Page 46

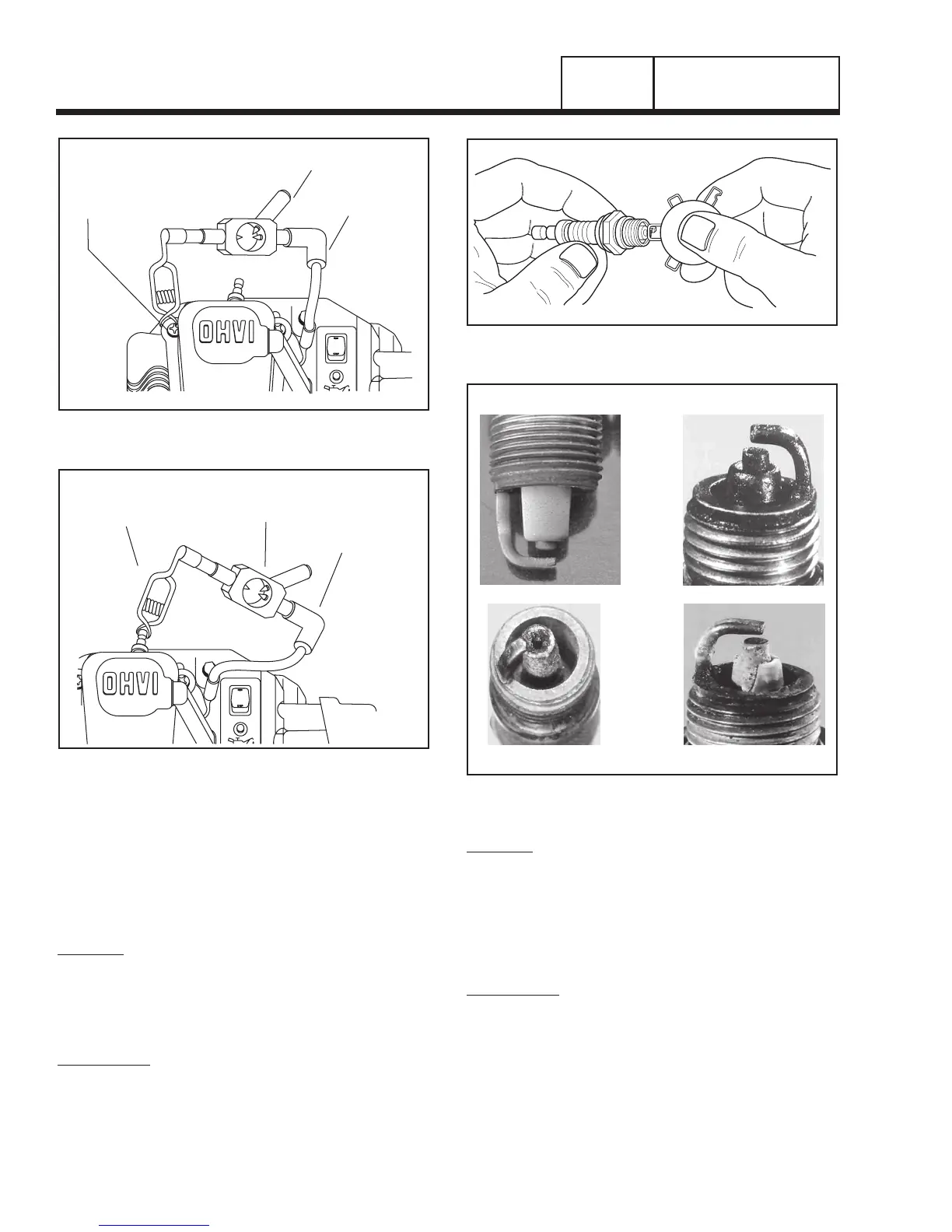

SPARK TESTER CLAMP

GROUNDED TO

CYLINDER HEAD

SPARK TESTER

SPARK PLUG

BOOT

Figure 10. Testing Ignition System

SPARK TESTER CLAMP

CONNECTED TO

SPARK PLUG

SPARK TESTER

SPARK PLUG

BOOT

Figure 11. Checking Engine Miss

4. Crank the engine rapidly. Engine must be cranking at

350 rpm or more. If spark jumps the tester gap, you may

assume the ignition system is working properly. Repeat

on remaining cylinder spark plug.

5. If spark jumps the tester gap intermittently, the problem

may be in the Ignition Magneto.

RESULTS:

Refer back to the Flow Chart

TEST 26 – CHECK SPARK PLUGS

PROCEDURE:

Remove spark plugs. Clean with a commercial solvent.

DO NOT BLAST CLEAN SPARK PLUGS. Replace

spark plugs if badly fouled, if ceramic is cracked, or

if badly worn or damaged. Refer to specifications in

the front of this manual for proper replacement spark

plugs and spark plug gaps.

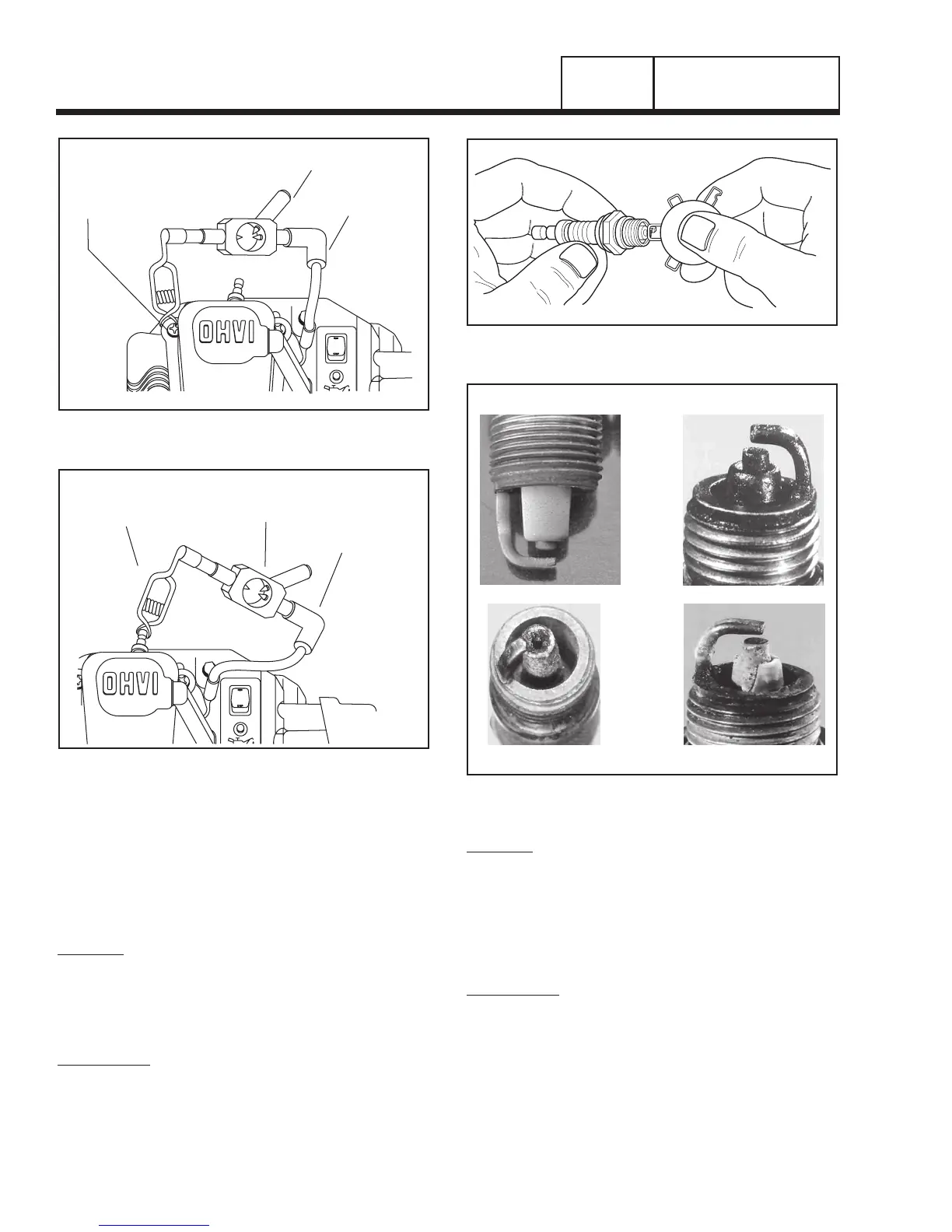

Figure 12. Setting Spark Plug Gap

NORMAL MISFIRES

PRE-IGNITION DETONATION

Figure 13. Spark Plug Conditions

RESULTS:

1. Clean and regap or replace sparks plug as necessary.

2. Refer back to the Flow Chart.

TEST 29 – CHECK CARBURETION

PROCEDURE:

Before making a carburetion check, be sure the fuel sup-

ply tank has an ample supply of fresh, clean gasoline.

Check that all shutoff valves are open and fuel flows

freely through the fuel line.

Make sure the choke operates properly.

If the engine will not start, remove and inspect the spark

plug. If the spark plug is wet, look for the following:

• Overchoking.

• Excessivelyrichfuelmixture.

PART 3

DC CONTROL

SECTION 3.3

DIAGNOSTIC TESTS

Loading...

Loading...