COOLING SYSTEM

RADIATOR CAP/SYSTEM PRESSURE

INSPECTION

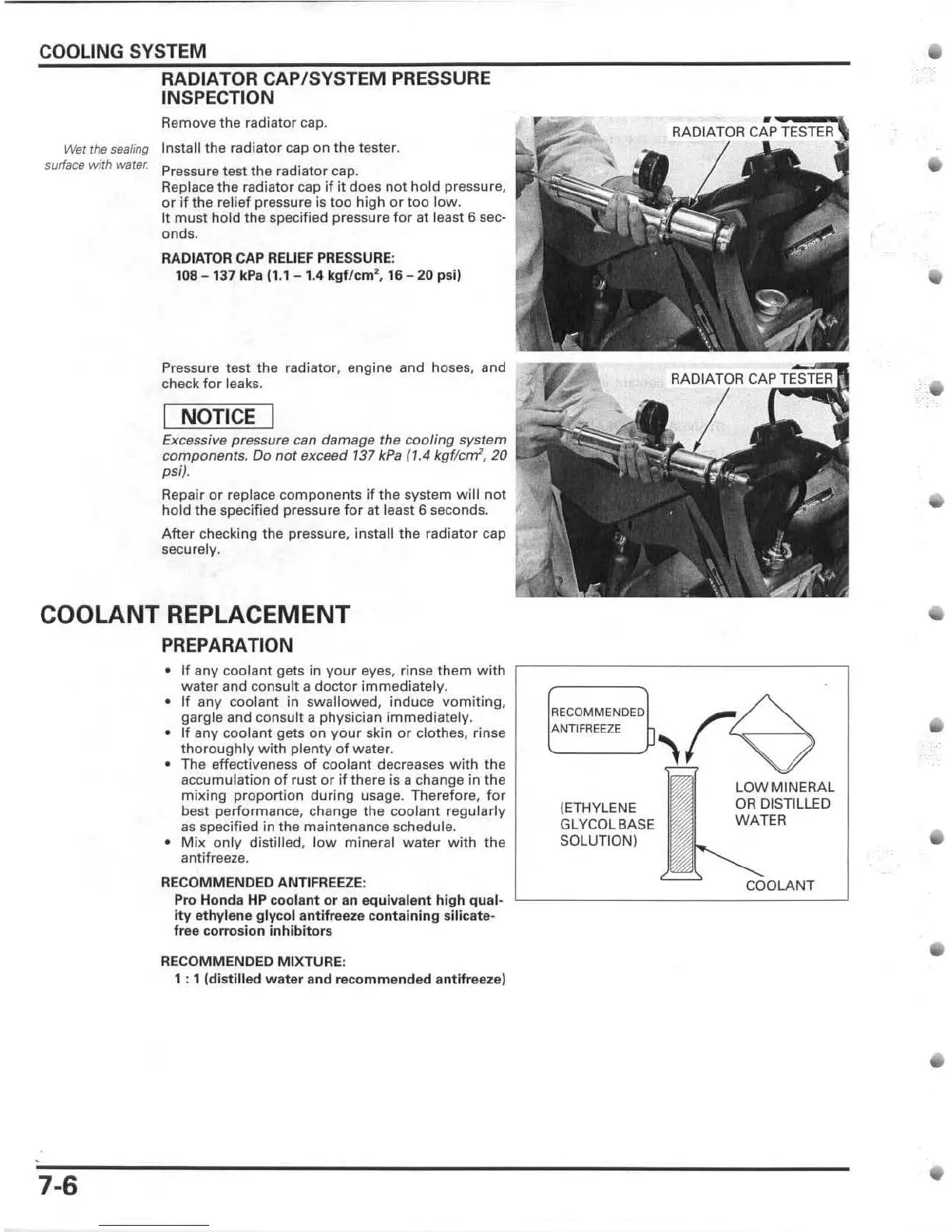

Remove the radiator cap.

Wet the sealing Install the radiator cap on

the

tester.

surface

wi

th

w

af

er.

Pressure

test

the

radiator cap.

Rep

lace the radiator cap

if

it does

not

hold pressure,

or

if

the relief pressure is too high

or

too

low.

It

must

hold the specified pressure

for

at least 6 sec-

onds.

RADIATOR

CAP

RELIEF

PRESSURE

:

108 - 137 kPa

(1

.1 - 1.4

kgf/cm

l,

16 -

20

psi)

Pressure test

the

radiator,

engine

and

hoses, and

check

for

leaks.

I

NOTICE

I

Excessive pressure can damage the cooling

system

components. Do not exceed 137

kPa

(1.4

kgfknr.

20

psi).

Repair

or

replace components

if

the system

will

not

hold

the

specifi

ed

pressure

for

at least 6 seconds.

After checking the pressure, install the radiator cap

securely.

COOLANT REPLACEMENT

PREPARATION

•

If

any

coo

l

ant

gets

in

your eyes, rinse

them

with

,------

-

--------

-

--,

7-6

water

and consu

lt

a

doctor

immediately.

•

If

any coolant in

swallowed,

induce

vomiting,

gargle and consult a physician immediately.

• If

any

coolant gets on yo

ur

sk

in

or

clothes, rinse

thoroughly

with

plenty

of

water.

• The effectiveness of coolant

decreases

with

the

accumu

lati

on

of

rust

or

if

th

ere is a

change

in

the

mixing

pr

oportion

during

usage. Therefore,

for

best

performance,

change

the

coolant

regularly

as

specified in the maintenance schedule.

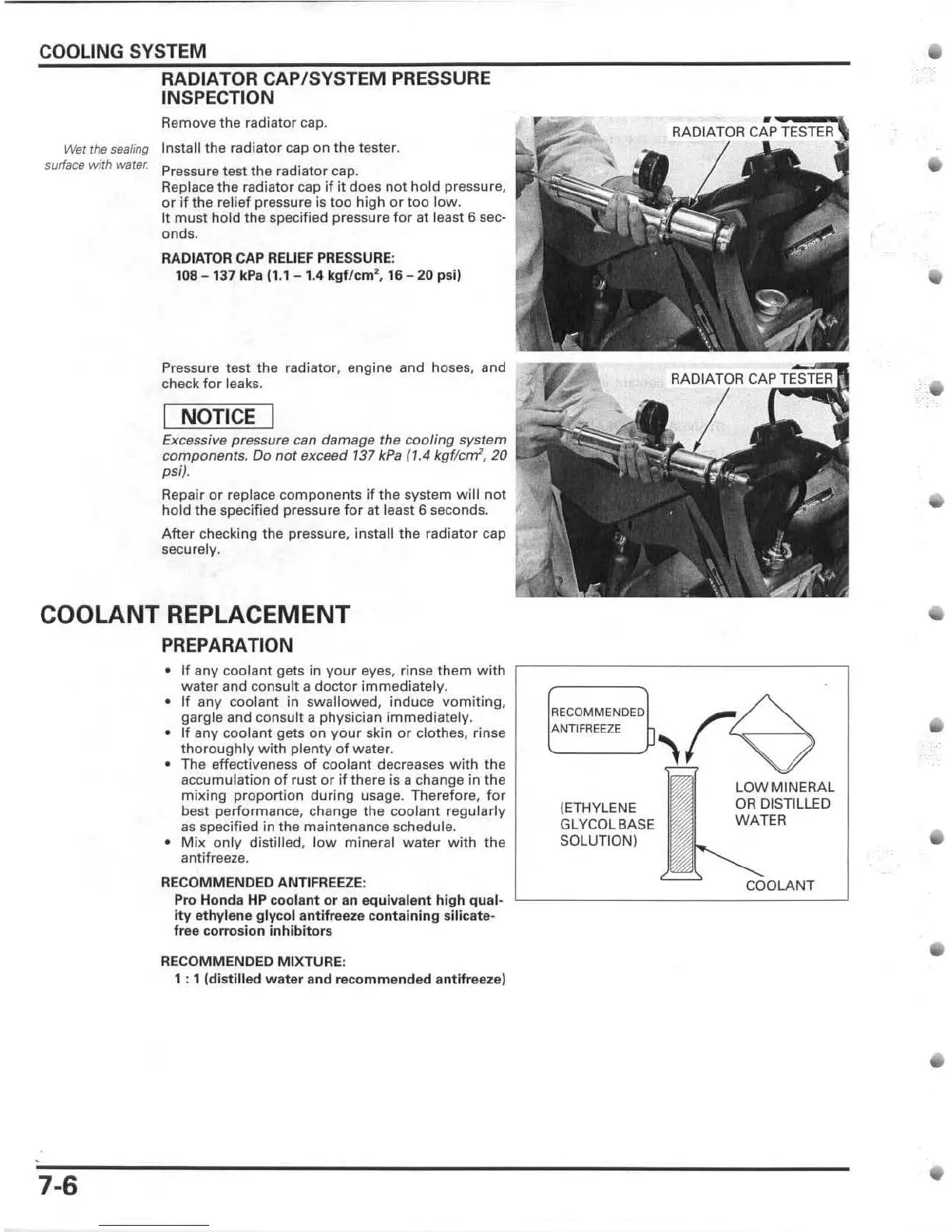

•

Mix

only distilled,

low

mineral water

with

the

antif

r

eeze.

RECOMMENDED

ANTIFREEZE

:

Pro Honda

HP

coolant

or

an equivale

nt

high qual-

i

ty

ethylene glycol antifr

eeze

containing

si

li

cate-

free corrosion inhibitors

RECOMMENDED

MIXTURE

:

1 : 1

1d

istilled

water

and r

eco

mm

e

nded

antifreeze)

(ETHYLENE

GLYCOLBASE

SOLUTION)

LOW

MINERAL

OR

DISTILLED

WATE

R

COOLANT

Loading...

Loading...