The revolving magnetic field is driven by the engine

at constant speed. This constant speed is maintained

by a mechanical engine governor. Units with a 2-pole

rotor require an operation speed of 3600 rpm to deliv-

er a 60 Hertz AC output.

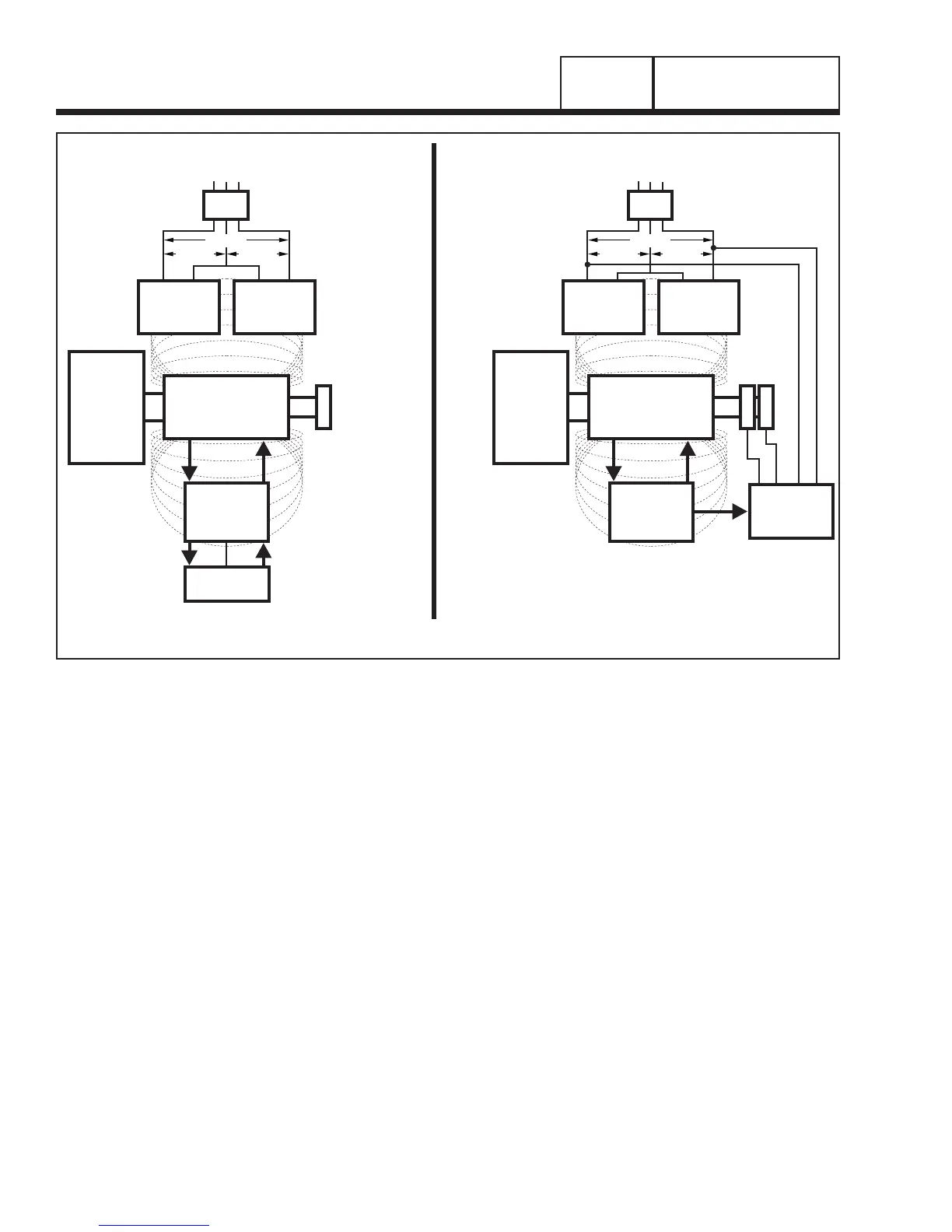

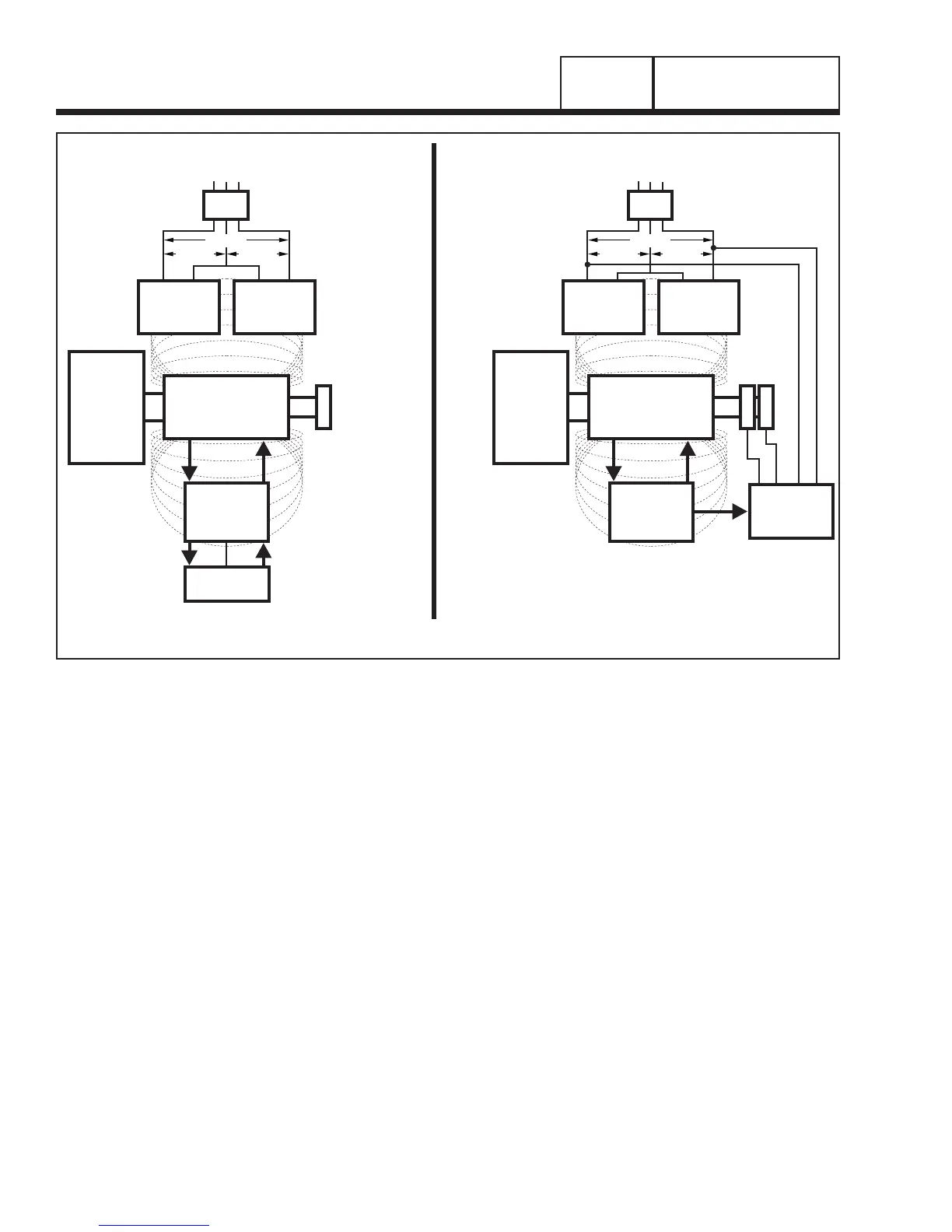

Generator operation may be described briefly as follows.

1. Some “residual” magnetism is normally present in the

Rotor, which is sufficient to induce approximately 1 to 2

Volts AC in to the Stator’s AC Power Windings and DPE

winding.

2. See Figure 8.

A. During startup, the “residual” voltage that

is induced into the DPE winding will initially

charge the capacitor to a greater potential.

When the capacitor is discharged the voltage

is in turn induced back into the Rotor which will

exponen tially raise the voltage to 120/240.

B. During startup, the “residual” voltage that is

induced into the DPE winding will turn on the

voltage regulator allowing DC excitation current

to be delivered to the rotor and raise the voltage

to 120/240.

PART 1

Page 12

GENERAL INFORMATION

SECTION 1.1

GENERATOR FUNDAMENTALS

CAPACITOR

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE -

DIRECT

DRIVE

AUTOMATIC

VOLTAGE

REGULATOR

+-

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

SENSING

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE -

DIRECT

DRIVE

120 VAC 120 VAC

240 VAC

120 VAC 120 VAC

240 VAC

A B

CAPACITIVE DISCHARGE DIRECT EXCITATION

Figure 8. Generator Operating Diagram

Loading...

Loading...