Diagnostic Repair Manual 1

Section 1 Brushless Capacitor Excitation

Introduction

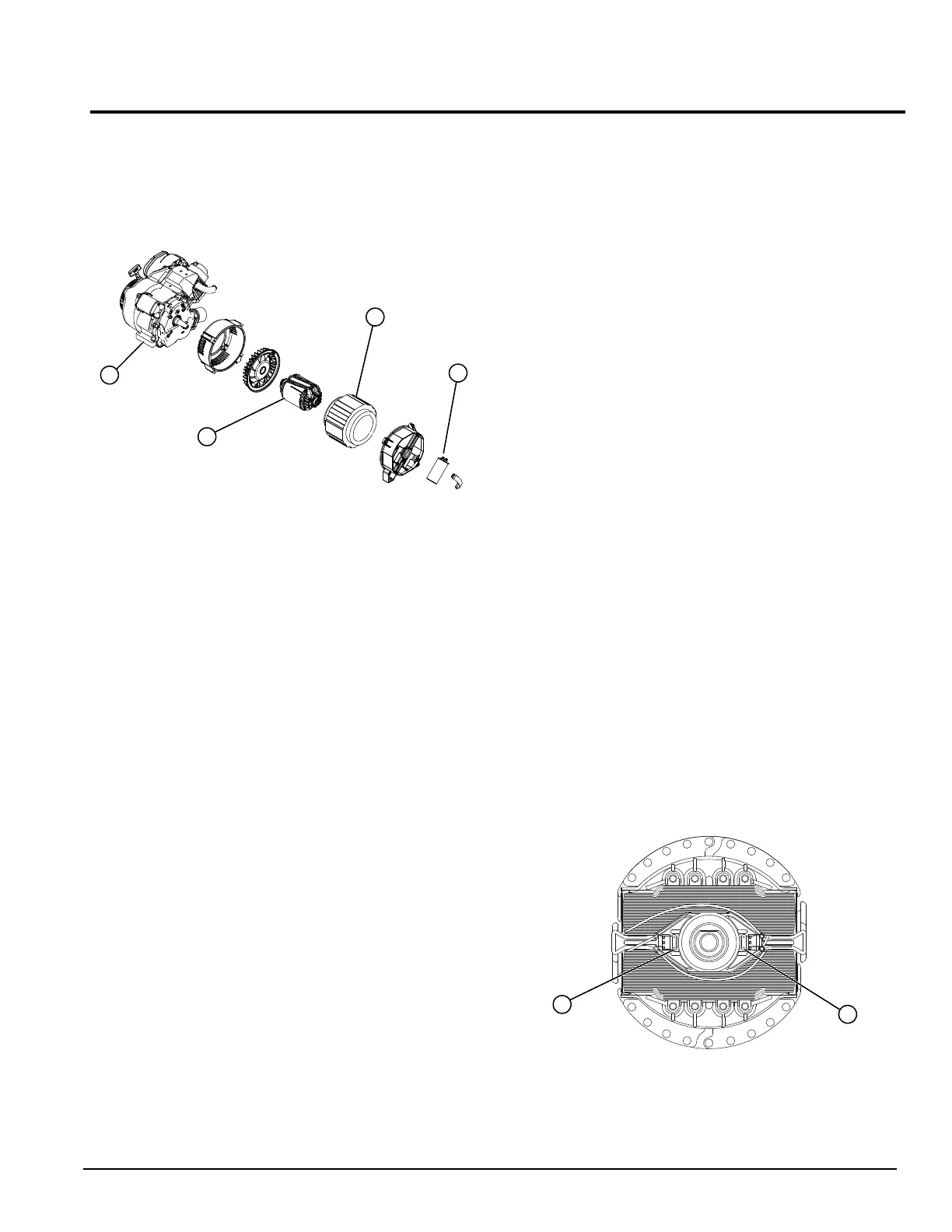

See Figure 1-1. A typical brushless type portable

generator needs 4 major components to function: a prime

mover, stator, rotor, and capacitor.

Figure 1-1. AC Generator Exploded View

As the engine begins to rotate, residual/permanent

magnetism from the rotor creates magnetic lines of flux.

The lines begin to cut the excitation winding and induce a

small voltage into the winding. The voltage causes the

capacitor to charge.

The capacitor on the excitation winding takes the place of

a voltage regulator. It will charge until AC peaks, then as

AC starts to fade it will discharge causing a voltage to be

induced into the rotor.

In one rotation of the rotor, the capacitor will charge and

discharge twice. Because it's being charged by the North

and South poles, it will induce AC voltage discharges into

the rotor.

Two diodes in the rotor convert AC voltage to DC. There

is a diode in one pole that is orientated in one direction,

and a diode in the opposite pole orientated in the

opposite direction. This produces a North and South

poled rotor.

A capacitor discharge generator will produce a lower

voltage until load is applied. Once load is applied, the

output voltage will rise due to induction into the DPE

Winding/Capacitor.

As load is applied, current in the main AC windings

increases. This increase in EMF is also induced into the

excitation winding (much like a transformer functions).

The increased EMF into the excitation winding causes

voltage to increase which also increases the charge/

discharge value of the capacitor. This creates a stronger

magnetic field in the rotor and higher AC output.

NOTE: This will only increase from no load to full load

and will stop increasing at that point.

NOTE: The voltage of a brushless capacitive discharge

generator will start low and increase as load is applied.

Stator Assembly

The stator has three windings wound separately inside

the can. Two are power windings located on Wire 44

(Hot) and Wire 33 (Neutral), the other winding is on Wire

11 (Hot) and Wire 22 (Neutral). The third winding is the

Displaced Phase Excitation (DPE) winding and is on

Wire 2 and Wire 6. Some generators have color coded

wires. Always use the appropriate schematic and wiring

diagram for unit.

Rotor Assembly

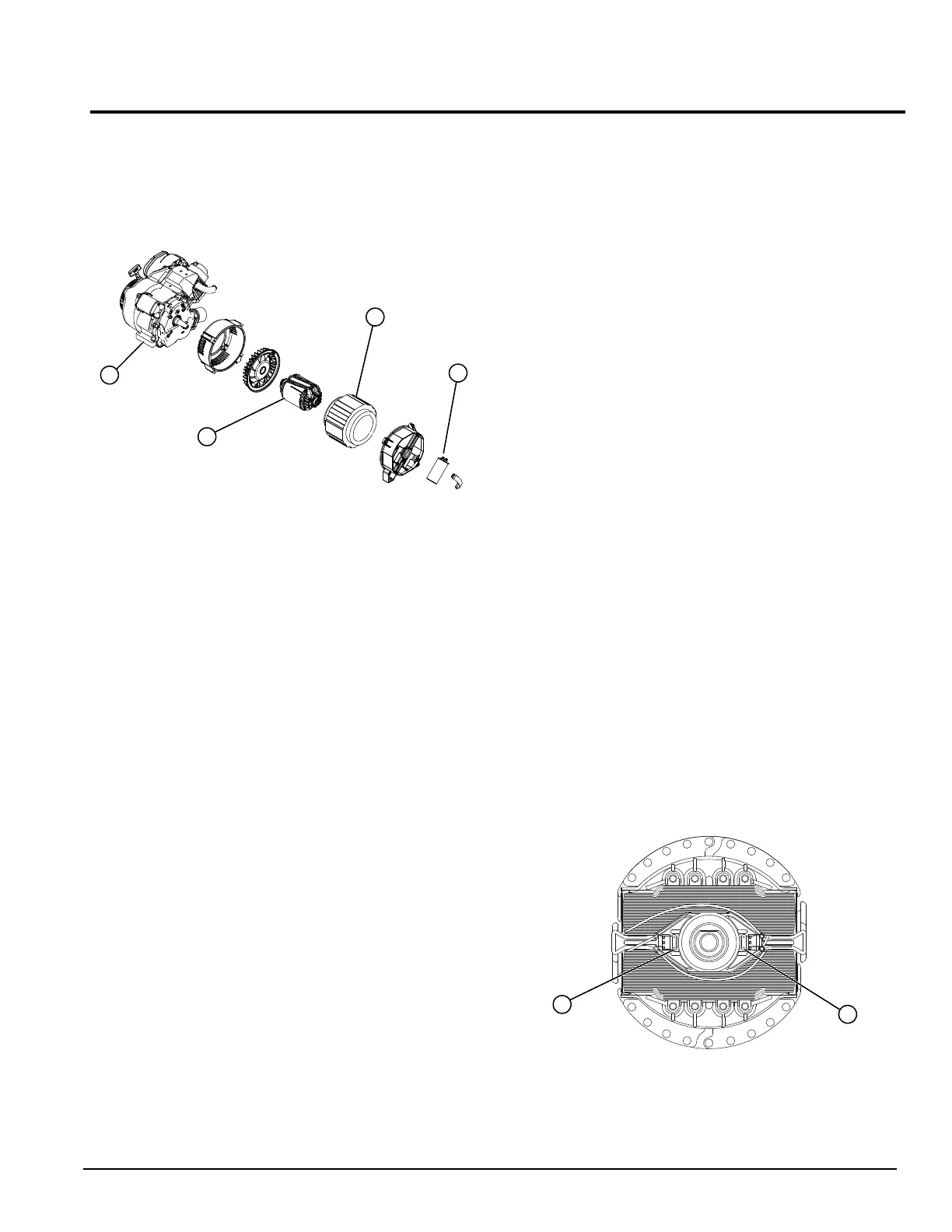

See Figure 1-2. The 2-pole rotor must be operated at

3600 rpm to supply a 60 Hertz AC frequency. The term

“2-pole” means the rotor has a single north magnetic pole

and a single south magnetic pole. It spins freely inside

the stator can and is excited by the charging and

discharging of the capacitor. It has two diodes (A and B)

that rectify voltage induced from the Excitation winding to

DC voltage. Each winding/pole will have a diode

orientated to create current flow in one direction, and the

other winding/pole will have a diode orientated to create

current flow in the opposite direction. This creates a

North and South pole. The rotor bearing is pressed onto

the end of the rotor shaft. The tapered rotor shaft is

mounted to a tapered crankshaft and is held in place with

a single through bolt.

NOTE: Some Rotors have a magnet placed inside the

laminations to help excite the rotor after it's been left idle

for a long period of time.

Figure 1-2. Rotor and Diodes

A. Engine

B. Rotor

C. Stator

D. Capacitor

A

B

C

D

004967

Loading...

Loading...