TIG foot remote control TR 52mc

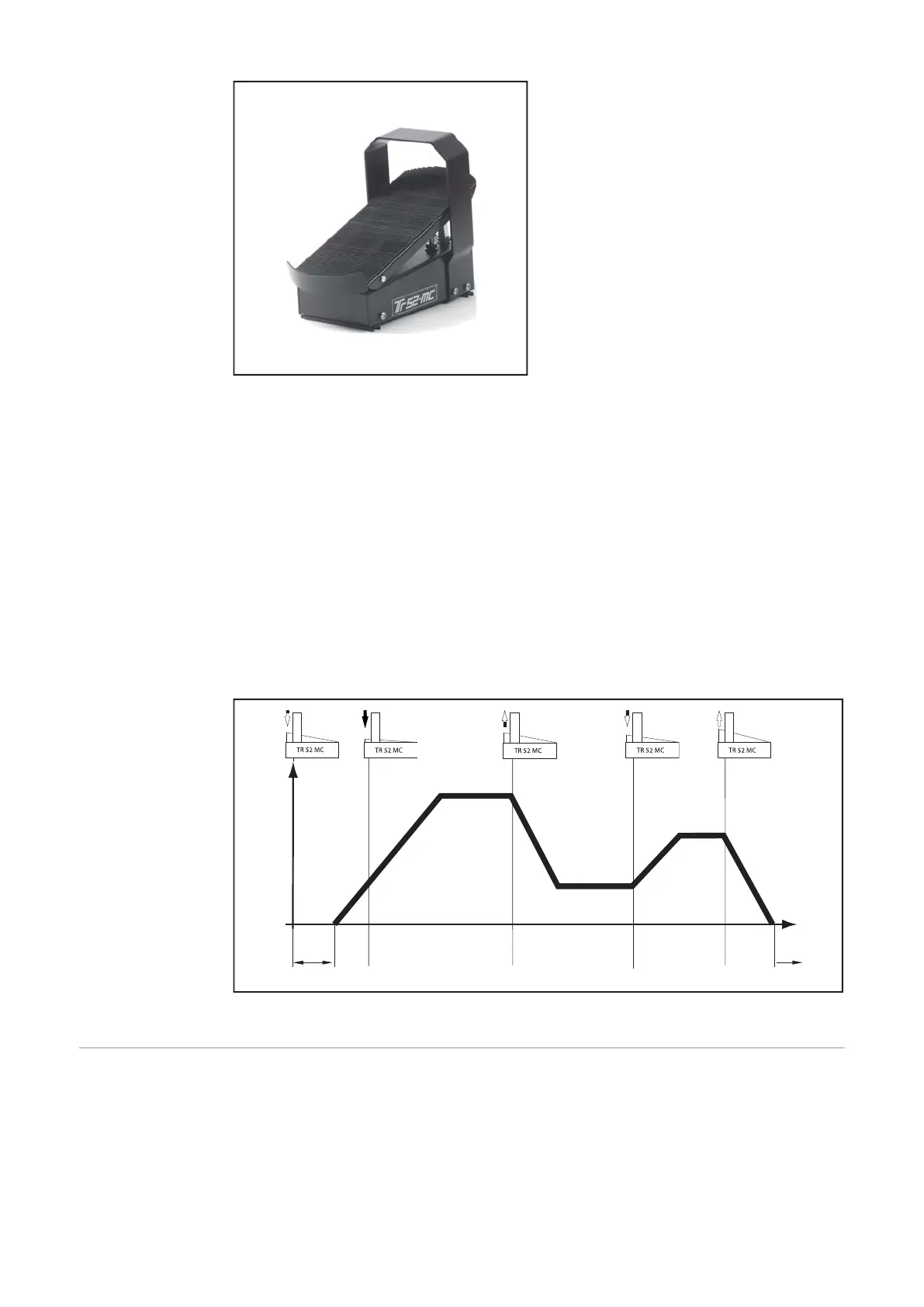

Function:

- 2-step mode indicator lights up as soon as the remote control is connected (auto-

matic switching)

- Set main current adjuster IH to desired maximum current

- Set gas pre-flow time and gas post-flow time directly at the power source (section

"Program level preferences”)

- Initiate ignition process by lightly stepping on the pedal

- Starting current IS, main current IH and final current can be controlled with the foot

pedal

Important! Welding current does not exceed the preselected value when the pedal is

depressed.

- Switch off welding current by completely depressing the pedal

- The welding process is interrupted, the gas post-flow time expires

Functional sequence with remote foot control TR 52mc

TIG spot welding

remote control

TR 51mc

Welding of stainless constructions in the thin sheet area is often not possible due to

severe material distortion. Likewise, joints that are only accessible from one side can be

easily mastered using the TIG spot process.

Important! Aluminum materials cannot usually be joined by TIG spot welding, or if so

then only poorly. The oxide skin between the sheets cannot be removed.

52

Loading...

Loading...