5-7

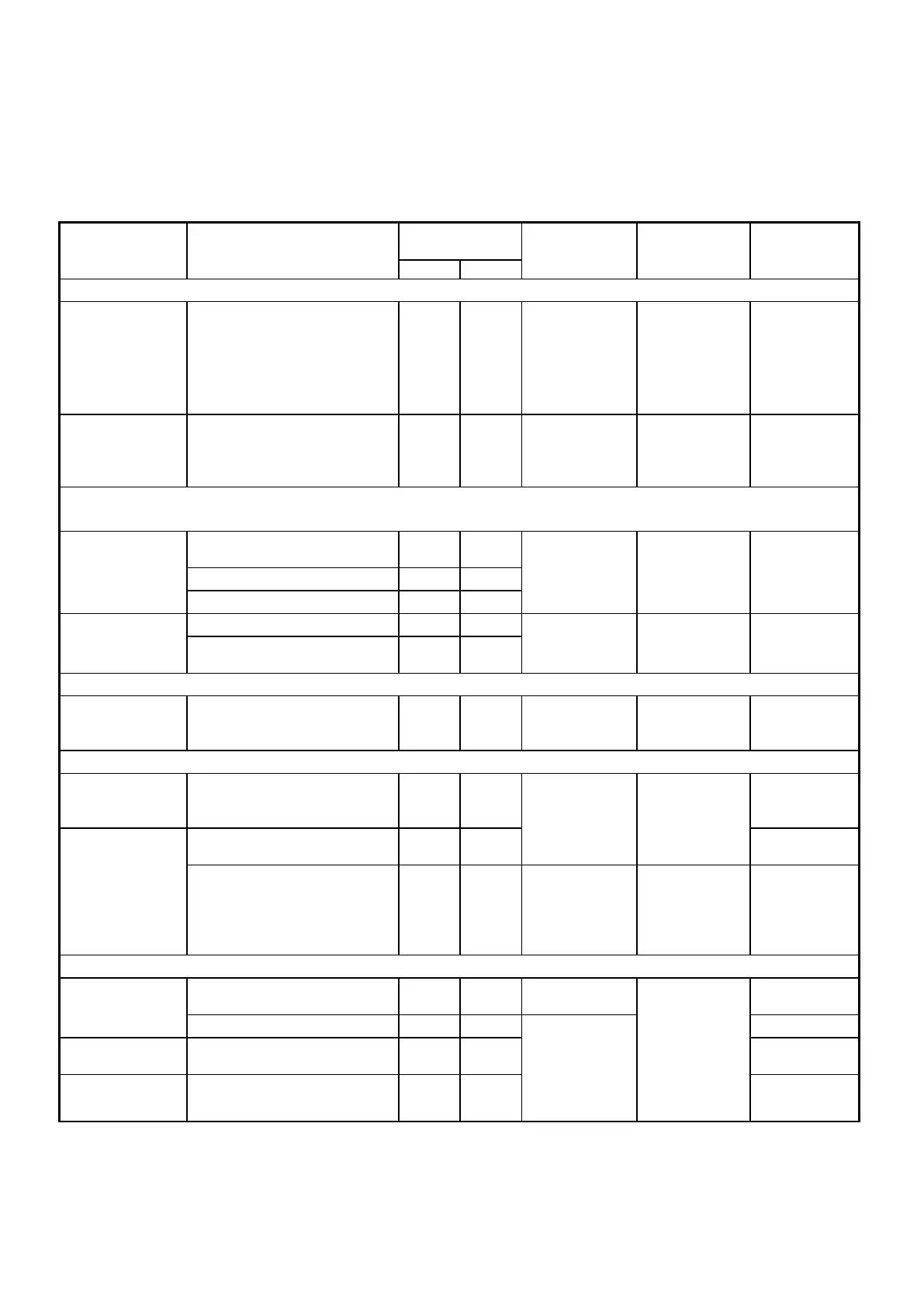

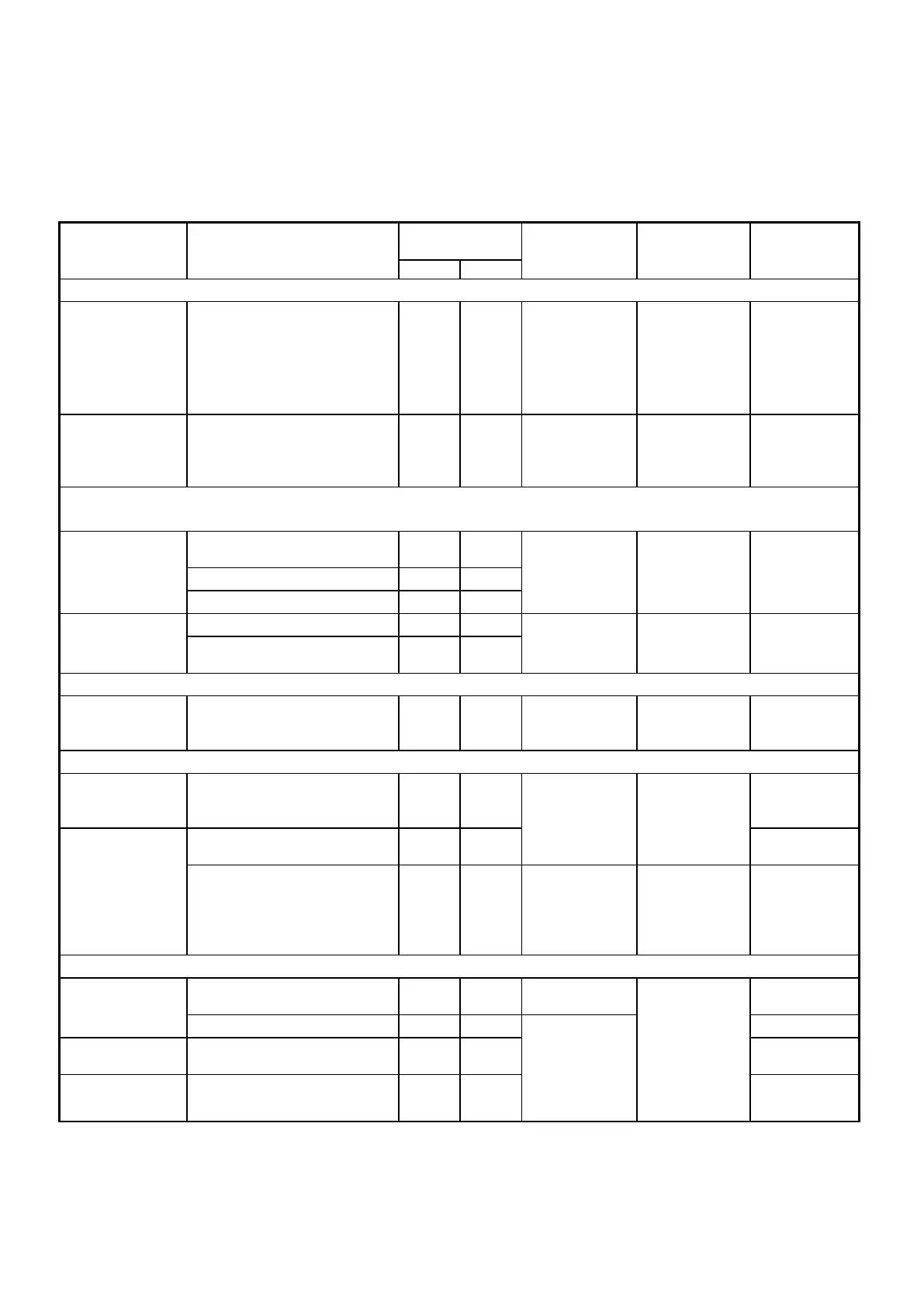

5.3 Routine and periodic inspection

To ensure stable and safe operations, check and maintain the inverter at regular intervals.

Use the checklist below to carry out inspection.

Disconnect power after approximately 5 minutes to make sure no voltage is present on the output terminals

before any inspection or maintenance.

Items Details

Methods Criteria Remedies

Environment & Ground connection

Ambient

conditions at

the installation

Confirm the temperature

and humidity at the machine

◎

Measure with

thermometer

and

hygrometer

-10 ~40°C

(14~120°F)

Humidity:

Below

Improve the

ambient or

relocate the

drive to a

better area.

Installation

Grounding

Is the grounding resistance

correct?

◎

resistance

with a

200Vclass:

below 100Ω

Improve the

grounding if

needed.

Connection

terminals

Any loose parts or

terminals?

◎

Visual check

Check with a

screwdriver

Correct

installation

requirement

Secure

terminals and

remove rust

◎

Wiring

◎

Visual check

Correct wiring

requirement

Rectify as

necessary

Any damage to the wire

insulation?

◎

Input power

voltage

Is the voltage of the main

circuit correct?

◎

voltage with a

conform with

voltage if

Circuit boards and components

Printed circuit

board

damage to printed circuit

◎

Visual check

Correct

component

condition

replace the

Power

component

Any dust or debris

◎

Check resistance between

terminals

◎

Measure with

a multi-tester

circuit or

broken circuit

in three

Consult with

the supplier

Cooling fan

Unusual vibration and

noise?

◎

Correct

cooling

Consult with

the supplier

◎

Visual check

Heat sink Excessive dust or debris

◎

Ventilation Path

Is the ventilation path

blocked?

◎

Clear the

path

Loading...

Loading...