80DWFK6HULHV'&

,QYHUWHU6HUYLFH0DQXDO

74

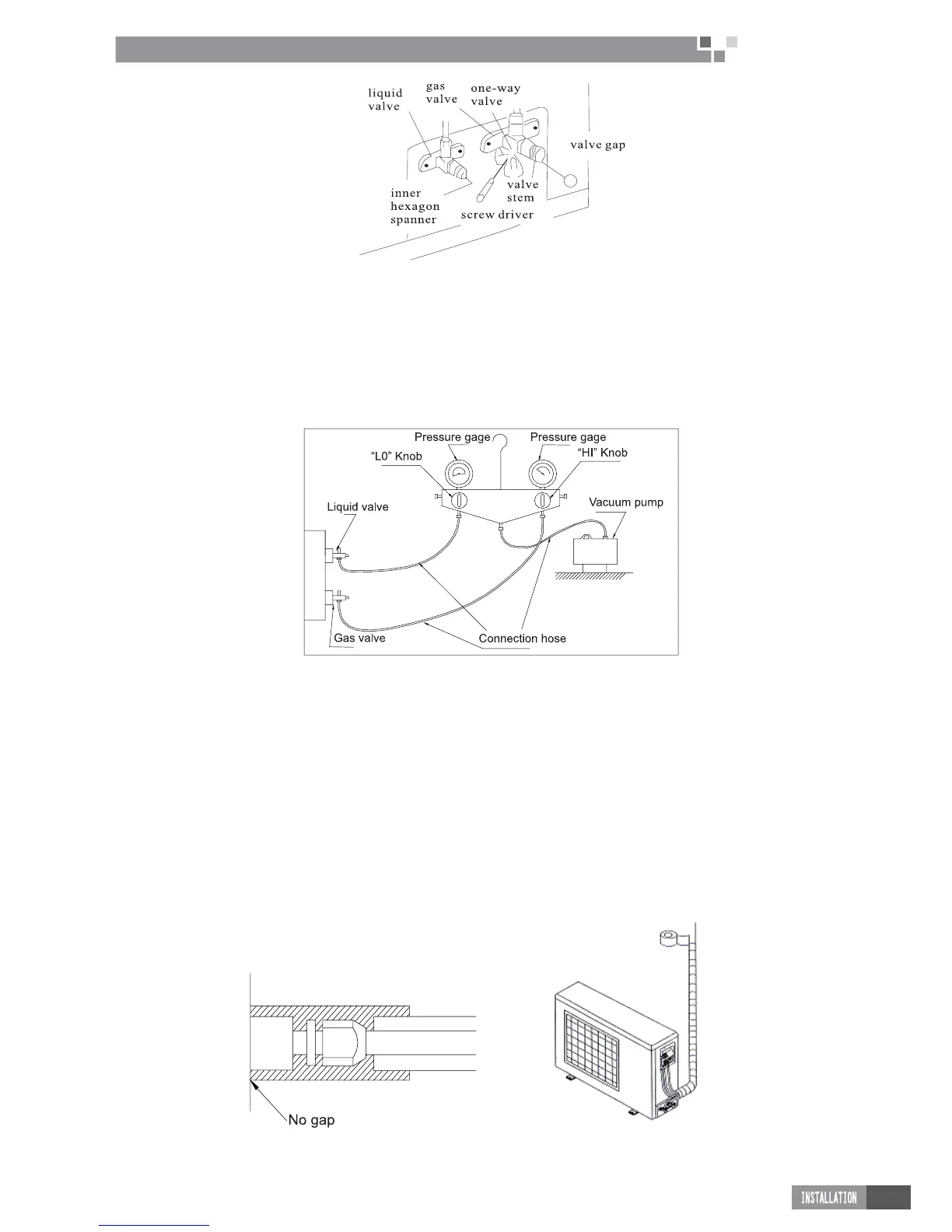

Figure 3-1-4

Ɣ

Tighten the valve cap and then use soap water or leakage detector to check the connection between

outdoor unit and pipe for any leakage.

Caution:

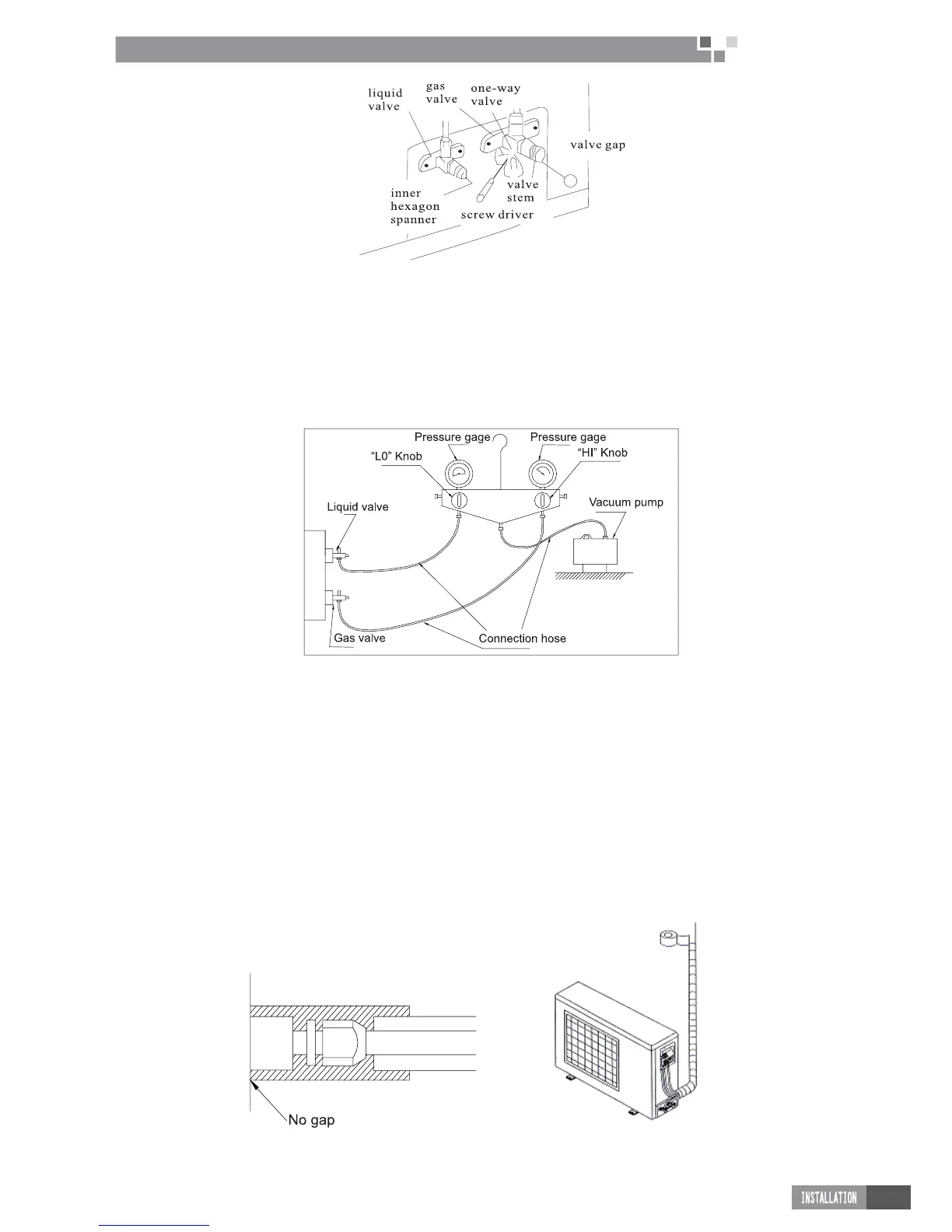

If possible, it is best to discharge the air out of the machine from the valve by using vacuum pump. To

establish vacuum by using vacuum pump, please operate as follows:

Ɣ

Take out the nut cover of the inlet for refrigerant.

Ɣ

Connect the tube of the vacuum watch with the vacuum pump, having the low-pressure end linking to

the inlet for refrigerant. (As shown in Figure 3-1-5)

Figure 3-1-5

Ɣ

Starting the vacuum pump, when the indicator turns to-1 bar, closing the low pressure handle and

stopping vacuumize. Keep for 15 minutes, ensuring the pressure of the vacuum watch remains.

Ɣ

Take out the valve cover of the gas valve together with the liquid valve.

Ɣ

Loosing the cord of liquid valve until the pressure rise to 0 bar.

Ɣ

Dismantle the tube from the cover of the inlet for refrigerant then, tighten the cover.

Ɣ

Loose the valve cord of the gas valve as well as the liquid valve entirely.

Ɣ

Tighten the valve cover of the gas valve and liquid valve so as to check whether leakage occurred.

c. Installation of Protective Layer of Connecting Pipe

Ɣ

To avoid generation of condensate on the connecting pipe and avoid leakage, the big pipe and the small

pipe of the connecting pipe must be covered by thermal insulation materials, be bundled by adhesive tape, and

be isolated from air.

Ɣ

The joint connecting to the indoor unit must be wrapped by thermal insulation material. There shall be

no gap between the connecting pipe joint and the wall of the indoor unit. Refer to Figure 3-1-6.

Figure 3-1-6 Figure 3-1-7

Loading...

Loading...