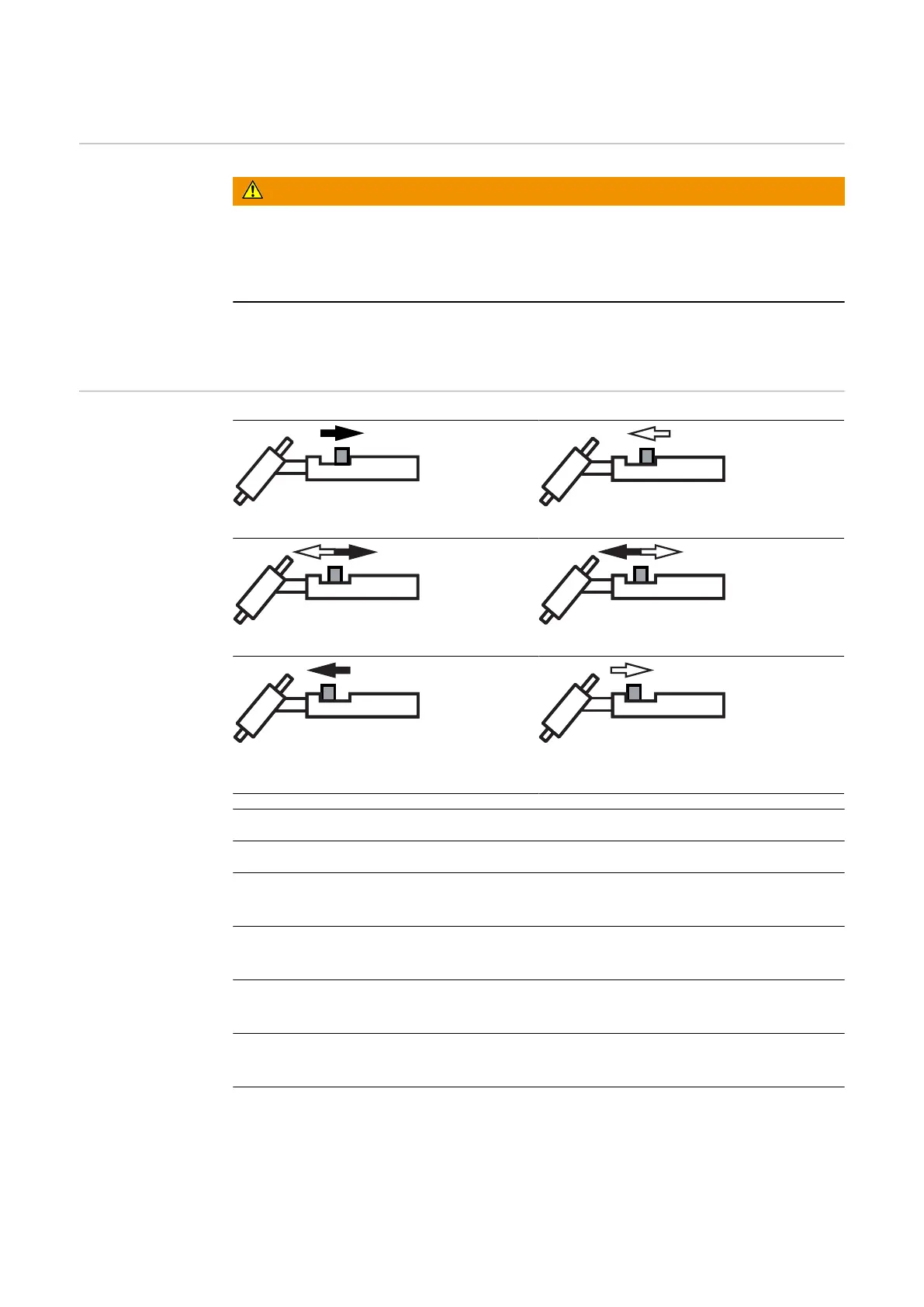

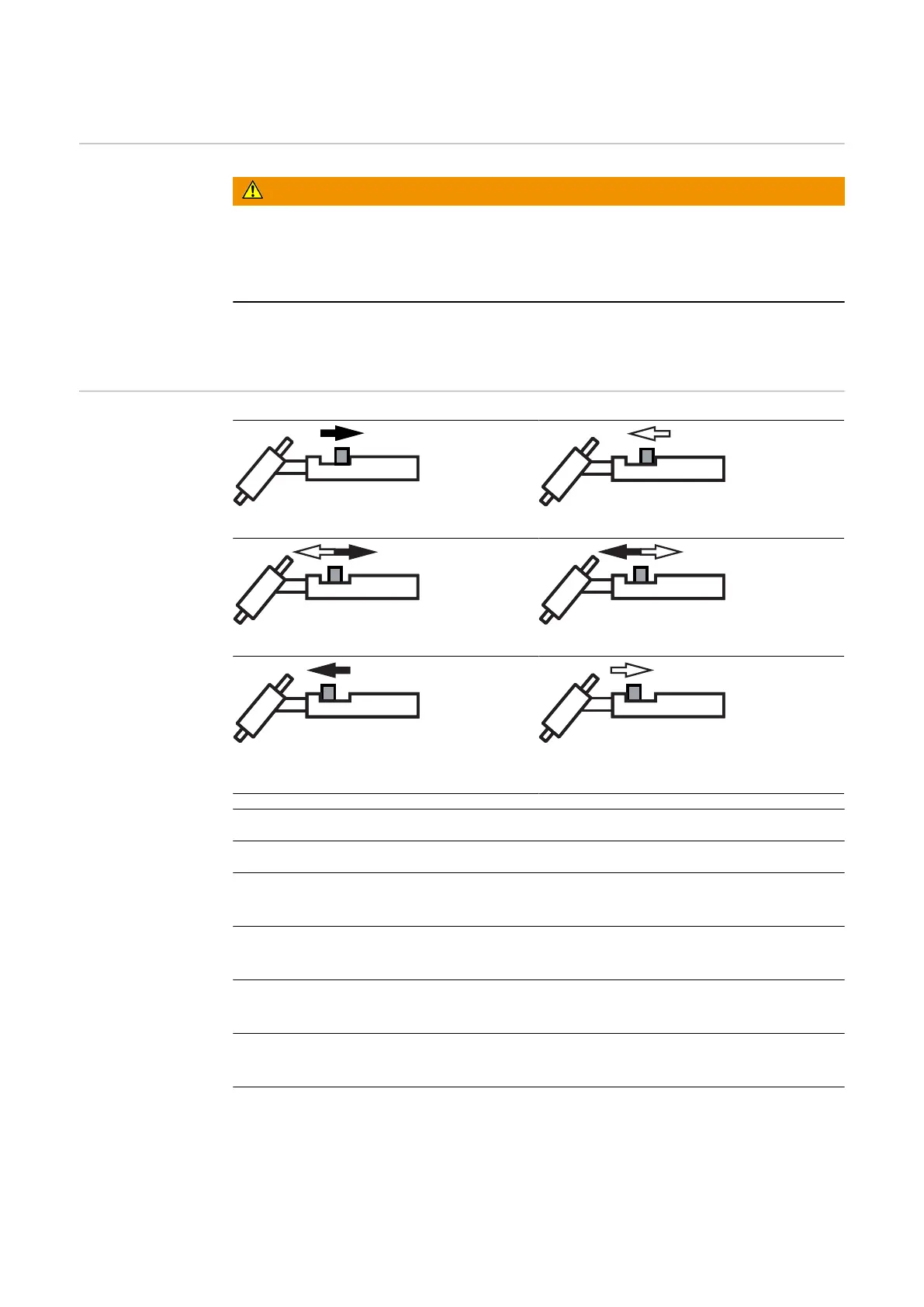

Symbols and

explanations

Pull back the torch trigger and hold it in this position

Release the torch trigger

Briefly pull the torch trigger back (<0.5 s)

Briefly push the torch trigger forwards (<0.5 s)

Push the torch trigger forward and hold it in this pos-

ition

Release the torch trigger

Explanation

GAS Gas pre-flow time

I

S

Starting-current phase:the temperature is raised gently at low welding current,

so that the filler metal can be positioned correctly

t

up

UpSlope phase: the starting current is continually increased up to the welding

current

I

H

Welding current phase:even heat input into the parent material whose temper-

ature is raised by the advancing heat

t

down

DownSlope phase: steady lowering of the welding current until it reaches the

final current.

I

E

Crater-fill phase:to avoid local overheating of the parent material caused by

heat accumulation at the end of welding. This prevents possible sagging of the

weld seam.

34

Loading...

Loading...