AC GENERATORS

SECTION 2.3

AC DIAGNOSTIC TESTS

TEST 6 – CHECK CAPACITOR

DISCUSSION:

The brushless rotor system relies on the charging and

discharging of a capacitor to induce voltage into the

rotor and also to regulate voltage once 240 VAC is

achieved. If the capacitor fails, only residual magne-

tism of the rotor will be measured at the Main Breaker.

*

Warning: The capacitor may need to be dis-

charged before testing. A capacitor can be

discharged by crossing the terminals with a

metal insulated screw driver.

*

Warning: Use proper protective equipment

when dealing with a capacitor that has

exploded.

PROCEDURE:

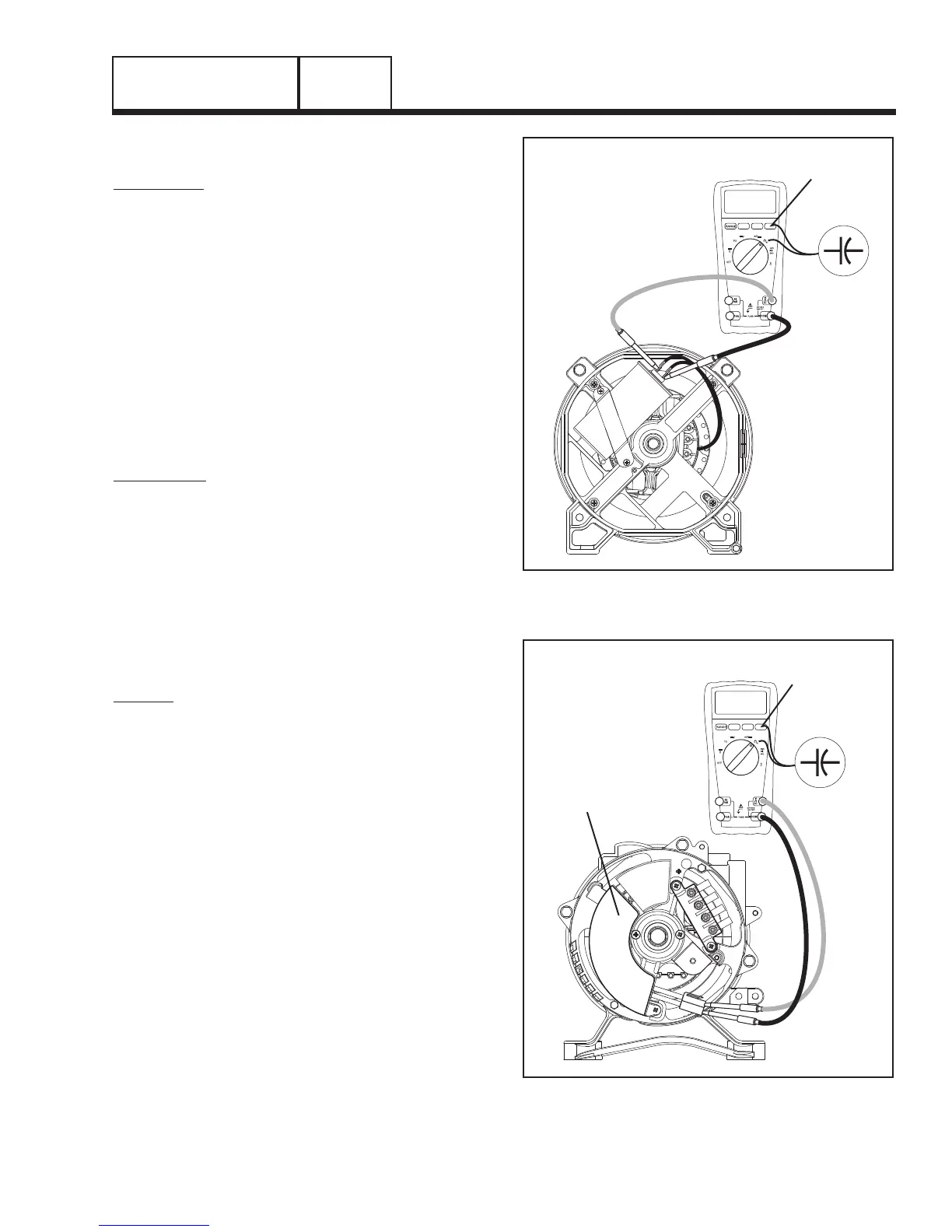

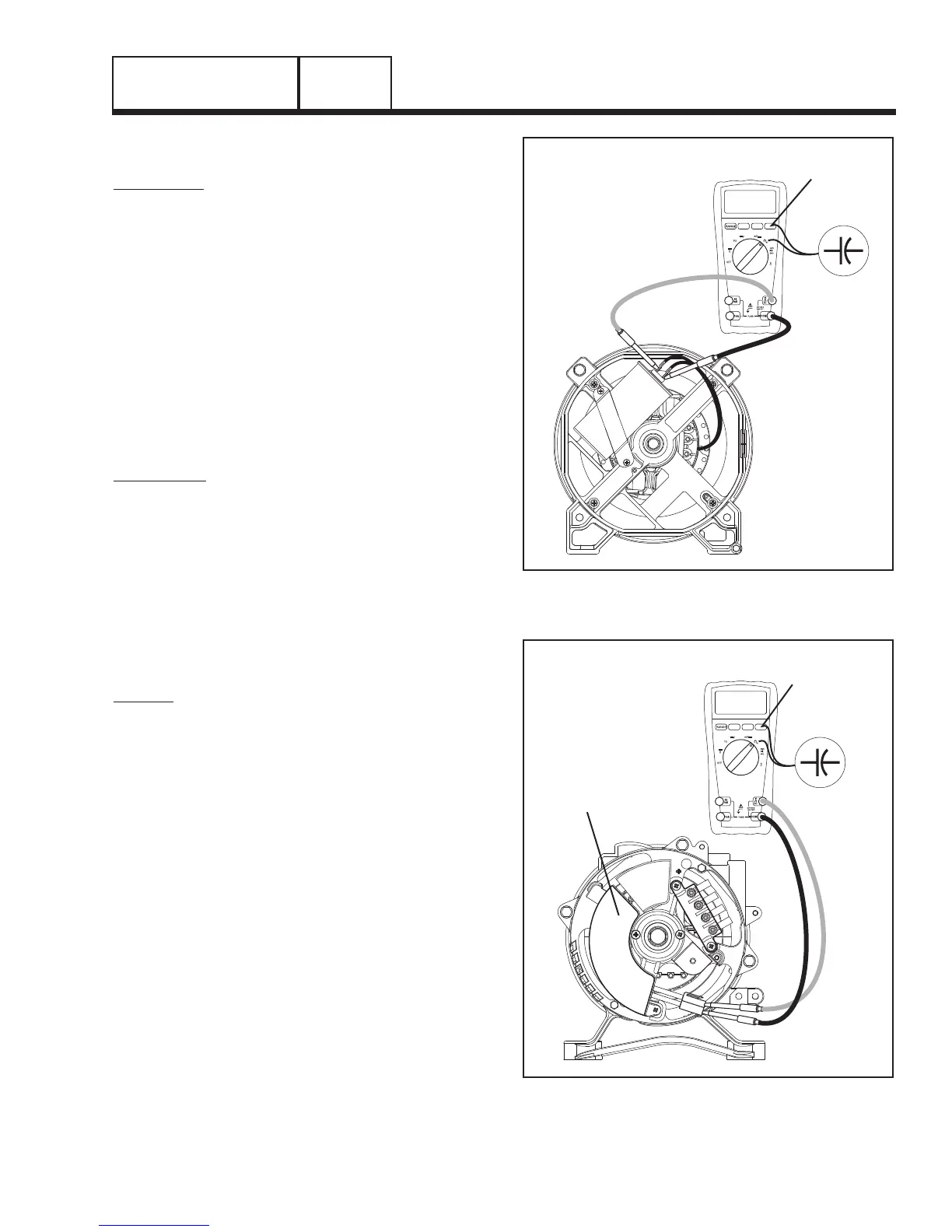

1. Consult the owner’s manual of the meter being used for

directions on measuring capacitance. Figures 7 and 8

show a typical meter and how to check capacitance.

2. Connect the meter leads directly across the terminals of

the capacitor. The rated µf (micro farad) of the capacitor

is marked on the side of the canister.

3. The meter should display the correct µf reading ± 5µf.

If anything other than the indicated rating is displayed,

replace the capacitor.

RESULTS:

1. Refer back to flow chart

2. Common observations can be made by visually inspect-

ing the capacitor.

a. A capacitor that has gone bad can have a ten-

dency to explode. Use caution when dealing

with an exploded capacitor, the gel from inside

a capacitor can cause skin irritation.

b. A capacitor is defective if the terminal connec-

tions are loose on the canister.

c. A capacitor is defective if it wobbles while sitting

on a flat surface.

d. If any of the above observations are observed,

replace the capacitor.

SET TO READ

CAPACITANCE

59.0

µf

Figure 7. Capacitor Test Points

(Alternator Configuration “A”)

SET TO READ

CAPACITANCE

28.0

µf

CAPACITOR 28µf

Figure 8. Capacitor Test Points

(Alternator Configuration “B”)

PART 2

Page 29

Loading...

Loading...