INTRODUCTION

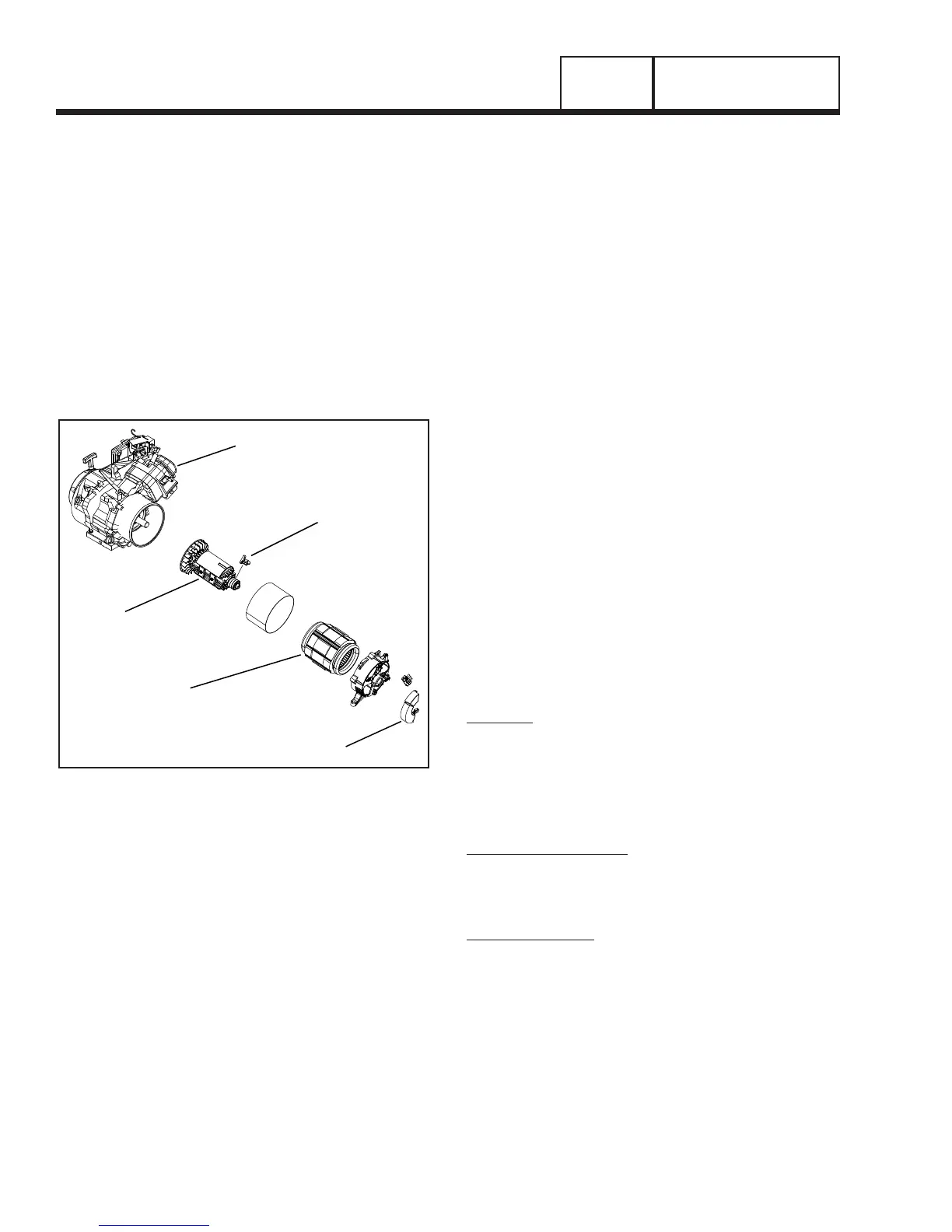

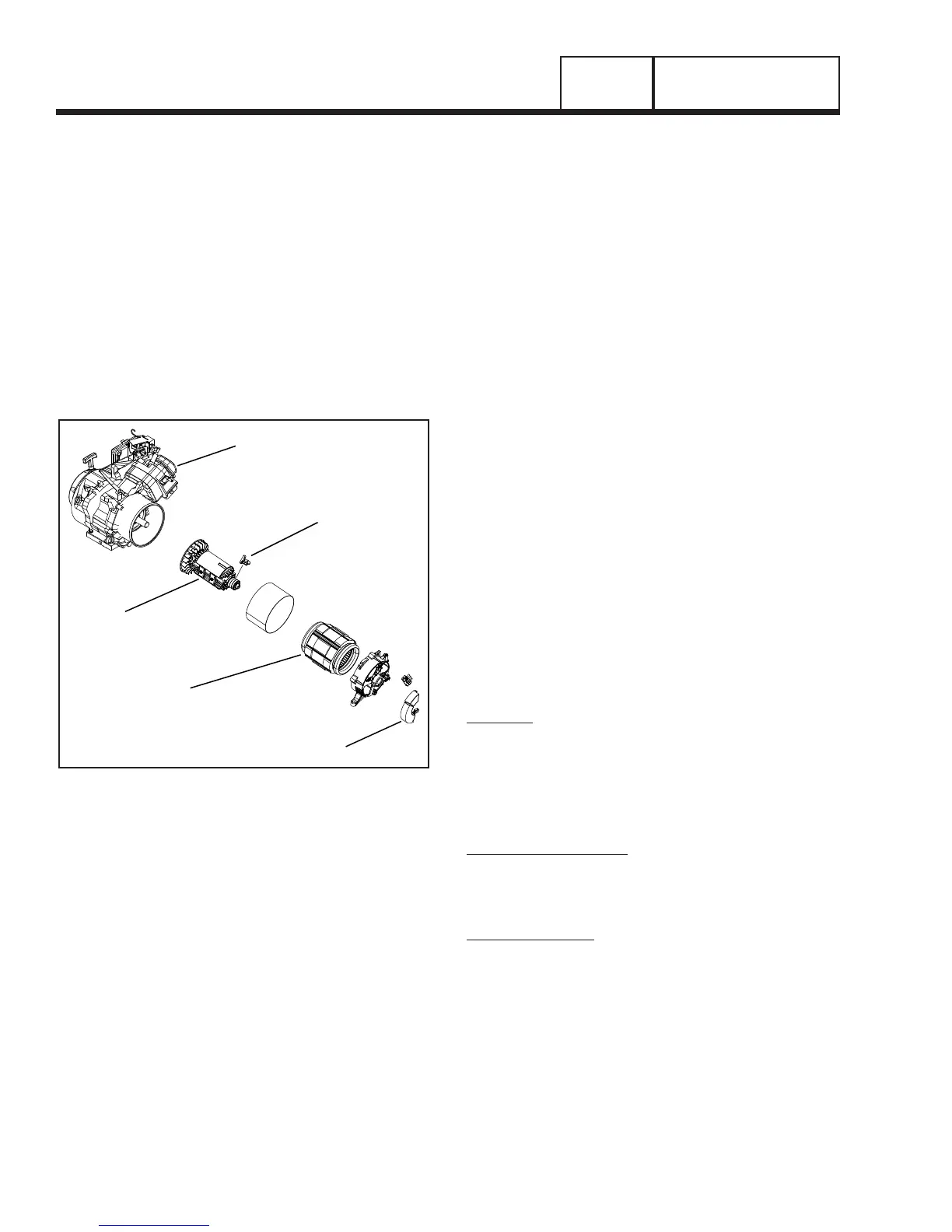

A typical brushed type portable generator will need 4

major components to function: a prime mover, a sta-

tor, a rotor, and a voltage regulator.

As the engine starts to crank, residual magnetism

from the rotor creates magnetic lines of flux. The lines

begin to cut the excitation winding and induce a small

voltage into the voltage regulator. The excitation volt-

age will power the voltage regulator and the voltage

regulator will start to sense AC voltage from Wires

S15 and S16. The lower voltage from the sensing

wires will cause DC excitation to the rotor to be driven

up until AC output is at desired level of 240VAC. Once

the generator has reached 240VAC it will maintain the

DC voltage, regulating the alternator when loads are

applied and removed.

STATOR

ROTOR

ENGINE

BRUSHES

VOLTAGE REGULATOR

Figure 1. AC Generator Exploded View

STATOR ASSEMBLY

The stator has three windings wound separately

inside the can. Two are the power windings and are

located on Wire 44 (Hot) and Wire 33 (Neutral); the

other winding is located on Wire 11 (Hot) and Wire 22

(neutral). The third winding is called DPE winding or

Displaced Phase Excitation winding and is located on

Wire 2 and Wire 6.

BRUSH HOLDER AND BRUSHES

The brush holder is retained to the rear bearing car-

rier by means of two Taptite screws. A positive (+) and

a negative (-) brush are retained in the brush holder.

Wire 4 connects to the positive (+) brush and Wire

0 to the negative (-) brush. Rectified and regulated

excitation current are delivered to the rotor windings

via Wire 4, and the positive (+) brush and slip ring.

The excitation current passes through the windings

to the negative (-) slip ring and brush on Wire 0. This

current flow creates a magnetic field around the rotor

having a flux concentration that is proportional to the

amount of current flow.

ROTOR RESIDUAL MAGNETISM

The generator revolving field (rotor) may be consid-

ered to be a permanent magnet. Some “residual”

magnetism is always present in the rotor. This residu-

al magnetism is sufficient to induce a voltage into the

stator AC power windings that is approximately 2-5

volts AC.

Note: Some Rotors have a magnet placed inside

to help excite the rotor after it has been left idle

for a long period of time.

VOLTAGE REGULATOR

Refer to Figure 3 for the proper identification of the

voltage regulator. Unregulated AC output from the

stator excitation winding is delivered to the regulator’s

DPE terminals, via Wire 2 and Wire 6. The voltage

regulator rectifies that current and, based on stator

AC power winding sensing, regulates it. The rectified

and regulated excitation current is then delivered to

the rotor windings from the positive (+) and negative

(-) regulator terminals, via Wire 4 and Wire 0. Stator

AC power winding “sensing” is delivered to the regula-

tor via Wires S15 and S16.

OPERATION

STARTUP:

When the engine is started, residual magnetism from

the rotor induces a voltage into (a) the stator AC

power windings, (b) the stator excitation or DPE wind-

ings. In an “on-speed” (engine cranking) condition,

residual magnetism is capable of creating approxi-

mately one to three volts AC.

ON-SPEED OPERATION:

As the engine accelerates, the voltage that is induced

into the stator windings increases rapidly, due to the

increasing speed at which the rotor operates.

FIELD EXCITATION:

An AC voltage is induced into the stator excitation

(DPE) windings. The DPE winding circuit is com-

pleted to the voltage regulator, via Wire 2 and Wire

6. Unregulated alternating current can flow from the

winding to the regulator. The voltage regulator “sens-

es” AC power winding output voltage and frequency

via stator Wires S15 and S16.

The regulator changes the AC from the excitation

winding to DC. In addition, based on the Wire S15

and Wire S16 sensing signals, it regulates the flow of

direct current to the rotor. The rectified and regulated

current flow from the regulator is delivered to the rotor

windings, via Wire 4, and the positive brush and slip

ring. This excitation current flows through the rotor

PART 1

Page 18

GENERAL INFORMATION

Section 1.4

BRUSHED EXCITATION SYSTEM

Loading...

Loading...