AC GENERATORS

SECTION 2.3

AC DIAGNOSTIC TESTS

TEST 9 – TEST BRUSHED STATOR WINDINGS

DISCUSSION:

Most brushed stators have three main windings that

are needed to produce voltage. The alternator has

two main power windings that supply power to the

load and a DPE winding to provide excitation voltage

to the rotor. It is important that these windings remain

isolated from ground or the chassis of the alternator.

PROCEDURE:

1. Isolate all stator wires from the control panel and the

voltage regulator.

2. Set a VOM to measure resistance.

3. Refer to Configuration “C” in Section 1.4 for proper test

points for checking the stator. Every connection needs to

be checked coming out of the stator for a short to ground.

RESULTS:

1. If any wire has a direct short to ground or to the chassis

of the alternator replace the alternator assembly.

2. If all wires test good for a short to ground, refer back to

flow chart.

TEST 10 – CHECK LOAD VOLTAGE &

FREQUENCY

PROCEDURE:

Perform this test in the same manner as Test 1, but

apply a load to the generator equal to its rated capacity.

With load applied check voltage and frequency.

Frequency should not drop below about 59 Hertz with

the load applied.

Voltage should not drop below about 220 VAC nor rise

above 265 VAC with load applied.

RESULTS:

1. If voltage and/or frequency drop excessively when the

load is applied, refer back to flow chart.

2. If load voltage and frequency are within limits, end tests.

TEST 11 – CHECK LOAD WATTS & AMPERAGE

PROCEDURE:

Add up the wattages or amperages of all loads pow-

ered by the generator at one time. If desired, a clamp-

on ammeter may be used to measure current flow.

See “Measuring Current” in Section 1.2.

A Wattage Reference Guide is provided on the next

page to assist in determining how many items the

generator can operate at one time.

NOTE: All figures are approximate. See data label

on appliance for wattage requirements.

RESULTS:

1. If the unit is overloaded, reduce the load.

2. If load is within limits, but frequency and voltage still drop

excessively, refer back to Flow Chart.

Overloading a generator in excess of its rated wattage

capacity can result in damage to the generator and to

connected electrical devices. Observe the following to

prevent overloading the unit:

• Addupthetotalwattageof allelectricaldevicesto

be connected at one time. This total should NOT be

greater than the generator's wattage capacity.

• Theratedwattageoflightscanbetakenfromlight

bulbs. The rated wattage of tools, appliances and

motors can usually be found on a data label or

decal affixed to the device.

• If the appliance, tool or motor does not give watt-

age, multiply volts times ampere rating to determine

watts (volts x amps = watts).

• Some electric motors, such as induction types,

require about three times more watts of power for

starting than for running. This surge of power lasts

only a few seconds when starting such motors.

Make sure to allow for high starting wattage when

selecting electrical devices to connect to the generator:

1. Figure the watts needed to start the largest motor.

2. Add to that figure the running watts of all other con-

nected loads.

TEST 12 – ADJUST VOLTAGE REGULATOR

PROCEDURE:

1. Remove cover from end of alternator assembly.

2. Remove two screws holding down the voltage regulator

(AVR); refer to Figure C in Section 1.4 for identification.

3. Leave AVR connected to stator and brushes

4. Set VOM to measure AC voltage.

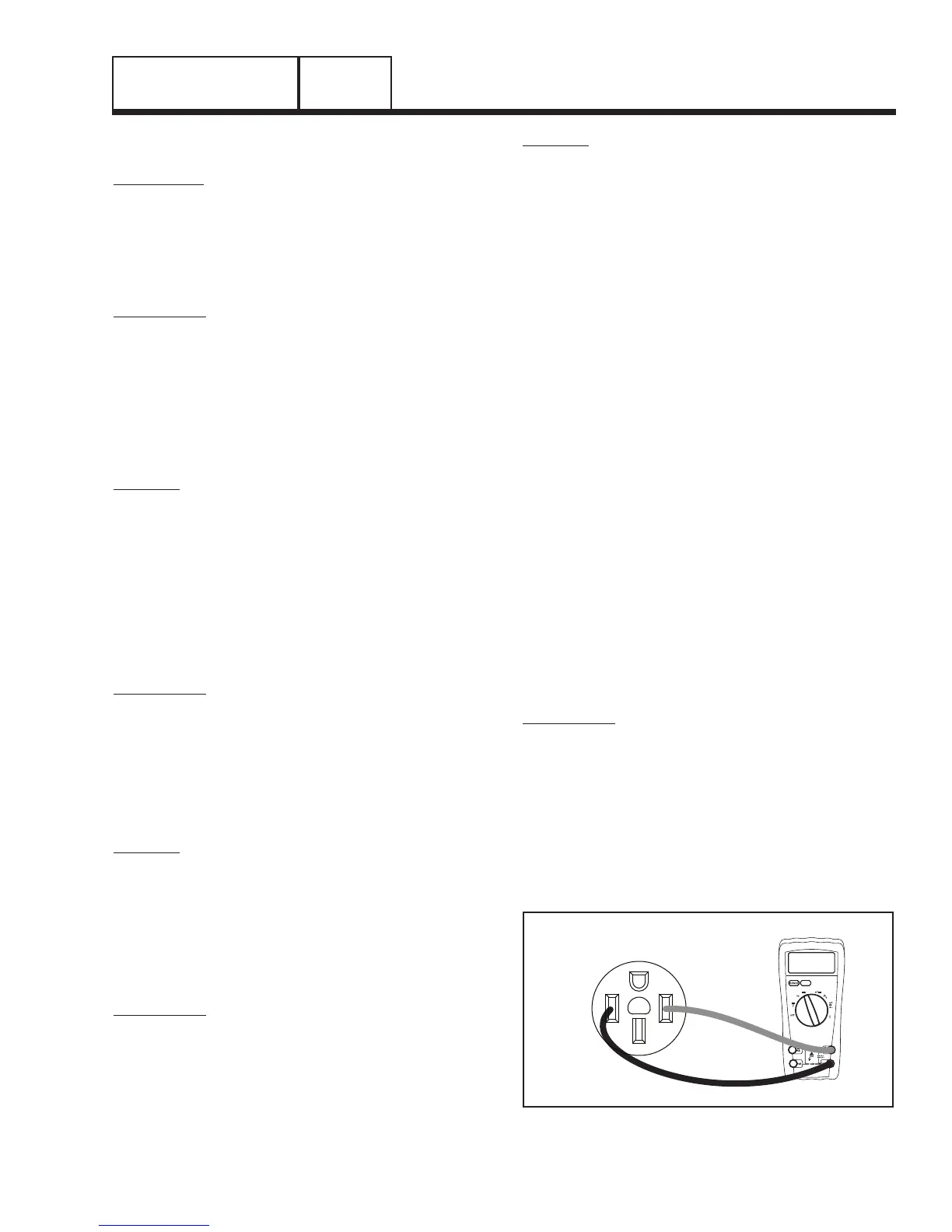

5. Connect VOM across a 240VAC socket as shown in

Figure 9.

Figure 9. VOM Test Leads Connected to a 240 VAC

receptacle

PART 2

Page 31

Loading...

Loading...