SECTION 3.3

DIAGNOSTIC TESTS

Page 47

• Waterinfuel.

• Intakevalvestuckopen.

• Needle/floatstuckopen.

If the spark plug is dry look for the following:

• Leakingcarburetormountinggaskets.

• Intakevalvestuckclosed.

• Inoperativefuelpump.

• Pluggedfuelfilter(s).

• Varnishedcarburetor

If the engine starts hard or will not start, look for the

following:

• Physical damage to the AC generator. Check the

Rotor for contact with the Stator.

• Startingunderload.Makesureallloadsarediscon-

nected or turned off before attempting to crank and

start the engine.

• Checkthatthechokeisworkingproperly.

1. Remove fuel line at carburetor and ensure that there is

an adequate amount of fuel entering the carburetor.

2. Remove the float bowl and check to see if there is any

foreign matter in bottom of carburetor bowl.

3. The float is plastic and can be removed for access to the

needle so it can be cleaned.

4. With all of this removed, carburetor cleaner can be used

to clean the rest of the carburetor before reassembly.

5. After cleaning the carburetor with an approved carbure-

tor cleaner, blow dry with compressed air and reas-

semble.

Shelf life on gasoline is 30 days. Proper procedures

need to be taken for carburetors so that the fuel doesn’t

varnish over time. A fuel stabilizer must be used at all

times in order to ensure that the fuel is fresh at all times.

RESULTS:

If carburetor is varnished, clean or replace. Refer to

back to Flow Chart.

TEST 30 – CHOKE TEST

PROCEDURE:

If the generator is surging it may have a carburetion

problem. A lean condition can cause erratic RPM.

Slowly pull the choke out to see if surging stops. If it

does stop, carburetion should be checked.

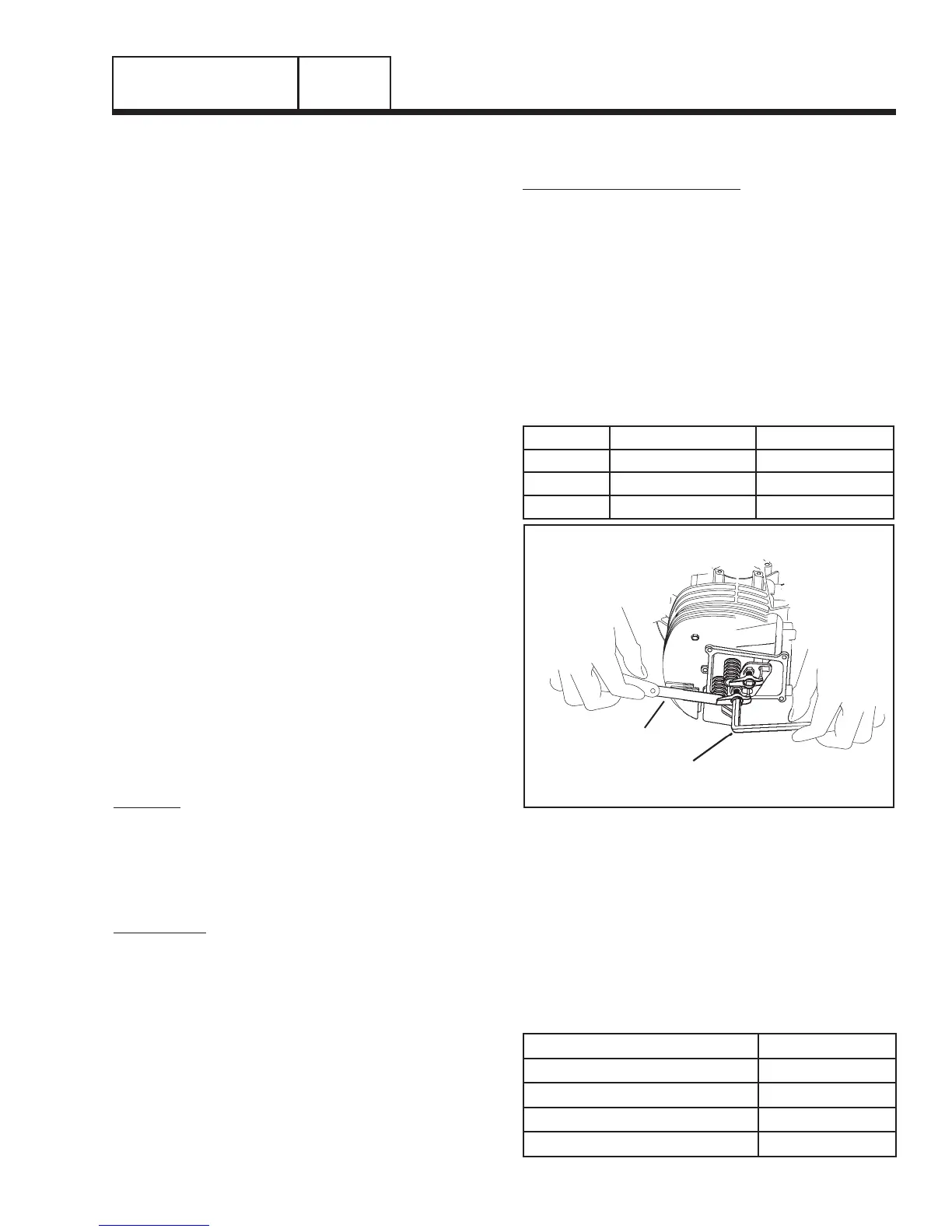

TEST 33 – CHECK VALVE ADJUSTMENT

ADJUSTING VALVE CLEARANCE:

Improperly adjusted valves can cause various engine

related problems including, but not limited to, hard starting,

rough running and lack of power.

Adjust valve clearance with the engine at room tem-

perature. The piston should be at top dead center

(TDC) of its compression stroke (both valves closed).

An alternative method is to turn the engine over and

position the intake valve fully open (intake valve spring

compressed) and adjust the exhaust valve clearance.

Turn the engine over and position the exhaust valve

fully open (exhaust valve spring compressed) and

adjust the intake valve clearance.

Correct valve clearance is given below.

Engine Intake Valve Exhaust Valve

189/206cc

0.0039 inch 0.0059 inch

389cc

0.006 ±0.0008 inch 0.006 ±0.0008 inch

410cc

0.003-0.005 inch 0.003-0.005 inch

Figure 14. Adjusting Valve Clearance

1. Loosen the rocker arm jam nut. Turn the pivot ball stud

while checking the clearance between the rocker arm

and valve stem with a feeler gauge (see Figure 14).

2. When clearance is correct, hold the pivot ball stud with

the allen wrench and tighten the rocker arm jam nut to

the specified torque with a crow's foot. After tightening

the jam nut, recheck valve clearance to make sure it did

not change.

Rocker Arm Jam Nut ft-lbs

189cc 7.48

206cc 7.48

389cc 9-12

410cc 14.01

DC CONTROL

PART 3

Loading...

Loading...