36 Design and specifications are subject to change without notice 01/2008

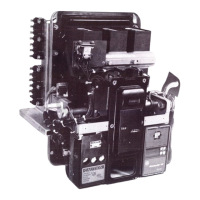

6. Inspections and maintenance

6.1 List of inspections

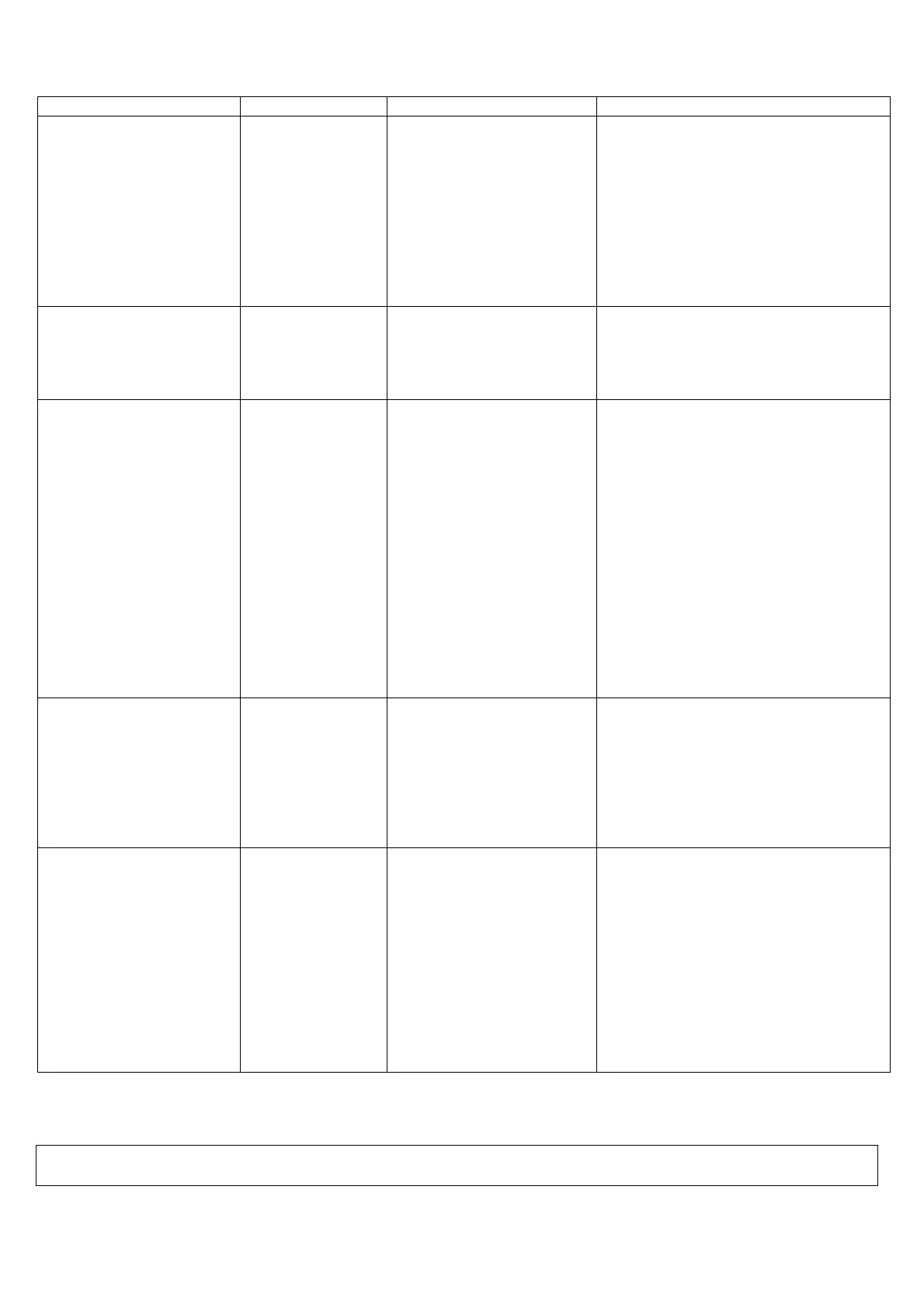

TYPE OF THE INSPECTION BY WHOM HOW OFTEN WHAT TO DO/CHECK

A. General visual inspection Customer.

Trained technician.

Every 6-12 months

• Check out damages or cracks of the

frame, adapter or arc chute

• Check out for missing screws or caps

• Check out for deglutinated labels

• Check out for corrosion

• Check out distinct manifestations of

flame or smoke at the frame

• Clean the breaker from dirt and dust

• Clean and degrease the cooper ter-

minals

B. General functional in-

spection

Customer.

Trained technician.

Every 6-12 months

• Close and open manually the breaker

to check the drive and mechanism

• Close the breaker electrically and

open by trip unit(s) releasing, to check

controls

C. Inspection of the arc

chute and contact system

Customer.

Trained technician.

Every 6-12 months

OR after:

• high short circuit open-

ing at >25kA

• >300 openings at load

current

• >100 openings at over

current load (2-3 *In)

• Check out wear of the arc runners;

shall not exceed 30% of its cross sec-

tion

• Check out wear of the pre-arcing

contact. It shall not exceed 2mm

[0,08in].

• Check out wear of the main contacts

at fix and flexible side; shall not ex-

ceed 1mm [0,04in] of its depth.

• Check out wear of the arc chute’s

plates; check out for deposits inside

of arc chute, this area shall be free of

deposits.

• Check out wear of protective walls;

shall not exceed 1mm [0,04].

• Check out contacts’ tilt and gaps.

D. Inspection of the screw

connections

Customer.

Trained technician.

Every 6-12 months

OR after every inspection:

• of the arc runners

• of the contacts

• of the arc chute

Check out position of the countersunk

screws in the sidewalls.

Check for tight fitting or use torque tool

(torque in SI and Imperial units):

• M8 ~20Nm [~ 177 lbf*in]

• M6 ~10Nm [~ 88 lbf*in]

• M5 ~5Nm [~ 44 lbf*in]

• M4 ~3Nm [~ 26 lbf*in]

E. Inspection of the me-

chanic components

GE.

Service technician.

Every 5 years

OR

After 5.000 openings

• Carry out inspection B

• Check out settings of contacts and

auxiliary switches

• Check out upper dumper of the

mechanism; no cracks, deformation

or heavy discolouration; hard consis-

tency; without punctures

• Check out main flexband breakage;

shall not exceed 30% of its cross sec-

tion

• Check out wear of mini flexband; shall

not exceed 30% of its cross section

Table 3

Required tools:

Cleaning tissue, pocket lamp, hand lever, hexagon wrench SW5, SW6, small and medium screwdriver.

Loading...

Loading...