Section 1 EFI Engine Control Diagnostic Tests

18 Diagnostic Repair Manual

Air Metering and Measurement

The amount of air entering the engine is controlled by a

conventional butterfly valve located in a throttle body

assembly.

Airflow measurement is by Speed Density. The speed

density system uses a solid-state pressure transducer to

measure the pressure in the intake, combined with rpm

and air temperature to indirectly determine airflow. A

certain pressure relates to a certain voltage which is

relayed to the ECU (Engine Control Unit).

Sensor Inputs

As with most EFI systems, there are 6 basic inputs that

are measured by the ECU;

RPM

Most systems measure rpm using the ignition coil pulse or

crank triggered magnetic/hall effect sensors. Rpm is

considered a primary input signal on all EFI systems. Many

systems generate an injection pulse for every tachometer

pulse, so as rpm is increased, the frequency of injection

pulses increases. However, since generator rpm is

constant, this input is primarily for governing engine speed.

Airflow

On many systems, this input is also considered a primary

input signal. However, in portable generator applications,

airflow is predetermined and calculated by algorithms in

the ECU.

Manifold Pressure

On speed density type systems, this input is essential

when combined with the rpm signal to calculate airflow.

As the throttle is opened, the manifold pressure

increases which will require more fuel.

Throttle Position

This input is a secondary input on most systems. It is

required mainly for load enrichment when the throttle is

rapidly opened. However, a Throttle Position Sensor

(TPS) is not utilized on this portable generator

application.

Engine Temperature

Engine temperature is a secondary input required mainly

to ensure proper starting and warm-up of the engine.

When the engine is cold, the air to fuel ratio must be very

rich to enable enough fuel to vaporize for proper starting.

The computer increases the injector pulse width to

supply extra fuel when cold and tapers this fuel off as the

cylinder head temperature increases. Once the engine

warms past 120 degrees or so, the computer does not

need to add any extra fuel.

Where a carburetor chokes off air to enrich the mixture

when cold, EFI injects extra fuel to achieve the same effect.

Air Temperature

This is a secondary input required especially on speed

density systems. The sensor is usually mounted in the

intake manifold or air filter area. As the air temperature

drops, its density increases. Denser air requires more

fuel. As the temperature of the inducted air increases, the

computer reduces the pulse width to compensate for

lower density.

Basic Operation

As explained in Basic Open-Loop Theory, the computer

processes all of the voltage signals from the various

sensors to determine the engine operating conditions at

the moment and delivers the appropriate pulse width to

the injector. If engine airflow increases by 10%, the pulse

width is also increased by about 10% to keep the air/fuel

ratio constant. For example, if the load is doubled from

2000 Watts to 4000 Watts, the number of injections are

also doubled to double the fuel flow.

The computer looks at the changes in sensor inputs

every few milliseconds in order to be ready to modify the

pulse width if any of the parameters change.

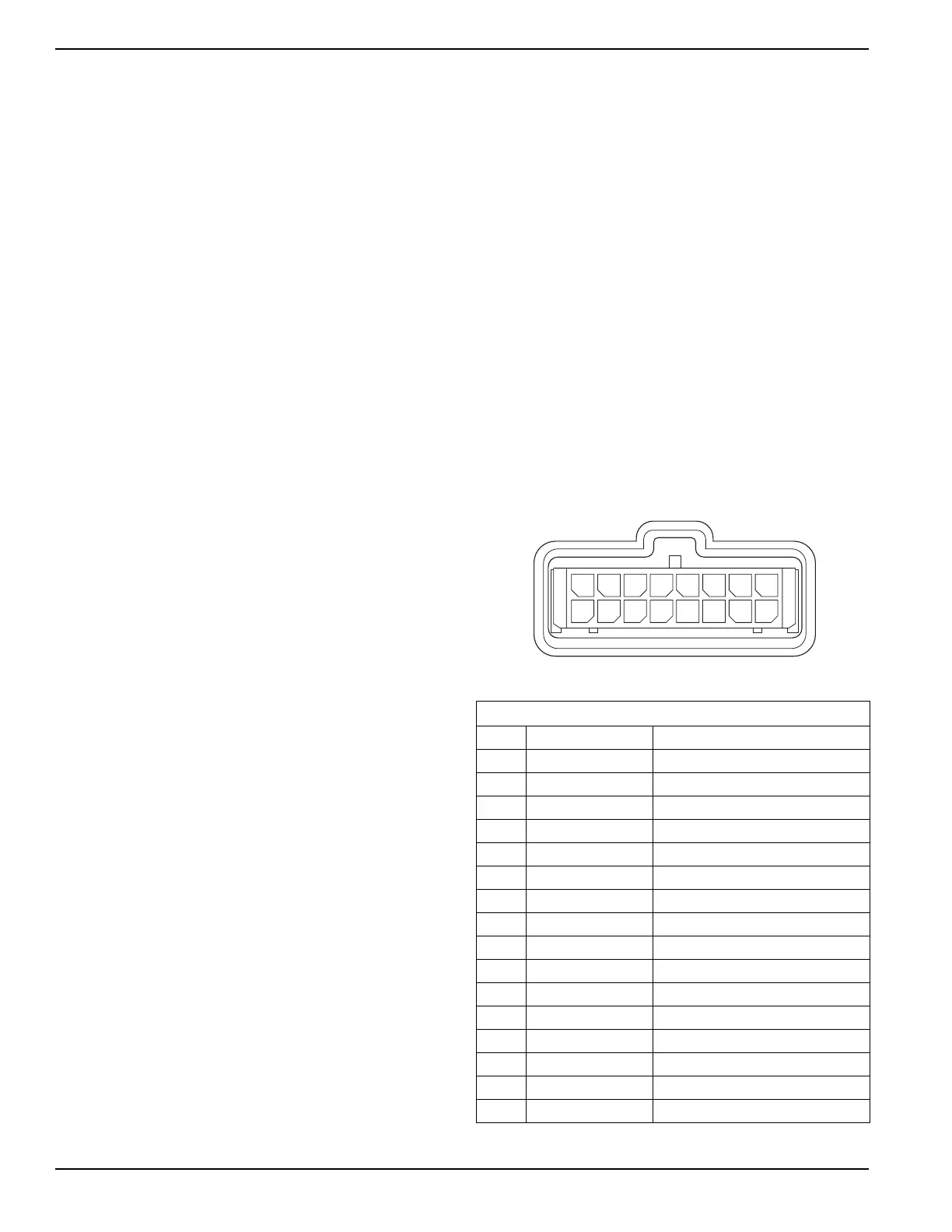

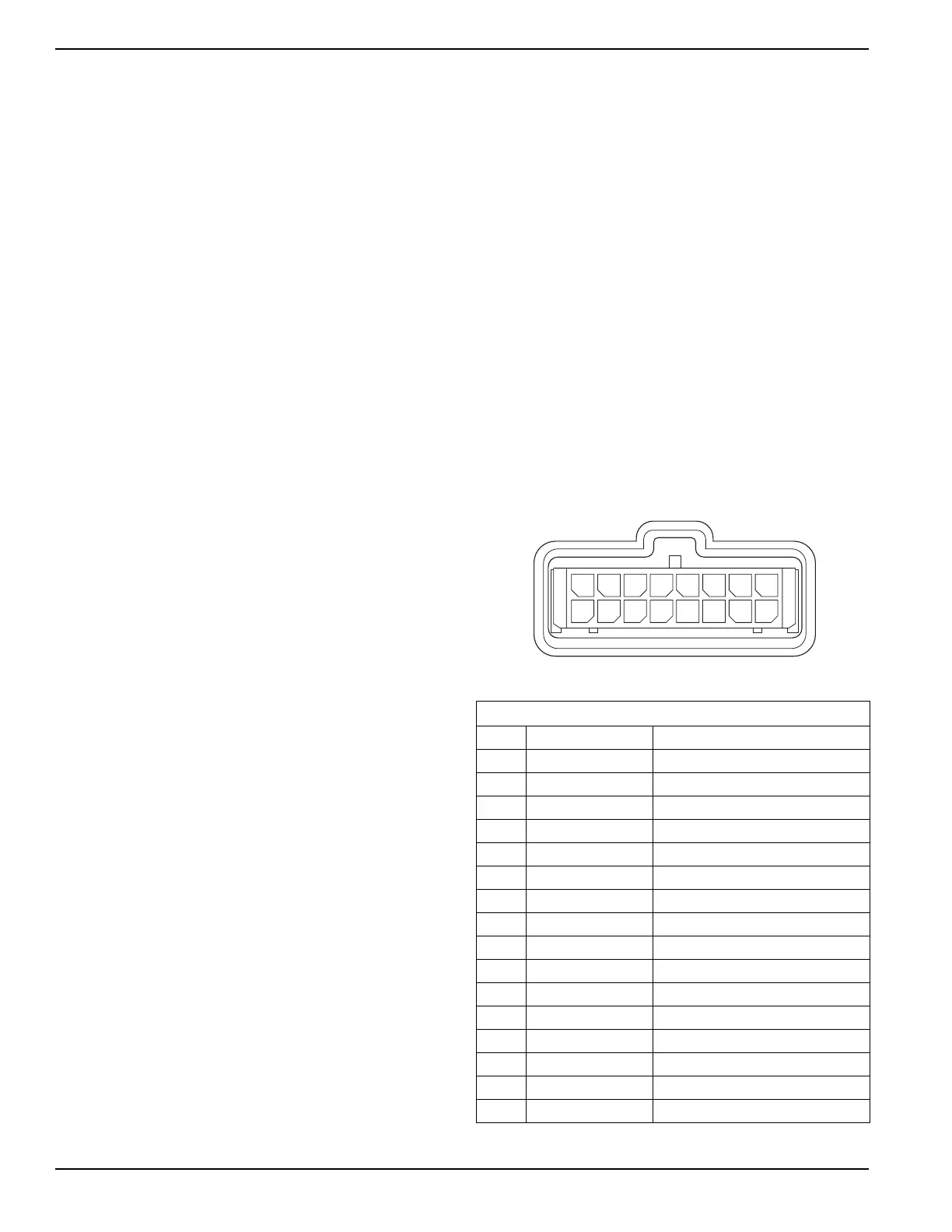

Figure 4-2. ECU/Carburetor Connector

Table 1-1. ECU/Carburetor Connector

Pin Wire Color Function

1N/A N/A

2N/A N/A

3 Black Oil Pressure

4 Brown Temperature

5 Green/White CT (Current Txfmr)

6 Grey Idle Switch

7 Red Battery + (POS)

8 Green/White CT (Current Txfmr)

9 Yellow/Green Battery – (GND)

10 Red/White Key Switch

11 Blue/White Crankshaft Sensor

12 Yellow Warning Lamp

13 White Injector

14 Green Communication

15 Orange Fuel Pump

16 Red/Black Ignition

16 8

71

4

5

6

3

12

15

14

13 911

10 2

Loading...

Loading...