Section 5 Engine Diagnostic Tests

34 Diagnostic Repair Manual

Figure 5-18. Engine Ground Harness

Test 28 – Remove Shutdown Wire

General Theory

Wire 18 on all engines is used to shut down the unit when

either the switch is placed in OFF, or a low oil condition

occurred. A ground is applied to the magneto in both

instances which inhibits spark and shuts down unit. If a

short to ground exists on this wire, the engine will be

inhibited from producing spark. This test will check the

integrity of the wire.

Procedure

1. Turn off fuel supply.

2. Remove flywheel cover so magneto is exposed.

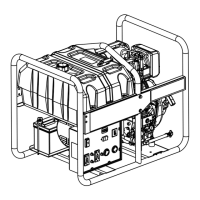

3. See Figure 5-19. Disconnect Wire 18 from

magneto.

4. Repeat Test 20 – Check Ignition Spark.

Figure 5-19. Wire 18 (410 Engine)

Results

1. If spark now occurs, Wire 18 has a short to ground.

Trace Wire 18 back to START-RUN-STOP switch

and Oil Pressure Module (if equipped).

2. If spark still does not occur, refer to flow chart.

Test 29 – Check / Adjust Governor

(208/389/420cc Non-EFI Engine)

Rotor operating speed and AC output frequency are

proportional. The generator delivers a frequency of 60

Hertz at 3600 Rotor rpm or 62 Hertz at 3720 Rotor rpm.

The Voltage Regulator should be adjusted to deliver 120

VAC (line-to-neutral) at a frequency of 60 Hertz or 124

VAC (line-to-neutral at 62 Hertz. It is apparent if governed

speed is high or low, AC frequency and voltage will be

correspondingly high or low. Governed speed at no-load

is usually set slightly above rated speed of 60 Hertz (to

62 Hertz) to prevent excessive rpm, frequency, and

voltage droop under heavy electrical loading.

Procedure

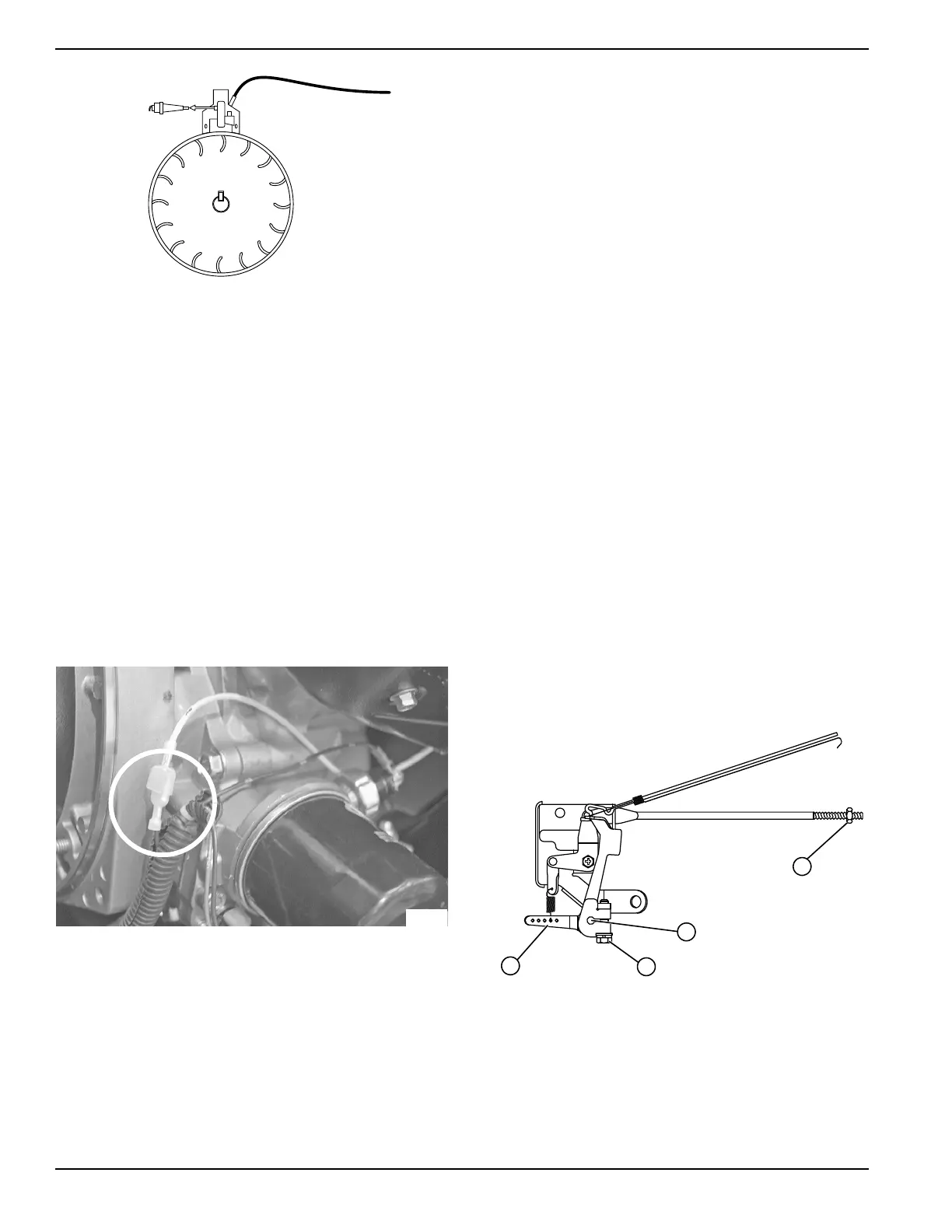

See Figure 5-20.

1. Loosen governor clamp bolt (A).

2. Push Spring end of governor lever (B) clockwise to

wide open throttle position.

a. Hold governor lever at wide open throttle an

d,

with

a pair of pliers, rotate governor shaft (C

)

fully c

lockwise (CW). Use minimum amount

of

fo

rce against governor shaft.

b. While holding governor shaft fully clockwis

e

an

d the governor lever at wide open thro

ttle,

tighte

n governor clamp bolt (A) to 70 inch-

pounds (8 Nm).

3. Start engine. Let stabilize and warm up at no-load.

4. Turn adjuster nut (D) to obtain frequency reading of

62 Hertz.

5. Determine if governor spring is properly located in

slot of governor lever.

Figure 5-20. Governor Adjustment (220/410 Engine)

6. After repositioning spring on lever slot, check

frequency reading and, if necessary, adjust

adjuster nut to obtain 62 Hertz at no-load.

7. When frequency is correct at no-load, check AC

voltage reading. If voltage is incorrect, the voltage

regulator may require adjustment. See Test 12 –

Adjust Voltage Regulator.

Loading...

Loading...