GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

87

simultaneously for pipes on outdoor sides and cannot be increased for pipes on one side.

8.2 VACUUMIZATION AND DESICCATION FOR THE SYSTEM

8.2.1 Requirements on the Vacuum Pump

The vacuum pump for different refrigerant systems cannot be the same.

The ultimate vacuum degree of the vacuum pump should reach -0.1 Mpa.

The air discharge capacity of the vacuum pump must be greater than 4 L/S.

The precision of the vacuum pump must be greater than 0.02 mmHg.

The system vacuum pump must be equipped with a check valve.

8.2.2 Procedure and Precautions for Vacuumization and Desiccation

8.2.2.1 Procedure

(1) Before vacuumization, ensure that the stop valves of the gas and liquid pipes are turned off.

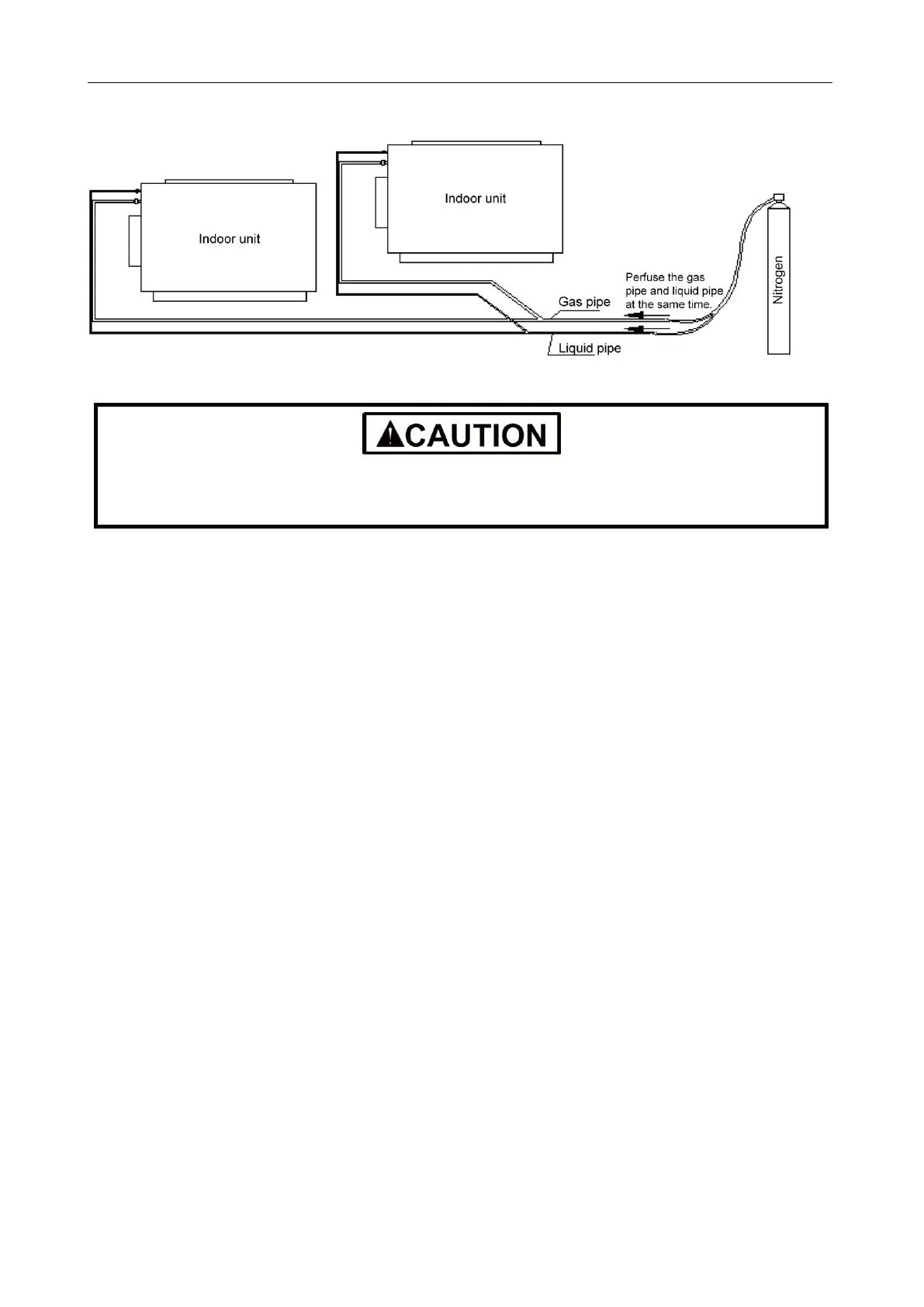

(2) Use the perfusing duct to connect the regulator valve and vacuum pump to detection connectors

of the gas pipe and liquid pipe.

(3) Vacuumize for 4 hours and check whether the vacuum degree reaches -0.1 MPa or more. If not,

leakage may exist. Perform leakage check again. If no leakage exists, continue to vacuumize for 2

hours.

(4) If the vacuum degree cannot be kept after vacuumization is performed for twice, there may be

water in the pipe when it is confirmed that no leakage exists. In this case, discharge water by means of

vacuum breaking. Perfuse nitrogen at 0.05 MPa to the pipe. Vacuumize for 2 hours and keep vacuuming

for 1 hour. If the vacuum degree of -0.1 MPa cannot be reached, repeat this operation till water is

discharged.

(5) After vacuumization, turn off the regulator valve and keep for 1 hour. Ensure that the pressure of

Before performing the air-tightness test, do not conduct insulation or wrapping at the welding

joints,Otherwise, leak source cannot be detected quickly.

Loading...

Loading...