Page 24 of 28 Fuji Electric Europe GmbH

12. Lift fine tuning (troubleshooting)

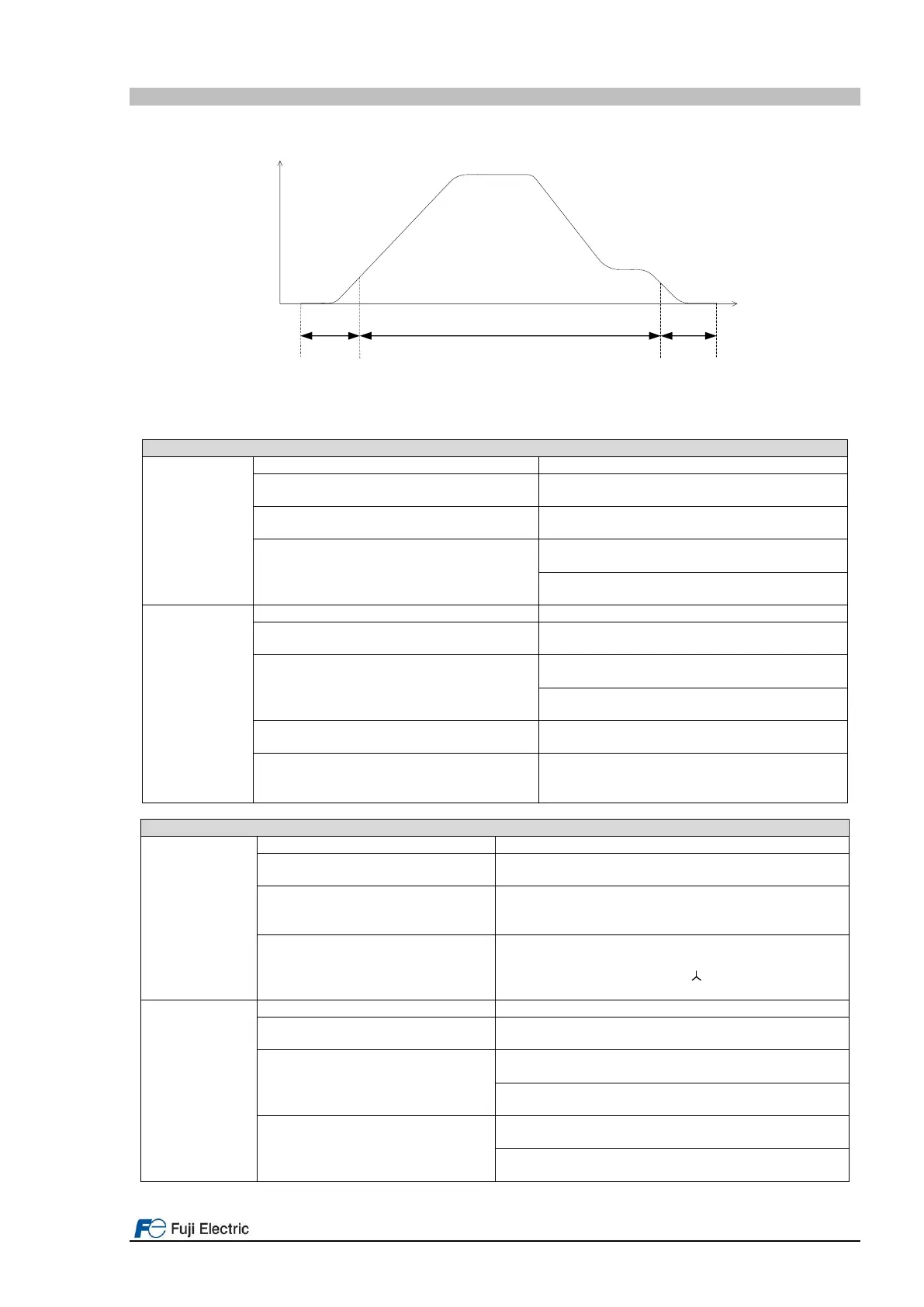

The typical problems have been divided in three different zones: starting, travel and stopping. Figure 14.1 shows a

standard lift travel divided in the three areas.

Speed

ON

ON

Time

ON

Starting StoppingTravel

Figure 14.1. Standard lift travel divided in three zones

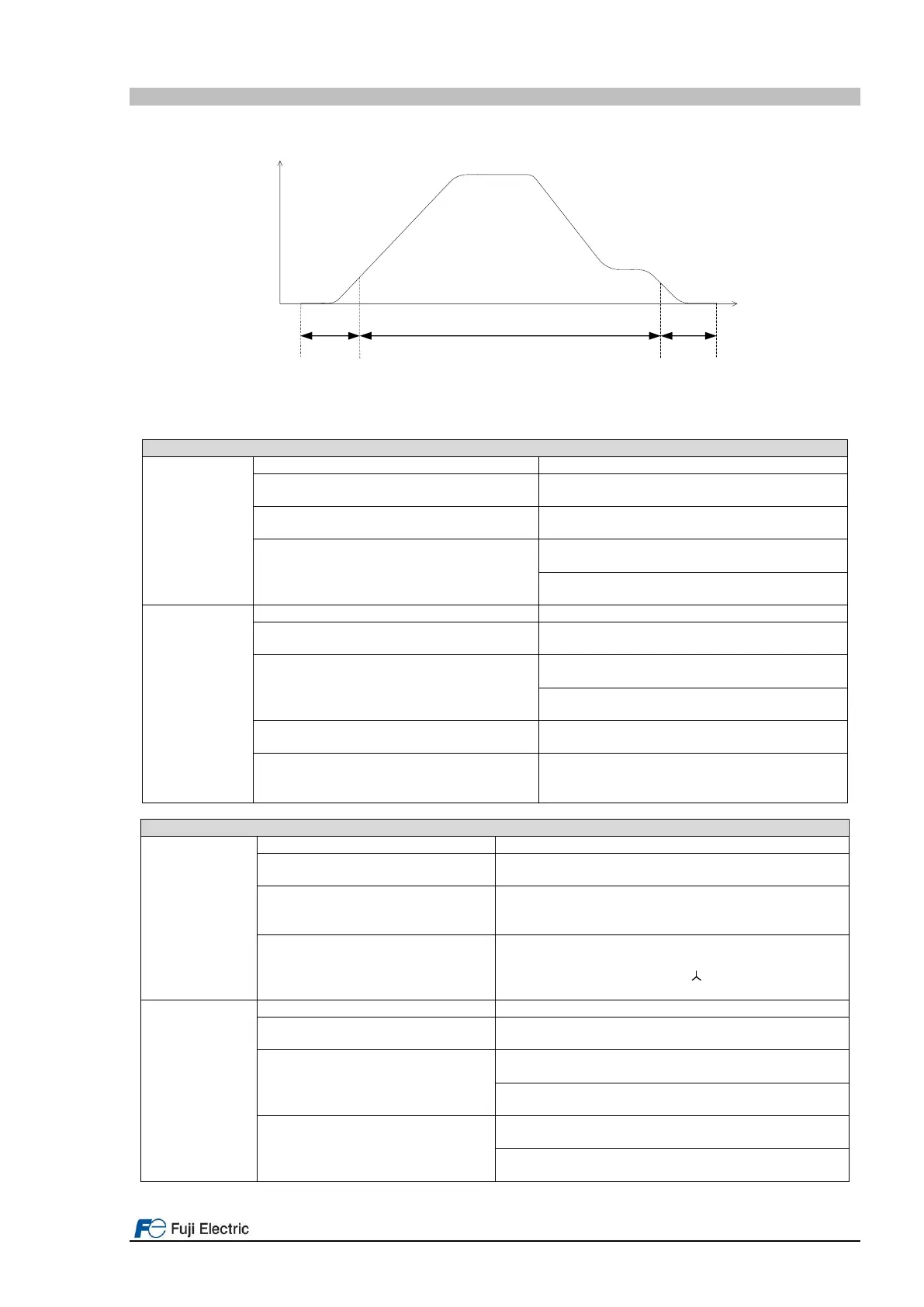

TROUBLESHOOTING (Starting)

Insufficient starting frequency

Increase F23

Max. F23=1.0 Hz

Increase L82

Max. L82=F24 – Brake reaction time

Increase P06

P06=30~70% of P03

Increase F09

Max. F09=5.0%

Too high starting frequency

Reduce F23

Min. F23=0.1 Hz

Reduce L82

Min. L82=0.20 s

Increase F24

Max. F24=1.5 s

Reduce P06

P06=30~70% of P03

Not related to inverters setting

Check brake operation

Check guides (oil, alignment, etc.)

Check car fixation (shoes)

VIBRATION AT

CONSTANT

SPEED

Decrease P06

P06=30~70% of P03

Reduce HIGH speed (i.e. C11)

Set motors rated speed instead of motor synchronous

speed

Not related to inverters setting

Check guides (oil, alignment, etc.)

Check car fixation (shoes)

Check motor connection (Δ or )

Check motor gearbox

UNDERSHOOT

FROM HIGH

SPEED TO

CREEP SPEED

Reduce P12

Min. P12=0.1 Hz

Deceleration too fast

(NOTE: Control that creep speed is

kept)

Increase deceleration ramp (i.e. E13)

Max. E10-E16, F07-F08=2.00 s

Increase 2nd S-curve at deceleration (i.e. L25)

Max. L19-L28, H57-H60=50 %

Increase P06

P06=30~70% of P03

Increase F09

Max. F09=5.0%

Loading...

Loading...