GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

10

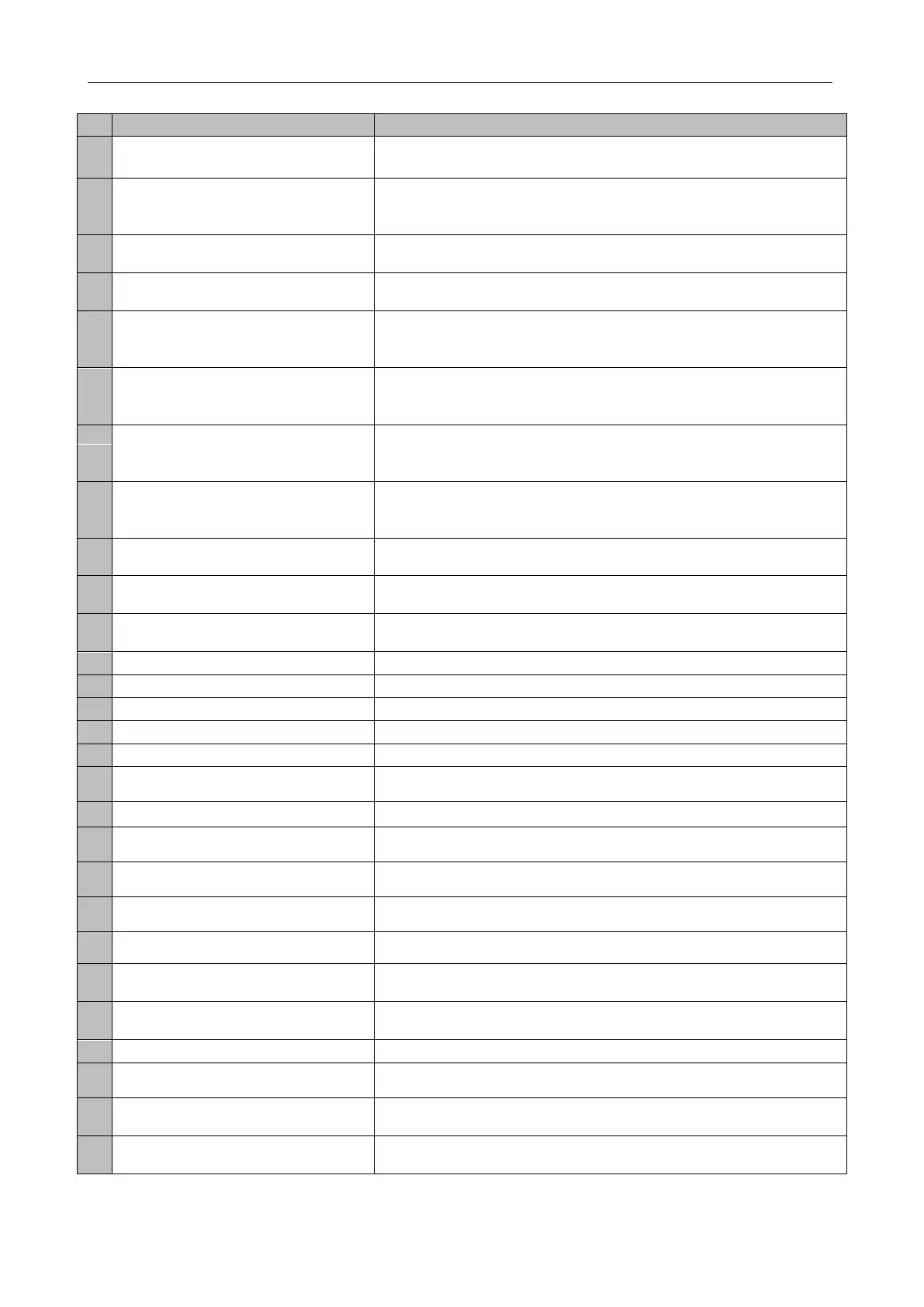

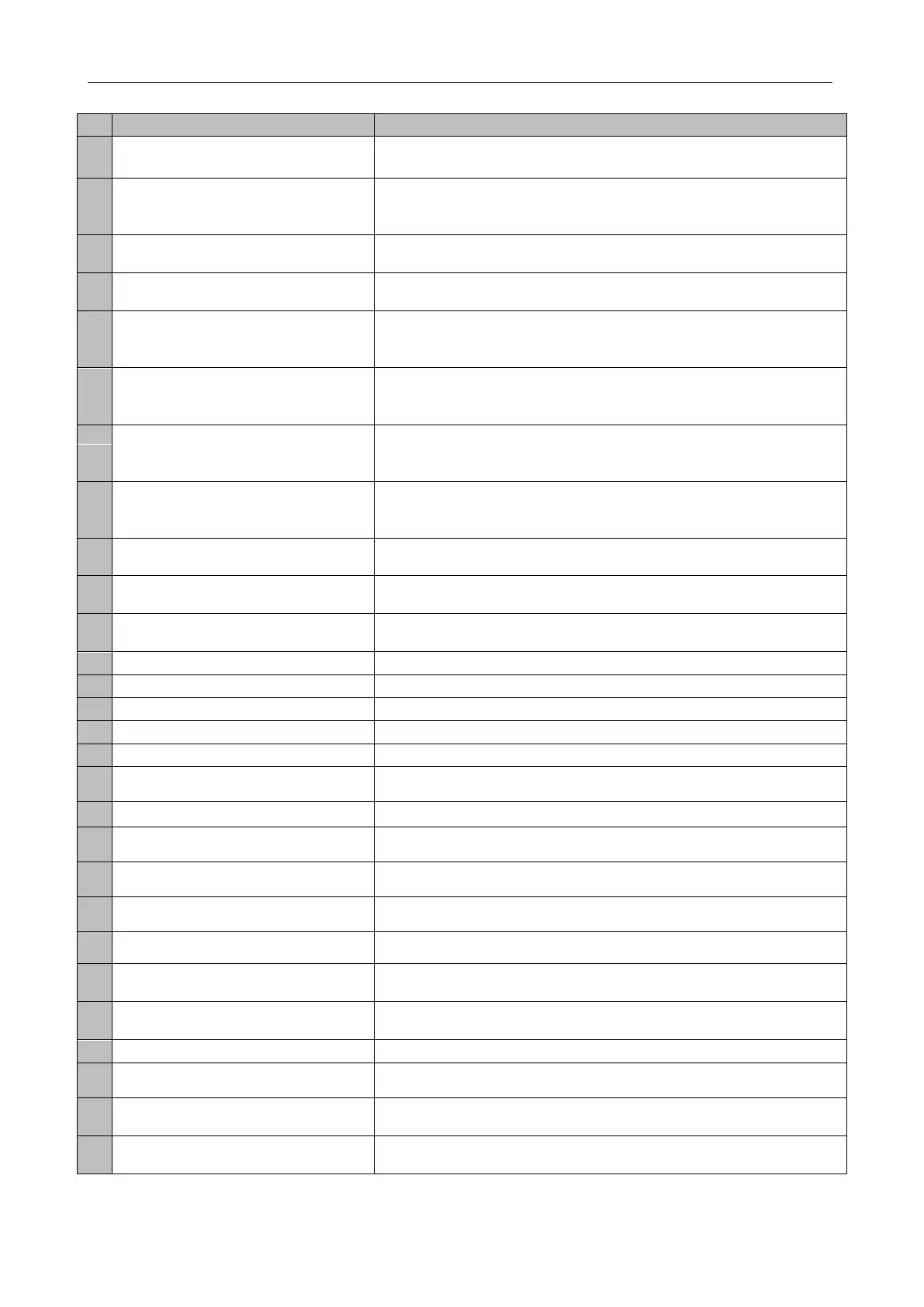

3.3 Names and Main Functions of Components

Adjusts its own rotational speed based on the actual requirement of the

system to implement capacity control.

Maintains a proper oil temperature in the compressor when the

compressor is in standby status, ensuring the reliability during

compressor startup.

Compressor casing-top temperature

sensor

Detects a compressor's exhaust gas temperature for compressor

control and protection.

Exhaust pipe temperature sensor of

compressor

Detects a compressor's exhaust gas temperature for compressor

control and protection.

High-pressure circuit breaker

Protects a compressor by sending feedback signal to stop the system

when the compressor's discharge temperature exceeds the operating

value of high-pressure circuit breaker.

Separates the gas and oil in the system to ensure compressor

reliability.

Equalizes the oil for all modules in the case of excess oil in the current

module when multiple modules are arranged in parallel, thus ensuring

the system reliability.

Heat tape of oil balance device

Maintains a proper oil temperature in the compressor when the

compressor is in standby status, ensuring the reliability of compressor

startup.

Prevents high-pressure gas from entering the compressor and fast

balances the suction pressure and discharge pressure in a compressor.

Detects the high pressure value in the system in real time mode for

compressor protection and other control functions.

Used for the switching between the cooling and heating functions of

system IDU.

Used for outdoor heat exchange.

Strengthens heat exchanging.

Defrosting temperature sensor

Used for defrosting detection.

Electronic expansion valve for heating

Controls refrigerant adjustment in heating mode.

Controls refrigerant flow direction.

Subcooler electronic expansion valve

Controls the degree of subcooling of tube refrigerant when the system

is running in cooling mode, and reduces the capacity loss on pipes.

Controls the degree of subcooling of tube.

Liquid outlet temperature sensor of

subcooler

Detects tube temperature.

Inlet temperature sensor of gas-liquid

separator

Detects the inlet temperature of gas-liquid separator to prevent the

system from running when the refrigerant flows back to the compressor.

Gas outlet temperature sensor of

subcooler

Detects gas temperature of subcooler.

Detects system low pressure to avoid extra-low operating pressure.

Separate gas and liquid to prevent the system from running when the

refrigerant flows back to the compressor.

Outlet temperature sensor of

gas-liquid separator

Detects internal status of gas-liquid separator to further control the

compressor suction performance.

Used for oil balance control among modules.

Used for oil balance control among modules and avoid reverse flow of

oil.

Avoids over-high pressure caused by pipeline blind spot.

Used for oil balance control among modules.

Loading...

Loading...