Section 5 Engine Diagnostic Tests

Diagnostic Repair Manual 35

Test 30 – Check / Adjust Governor

(220/410/530cc Non-EFI Engine)

The generator AC frequency output is directly

proportional to the speed of the rotor. A two-pole rotor

(having a single north and a single south magnetic pole)

will produce an AC frequency of 60 hertz at 3600 RPM.

The AC output voltage is generally proportional to AC

frequency. A low or high governor speed will result in a

correspondingly low or high AC frequency and voltage

output. The governed speed must be adjusted before any

attempt to adjust the voltage regulator is made.

Procedure

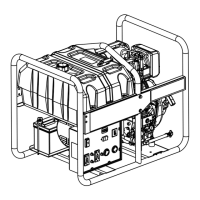

See Figure 5-21.

1. Loosen governor clamp bolt (A).

2. Hold governor lever (B) at its wide open throttle

position, and rotate governor shaft (C) clockwise as

far as it will go. Tighten governor lever clamp bolt

to 70 in-lbs (8 Nm).

3. Start generator and let stabilize and warm up at no-

load.

Figure 5-21. Governor Adjustment (410 Engine)

4. Connect a frequency meter across generator AC

output leads.

5. Turn primary adjust screw (D) to obtain a frequency

reading of 62.5 Hz.

6. When frequency is correct at no load, check AC

voltage reading. If voltage is incorrect, the voltage

regulator may require adjustment (if equipped).

Results

1. If after adjusting engine governor, frequency and

voltage are good, discontinue tests.

2. If frequency is good but voltage is high or low, refer

to flow chart.

3. If engine was overspeeding, check linkage and

throttle for binding. If no governor response is

indicated, refer to engine service manual.

Test 31 – Check Oil Pressure Switch

If engine cranks and starts, then shuts down almost

immediately, check the following:

• Low engine oil level.

• Low oil pressure.

• Defective oil pressure switch.

Figure 5-22. Low Oil Pressure Switch

Procedure

1. Check engine crankcase oil level.

a. Check engine oil level.

b. If necessary, add recommended oil to di

pstick

FULL

mark. DO NOT OVERFILL

ABOVE

FULL

MARK.

2. Do the following:

a. Disconnect Wire 86 and Wire 0 from o

il

pressure s

witch te

rminals.

b.

Remove switch and install an oil pressu

re

ga

uge.

c. Start engine while observing oil pressure

reading on gauge.

d. Note oil pressure.

(1) Normal oil pressure is approximately 35-40

p

si with engine running. If normal oil pressure

is indicated, go to Step 4 of this test.

(2) If oil pressure is below about 10 psi, shut

engine down immediately. A problem

exists

i

n engine lubrication system. Refe

r to

Se

rvice Manual, Generac P/N 0F6923 fo

r

e

ngine service recommendations.

NOTE: The oil pressure switch is rated at 10 psi

for single cylinder engines.

3. Remove oil pressure gauge and install oil pressure

switch. Do NOT connect Wire 86 or Wire 0 to

switch terminals.

a. Set a DMM to measure resistance.

b. Connect meter test leads across switch

terminals. With engine shut down, the meter

should read CONTINUITY.

c. Crank and start engine. The meter should read

INFINITY.

Loading...

Loading...