Page 23 of 28 Fuji Electric Europe GmbH

11. Travel optimization

The aim of this test is to achieve the same stopping position independently of the car load. If we can

achieve repeatability of stopping, independently of the car load, we only have to reduce (or increase)

inverter ramps or move lift magnets (or flags, etc.) in order to stop at floor level.

In this method, we will compare the landing position when the car is half loaded and when the car is

empty. When we have half load inside the car, we should have a balanced condition; in this case the slip

influences should be almost zero. Choose one floor and wait out of the car. Put half load in the car. First

call the lift to come to the floor where you are measuring in down direction (coming from an upper floor)

and measure (note) the distance where the lift has stopped (from the floor level).

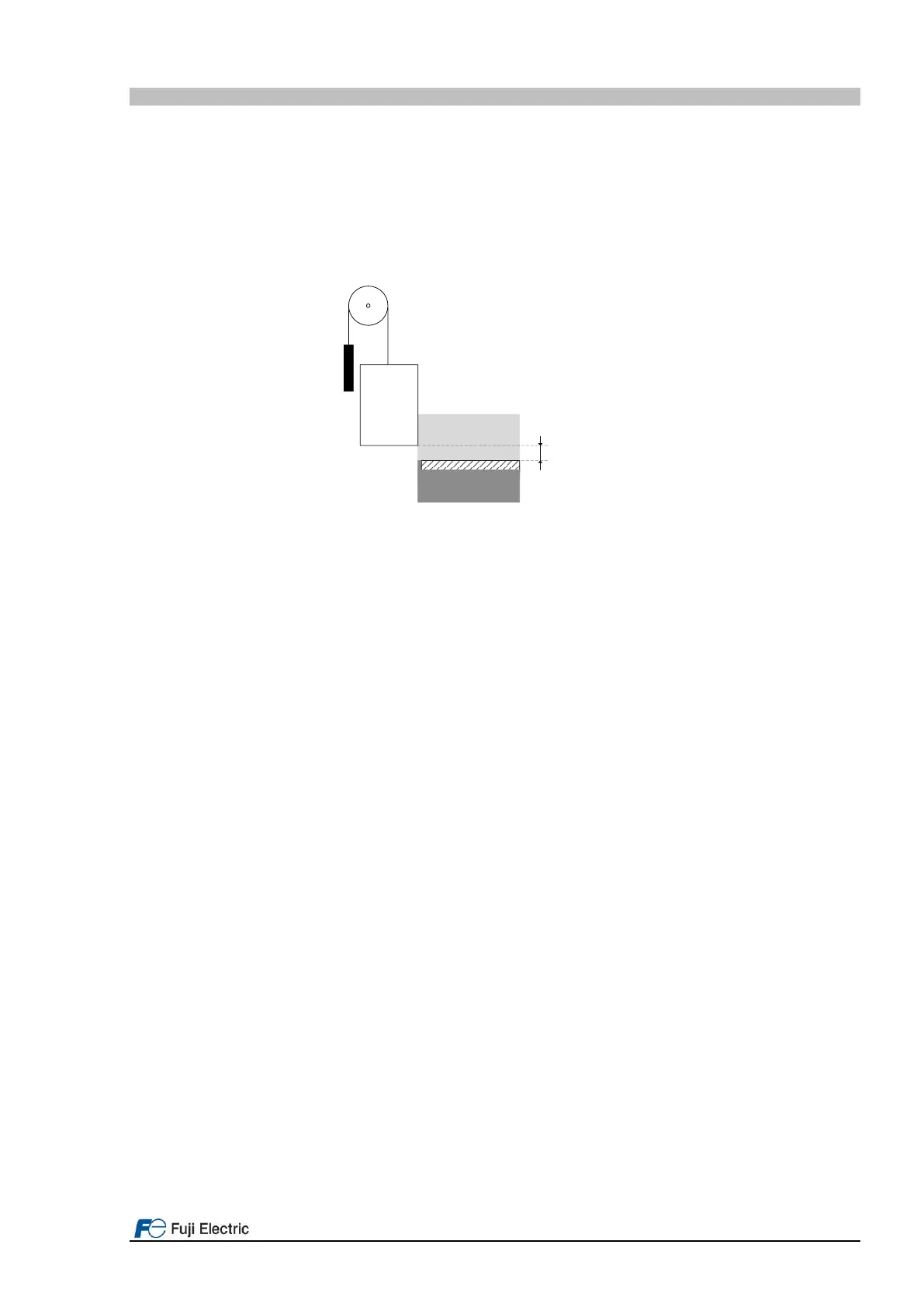

Figure 11.1 Cabin positioning at floor level

If the cabin is above the floor level, the distance is positive (Ex. +4mm); if the cabin is below the floor level,

the distance is negative (Ex. -13mm). Repeat the test (still with half load) calling the lift to come to the

floor where you are waiting in up direction (coming from a lower floor) and measure (note) the distance

where the lift has stopped (from the floor level).

Remove now the cabin load (empty cabin) and measure the stopping position when the cabin is going

down (coming from upper floor). Doing so, we are checking the slip in driving condition. Compare the

position with the one measured with half load:

- If the cabin landing position is higher without load than with half load it means that the slip is not

enough. We need to give more slip when the cabin is empty (with more slip the lift will go faster than

without load in driving condition); in this case increase P09 (slip compensation driving gain) by 10%

and measure again.

- If the cabin landing position is higher with half load than without load it means that the slip is too much.

We need to give less slip when the cabin is empty (with less slip the lift will go slower without load in

driving condition); in this case decrease P09 (slip compensation driving gain) by 10% and measure

again.

- If the cabin landing position is the same with half load and without load, there is no need to change

slip compensation driving gains. Slip frequency is correctly adjusted in driving condition.

Measure the stopping position when the cabin is going up (coming from a lower floor). Doing so, we are

checking the slip in braking condition. Compare the position with the one measured with half load:

- If the cabin landing position is higher without load than with half load it means that the slip is not

enough. We need to give more slip when the cabin is empty (with more slip the lift will go slower

without load in braking condition); in this case increase P10 (slip compensation braking gain) by 10%

and measure again.

- If the cabin landing position is higher with half load than without load it means that the slip is too much.

We need to give less slip when the cabin is empty (with less slip the lift will go faster without load in

braking condition); in this case decrease P10 (slip compensation braking gain) by 10% and measure

again.

- If the stop distance is the same with half load and without load, there is no need to change slip

compensation braking gains. Slip frequency is correctly adjusted in braking condition.

Loading...

Loading...