BF15DmBFZOD

OIL

PRESSURE TEST

1) Remove the engine cover and check the engine oil level

2)

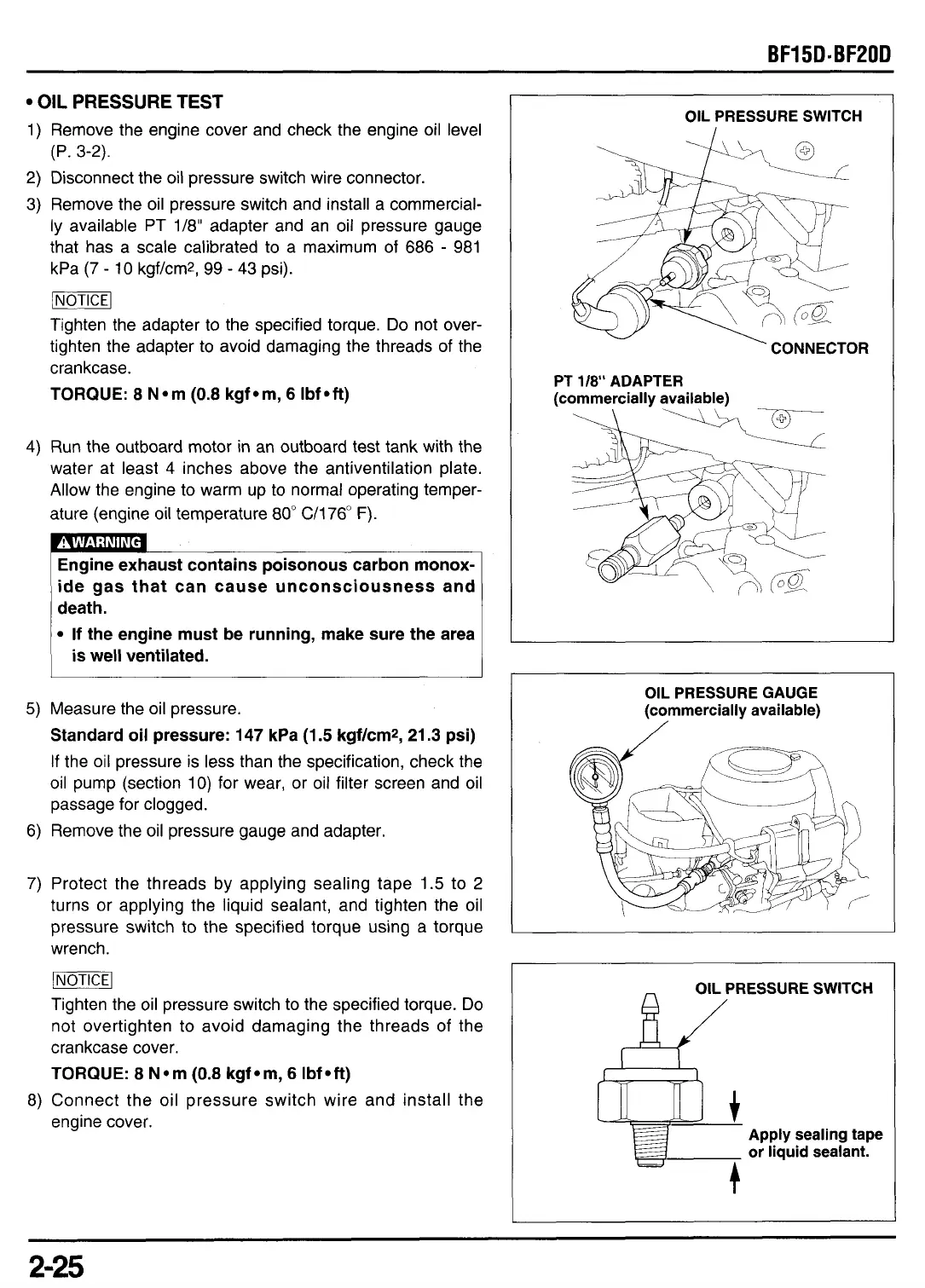

Disconnect the oil pressure switch wire connector.

3)

Remove the oil pressure switch and install a commercial-

ly available

PT

1/8" adapter and an oil pressure gauge

that has a scale calibrated

to

a maximum

of

686

-

981

kPa

(7

-

10 kgf/cm2, 99

-

43

psi).

Tighten the adapter

to

the specified torque.

Do

not over-

tighten the adapter

to

avoid damaging the threads of the

crankcase.

TORQUE:

8

Nom

(0.8

kgfom,

6

Ibfoft)

(P.

3-2).

/NOTICE1

4

Run

the outboard motor

in

an outboard test tank with the

water at least

4

inches above the antiventilation plate.

Allow the engine

to

warm up

to

normal operating temper-

ature (engine oil temperature 80" C/176"

F).

Engine exhaust contains poisonous carbon monox-

ide gas that can cause unconsciousness and

death.

If

the engine must be running, make sure the area

is

well ventilated.

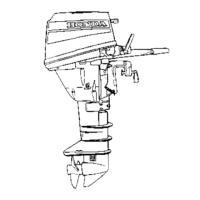

5)

Measure the oil pressure.

Standard oil pressure:

147

kPa (1.5 kgf/cm2,21.3 psi)

If

the oil pressure is less than the specification, check the

oil pump (section 10) for wear, or oil filter screen and oil

passage for clogged.

6)

Remove the oil pressure gauge and adapter.

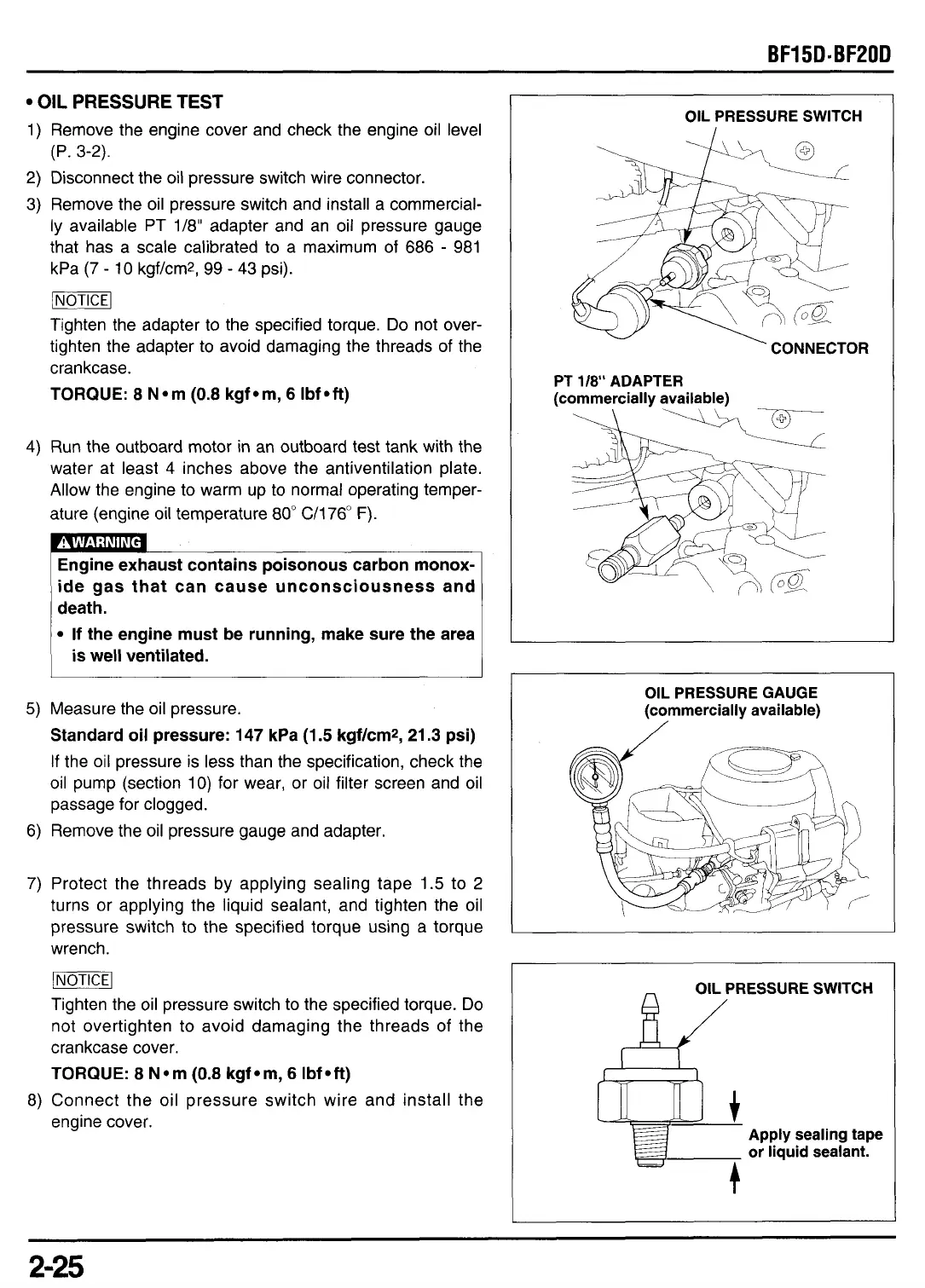

7)

Protect the threads by applying sealing tape 1.5

to

2

turns or applying the liquid sealant, and tighten the oil

pressure switch to the specified torque using a torque

wrench.

/NOTICE1

Tighten the oil pressure switch

to

the specified torque.

Do

not overtighten

to

avoid damaging the threads of the

crankcase cover.

TORQUE:

8

Nom

(0.8

kgfom,

6

Ibfoft)

engine cover.

8) Connect the oil pressure switch wire and install the

OIL

PRESSURE SWITCH

CONNECTOR

PT

118'

ADAPTER

(commercially available)

OIL

PRESSURE GAUGE

(commercially available)

/

OIL

PRESSURE SWITCH

@/

2-25

Loading...

Loading...